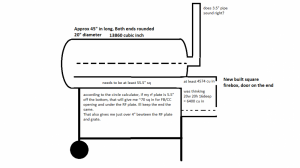

my brother and I just finished our first reverse flow build, and had a small issue while burning it out the first time.

We couldn't get even temps across the grates. It was running 25 - 50 degrees difference from end to end. Ill add some pics so you can see how it's built.

Any ideas would be helpful.

We couldn't get even temps across the grates. It was running 25 - 50 degrees difference from end to end. Ill add some pics so you can see how it's built.

Any ideas would be helpful.