For my first ever sausage links, I chose Chef Willie's hot link recipe. Here's the recap....

First grind. 5 lbs of pork butt

This is after the spices were added, the second grind and a night in the refr.

Time for the stuffing. My grandson assisted even tho he was still finishing his breakfast. I used Lem

32 to 35 mm hog casings. I need to learn how to control the size of the stuffed casing. I didn't know it

but over stuffing was going to cause problems later.

Time to make links... I burst the casing two times due to the over stuffing while trying to twist links.

That is what caused the 2 and 3 link separates. I finally decided to just twist once and then tie

each link off with butcher twine. Also had trouble keeping the length of each link reasonably close.

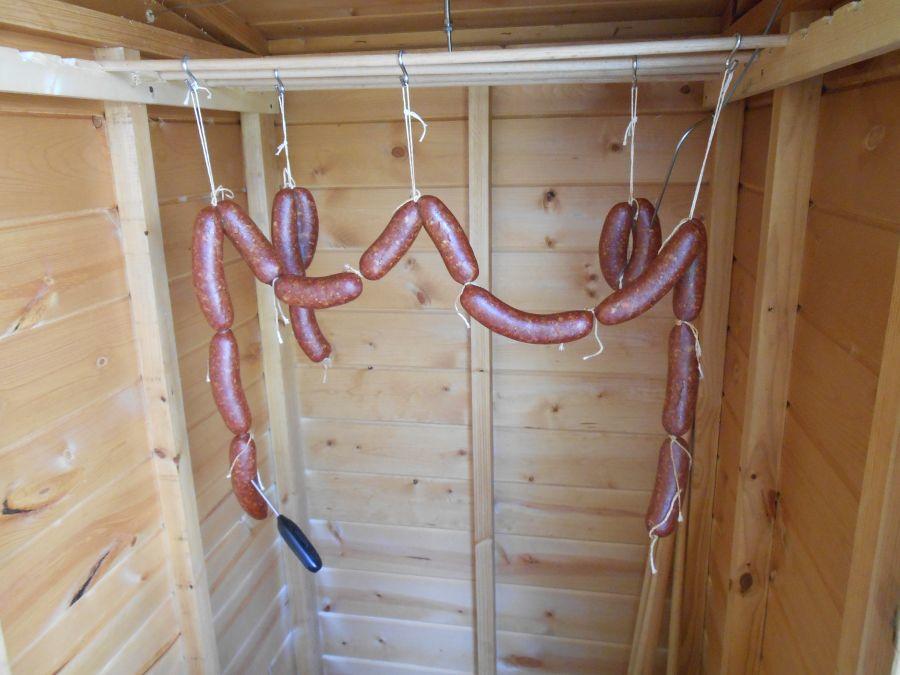

Into the home brew smoke house that used two 110 volt hot plates as a heat source. One is controlled

by a home brew JLD 612 P.I.D. controller. The other is on standby. There is a temp probe in one link on

the second row on the right side.

Started the smoker at 120 to dry the links, raised the temp to 130 and started the Amazn tube smoker loaded

with hickory pellets. Smoked for about 2.5 hours while raising the smoker temp 10 degs per hour.

Had intended to hang the links another way but due to the aforementioned problems had to resort to this

arrangement. It did however get the job done.

When I stopped the smoke, I checked another link that was on the other side of the smoke house to

verify internal temp. Both probed links were withing 2 degs of each other but were still a long ways

from my target of 155. So, I decided to poach.

Didn't get a picture of the poaching but here they are in the ice bath afterward.

Using my engineering ability.... I constructed a blooming station.

Couple of hours later I vacuum packed them for the freezer.

Finally, the taste test. They were spicy, had a reasonable amount of moisture and the casings were

not too tough. I need to learn how to control the stuffed diameter of the casing and how to twist links

so they're reasonably close to the same length. Overall, I'm satisfied my setup will produce a reasonable

product if the operator (namely me) can pick up some sausage making skills. I'd appreciate any suggestions

on how to address my deficiencies.

P.S. Hope this post wasn't too long.

First grind. 5 lbs of pork butt

This is after the spices were added, the second grind and a night in the refr.

Time for the stuffing. My grandson assisted even tho he was still finishing his breakfast. I used Lem

32 to 35 mm hog casings. I need to learn how to control the size of the stuffed casing. I didn't know it

but over stuffing was going to cause problems later.

Time to make links... I burst the casing two times due to the over stuffing while trying to twist links.

That is what caused the 2 and 3 link separates. I finally decided to just twist once and then tie

each link off with butcher twine. Also had trouble keeping the length of each link reasonably close.

Into the home brew smoke house that used two 110 volt hot plates as a heat source. One is controlled

by a home brew JLD 612 P.I.D. controller. The other is on standby. There is a temp probe in one link on

the second row on the right side.

Started the smoker at 120 to dry the links, raised the temp to 130 and started the Amazn tube smoker loaded

with hickory pellets. Smoked for about 2.5 hours while raising the smoker temp 10 degs per hour.

Had intended to hang the links another way but due to the aforementioned problems had to resort to this

arrangement. It did however get the job done.

When I stopped the smoke, I checked another link that was on the other side of the smoke house to

verify internal temp. Both probed links were withing 2 degs of each other but were still a long ways

from my target of 155. So, I decided to poach.

Didn't get a picture of the poaching but here they are in the ice bath afterward.

Using my engineering ability.... I constructed a blooming station.

Couple of hours later I vacuum packed them for the freezer.

Finally, the taste test. They were spicy, had a reasonable amount of moisture and the casings were

not too tough. I need to learn how to control the stuffed diameter of the casing and how to twist links

so they're reasonably close to the same length. Overall, I'm satisfied my setup will produce a reasonable

product if the operator (namely me) can pick up some sausage making skills. I'd appreciate any suggestions

on how to address my deficiencies.

P.S. Hope this post wasn't too long.