- Apr 19, 2019

- 11

- 8

I wanted to share with everyone the new smoker I built. I couldn't find very little online in the way of offset brick smokers so I thought my experience might help someone in the future. A few things to consider

- I'm in no way a brick mason, this was my first attempt at any masonry, in the end it turned out better than I could have hoped for, but there was a lot of slow work

- I do have some experience welding and fabricating, which helped a great deal

-I have an engineering background, so like all other engineers who think about things for a long time.... some of this is 100% overthought, over done, and overbuilt.

-please ask any questions you want, I'm on the forum and will try to respond.

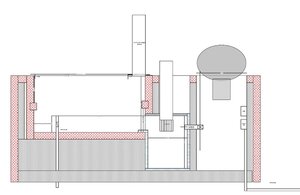

My plan was to build an brick, offset smoker, with the ability to have some gravity fed ability, but also burn with a normal firebox. here is the initial design I made in Visio, and the final product,

- I'm in no way a brick mason, this was my first attempt at any masonry, in the end it turned out better than I could have hoped for, but there was a lot of slow work

- I do have some experience welding and fabricating, which helped a great deal

-I have an engineering background, so like all other engineers who think about things for a long time.... some of this is 100% overthought, over done, and overbuilt.

-please ask any questions you want, I'm on the forum and will try to respond.

My plan was to build an brick, offset smoker, with the ability to have some gravity fed ability, but also burn with a normal firebox. here is the initial design I made in Visio, and the final product,