- May 27, 2020

- 6

- 4

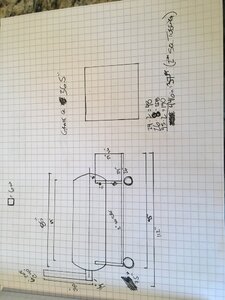

Started my first offset smoker project this week. It'll have a 150gal cook chamber (85in long - 24in diameter = 35,371cu in), a 26in X 24in X 26in semi insulated firebox (16,224cu in), and planning on having a 6in diameter/40in tall smoke stack (1,131cu in). Learning how to weld/fabricate on this project, so there's a boat-load of trial and (mostly) error. Weld distortion....

So far this week:

- Frame cut and welded (1/8in thick - 2in square tubing)

- Casters mounted to 1/4" plate

- Tank marked up for cuts

Thoughts and advice welcomed!

So far this week:

- Frame cut and welded (1/8in thick - 2in square tubing)

- Casters mounted to 1/4" plate

- Tank marked up for cuts

Thoughts and advice welcomed!