Hi there, everybody. Long-time meat smoker (on assorted cookers, most recently a cheap-but-effective Charbroil offset) and forum lurker, but now a member.

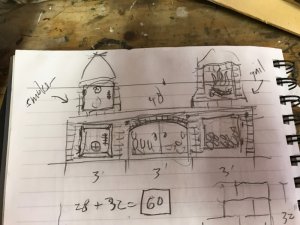

Something I've long wanted to do, and have just started, is to build a brick smoker. So with about 1,000 bricks left over from a home addition, I decided to go after it. I'm posting the first few pix here to share the project and also to get some ideas and input from others with brick pit experience. I've searched the web high and low, and there's not much out there for projects like this. So mostly I'm using experience and intuition to design and build it. Oh, it's my first brick project, too! Had one lesson from my mason. After that, it's just practice, and knowing how to read a mason's rule. The base is about done; next comes the countertop, then the smoker body on the top left and an enclosed grill on the top right, and all the metalwork (doors, racks, etc).

UPDATE: Brick pit Part II

Well, it took three months, but my brick pit is complete! (Photos 18 and on).

When we left off, I had finished the lower portion, and was about to pour the concrete countertop and start constructing the top, which consists of the smoke chamber on the left and the Tuscan grill on the right. Those are capped off with a concrete countertop, poured in place (1200 lbs!). Then I designed and built the chimneys (including a damper system for the smoker), fabricated the doors for the fire box and smoke box (including forging the hinges and handles), and built wooden doors (with forged hinges) for the dry storage under the Tuscan grill. Lastly, I fabricated racks for both cookers - expanded metal for the smoker and 1/4 inch rod for the grill (with forged Italianesque handles) I finished it in late July and have had one good smoking on it plus half a dozen excellent steaks on the Tuscan grill. Both sides work like a charm!

The unit features four different brick patters: standard running bond, English garden bond, Flemish bond, and basketweave decorative panels at each end. Those were made in forms, then attached with thinset and mortar piped in around the edges.

You may note that there's no vent in the firebox door. I opted to just leave the door cracked a bit when cooking rather than hack a hole in the 1/4 inch steel. If I can find someone with a CNC plasma cutter or water jet, I may still do a vent.

Something I've long wanted to do, and have just started, is to build a brick smoker. So with about 1,000 bricks left over from a home addition, I decided to go after it. I'm posting the first few pix here to share the project and also to get some ideas and input from others with brick pit experience. I've searched the web high and low, and there's not much out there for projects like this. So mostly I'm using experience and intuition to design and build it. Oh, it's my first brick project, too! Had one lesson from my mason. After that, it's just practice, and knowing how to read a mason's rule. The base is about done; next comes the countertop, then the smoker body on the top left and an enclosed grill on the top right, and all the metalwork (doors, racks, etc).

UPDATE: Brick pit Part II

Well, it took three months, but my brick pit is complete! (Photos 18 and on).

When we left off, I had finished the lower portion, and was about to pour the concrete countertop and start constructing the top, which consists of the smoke chamber on the left and the Tuscan grill on the right. Those are capped off with a concrete countertop, poured in place (1200 lbs!). Then I designed and built the chimneys (including a damper system for the smoker), fabricated the doors for the fire box and smoke box (including forging the hinges and handles), and built wooden doors (with forged hinges) for the dry storage under the Tuscan grill. Lastly, I fabricated racks for both cookers - expanded metal for the smoker and 1/4 inch rod for the grill (with forged Italianesque handles) I finished it in late July and have had one good smoking on it plus half a dozen excellent steaks on the Tuscan grill. Both sides work like a charm!

The unit features four different brick patters: standard running bond, English garden bond, Flemish bond, and basketweave decorative panels at each end. Those were made in forms, then attached with thinset and mortar piped in around the edges.

You may note that there's no vent in the firebox door. I opted to just leave the door cracked a bit when cooking rather than hack a hole in the 1/4 inch steel. If I can find someone with a CNC plasma cutter or water jet, I may still do a vent.

Attachments

-

1. The plan.jpg509.2 KB · Views: 2,461

1. The plan.jpg509.2 KB · Views: 2,461 -

3. Pad ready to pour.jpg293.5 KB · Views: 2,445

3. Pad ready to pour.jpg293.5 KB · Views: 2,445 -

4. Pad done.JPG257.7 KB · Views: 2,367

4. Pad done.JPG257.7 KB · Views: 2,367 -

6. fire box.jpg628.2 KB · Views: 392

6. fire box.jpg628.2 KB · Views: 392 -

7 back bricks.jpg259.1 KB · Views: 396

7 back bricks.jpg259.1 KB · Views: 396 -

9 back complete.jpg765.2 KB · Views: 391

9 back complete.jpg765.2 KB · Views: 391 -

10 front 1.jpg662.5 KB · Views: 2,338

10 front 1.jpg662.5 KB · Views: 2,338 -

12 front 3.jpg708.6 KB · Views: 400

12 front 3.jpg708.6 KB · Views: 400 -

14 arch form detail.jpg765.8 KB · Views: 408

14 arch form detail.jpg765.8 KB · Views: 408 -

15 front done 1.jpg819.4 KB · Views: 2,304

15 front done 1.jpg819.4 KB · Views: 2,304 -

16 forms removed.jpg607.9 KB · Views: 394

16 forms removed.jpg607.9 KB · Views: 394 -

17 storage.jpg624.3 KB · Views: 2,250

17 storage.jpg624.3 KB · Views: 2,250 -

18 Basketweave form.jpg662.9 KB · Views: 2,148

18 Basketweave form.jpg662.9 KB · Views: 2,148 -

20 basketweave installed.jpg644.2 KB · Views: 2,147

20 basketweave installed.jpg644.2 KB · Views: 2,147 -

23 locating the cookers.jpg655.8 KB · Views: 2,140

23 locating the cookers.jpg655.8 KB · Views: 2,140 -

24 string poles.jpg572.8 KB · Views: 338

24 string poles.jpg572.8 KB · Views: 338 -

25 string pole detail.jpg488.8 KB · Views: 335

25 string pole detail.jpg488.8 KB · Views: 335 -

26 four courses done.jpg644.3 KB · Views: 2,065

26 four courses done.jpg644.3 KB · Views: 2,065 -

27 Tuscan grill arch form.jpg538.3 KB · Views: 2,021

27 Tuscan grill arch form.jpg538.3 KB · Views: 2,021 -

28 next, the smoker box.jpg605 KB · Views: 345

28 next, the smoker box.jpg605 KB · Views: 345 -

29 concrete block and angle iron rack supports.jpg553.3 KB · Views: 2,063

29 concrete block and angle iron rack supports.jpg553.3 KB · Views: 2,063 -

30 bricks cover the blocks.jpg675 KB · Views: 2,059

30 bricks cover the blocks.jpg675 KB · Views: 2,059 -

31 chimney time.jpg656.4 KB · Views: 1,992

31 chimney time.jpg656.4 KB · Views: 1,992 -

32 foam form guides the bricks.jpg678.7 KB · Views: 1,951

32 foam form guides the bricks.jpg678.7 KB · Views: 1,951 -

33 finished Tuscan grill.jpg686.2 KB · Views: 1,992

33 finished Tuscan grill.jpg686.2 KB · Views: 1,992 -

34 angle iron door frame.jpg588.6 KB · Views: 368

34 angle iron door frame.jpg588.6 KB · Views: 368 -

35 Smoker chimney got flagstone top and shoulders.jpg594.5 KB · Views: 360

35 Smoker chimney got flagstone top and shoulders.jpg594.5 KB · Views: 360 -

37 custom old-world style grate.jpg482.3 KB · Views: 1,881

37 custom old-world style grate.jpg482.3 KB · Views: 1,881 -

38 first steaks!.jpg581 KB · Views: 1,824

38 first steaks!.jpg581 KB · Views: 1,824 -

42 smoker grates.jpg523 KB · Views: 1,937

42 smoker grates.jpg523 KB · Views: 1,937 -

43 building the smokebox doors.jpg513.5 KB · Views: 1,867

43 building the smokebox doors.jpg513.5 KB · Views: 1,867 -

44 latch mechanism.jpg518.3 KB · Views: 1,850

44 latch mechanism.jpg518.3 KB · Views: 1,850 -

47 first fire.jpg512 KB · Views: 373

47 first fire.jpg512 KB · Views: 373 -

48 first ribs.jpg409.3 KB · Views: 1,909

48 first ribs.jpg409.3 KB · Views: 1,909 -

50 wood doors.jpg561 KB · Views: 1,864

50 wood doors.jpg561 KB · Views: 1,864 -

51 hand-forged hinges.jpg557.6 KB · Views: 337

51 hand-forged hinges.jpg557.6 KB · Views: 337 -

52 more hinges.jpg471.2 KB · Views: 333

52 more hinges.jpg471.2 KB · Views: 333 -

53 tuning plates between firebox and smokebox.jpg477 KB · Views: 342

53 tuning plates between firebox and smokebox.jpg477 KB · Views: 342 -

54 Firebox latch detail.jpg517.1 KB · Views: 335

54 Firebox latch detail.jpg517.1 KB · Views: 335 -

55 smokebox doors.jpg527.4 KB · Views: 1,821

55 smokebox doors.jpg527.4 KB · Views: 1,821 -

56 brick decoration.jpg574.6 KB · Views: 331

56 brick decoration.jpg574.6 KB · Views: 331 -

57 two brick patterns.jpg655.9 KB · Views: 335

57 two brick patterns.jpg655.9 KB · Views: 335 -

58 back view.jpg816 KB · Views: 327

58 back view.jpg816 KB · Views: 327 -

58 back view.jpg816 KB · Views: 333

58 back view.jpg816 KB · Views: 333 -

59 English Garden bond.jpg712.2 KB · Views: 358

59 English Garden bond.jpg712.2 KB · Views: 358 -

60 finished product.jpg679 KB · Views: 1,808

60 finished product.jpg679 KB · Views: 1,808 -

61 finished product 2.jpg697.1 KB · Views: 2,420

61 finished product 2.jpg697.1 KB · Views: 2,420 -

smoker chimney.jpg1.3 MB · Views: 1,967

smoker chimney.jpg1.3 MB · Views: 1,967 -

IMG_1226.jpg594.3 KB · Views: 1,817

IMG_1226.jpg594.3 KB · Views: 1,817

Last edited: