Last Summer I had purchased one of the original Oklahoma Joe's that was made in Perry Oklahoma. It 1/4" and the welds on it are impeccable. The smoker itself is in great shape and has no rust what so ever. One thing that I am having problems with is the heat distribution across the grate. I have a baffle plate installed and the temperature difference was over 100 degrees from side to side. Tried lowering the exhaust with aluminum duct and the same result. When the smoker is ran without the baffle plate the temperature on the firebox because over 300 no matter how small the fire.

I'm running out of things to try and was wondering what your inputs would be on how to fix this? I'm almost at my wits end and want to sell it, but I don't want to downgrade if I do. Any help is much appreciated.

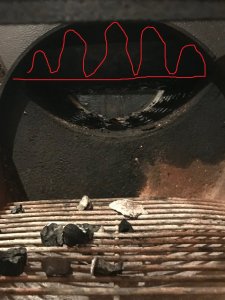

Also on the pictures excuse me for how dirty it is... It hasn't had its spring cleaning yet...

I'm running out of things to try and was wondering what your inputs would be on how to fix this? I'm almost at my wits end and want to sell it, but I don't want to downgrade if I do. Any help is much appreciated.

Also on the pictures excuse me for how dirty it is... It hasn't had its spring cleaning yet...