offset1945

Newbie

- Aug 5, 2016

- 28

- 18

Tfrank778,

This forum is great, you will learn everything you ever need to know to become a true Pit Master ... but ... as I am learning, it is all not in one easy to follow recipe. Not everyone is the same, many have completely unique smokers, etc.

One thing I see here in reading along is that you've not mentioned exactly how to run your fire. SmokinAl responded to me in a thread and gave me advice that changed everything for me: split sizes. To some perhaps his information was obvious, for me it was a game changer.

Before the splits sizes ........

If you have some time, just a few hours, it would be great if you could post to different graphs after having done the following:

The above two controlled tests will give you and the forum a much better idea of your draw AND importantly will for now leave out the huge variable of fire management.

btw ... regarding the door, MANY custom pit fabricators, whose pits are used by the best houses do not even have vents in the door.

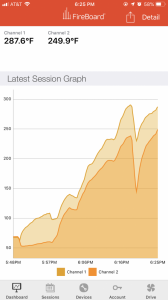

I can run a near perfect temperature graph by not being a slave to thinking that the door must be closed.

( I truly used to be mad about it, in my mind I would insist that I should be able to close the door )

Now, I run any combination of the door closed / vents closed / vents open / door wide open / door just cracked open etc etc

Do I burn slightly more wood?

Maybe, but if our objective is an even cook for 8 plus hours, with a graph that is a nice straight line .....................

This forum is great, you will learn everything you ever need to know to become a true Pit Master ... but ... as I am learning, it is all not in one easy to follow recipe. Not everyone is the same, many have completely unique smokers, etc.

One thing I see here in reading along is that you've not mentioned exactly how to run your fire. SmokinAl responded to me in a thread and gave me advice that changed everything for me: split sizes. To some perhaps his information was obvious, for me it was a game changer.

Before the splits sizes ........

If you have some time, just a few hours, it would be great if you could post to different graphs after having done the following:

- Remove all tunning plates, remove the stack extension, leave grates

- Stage your probes

- Count out exactly 60 very nice/pretty quaily charcoal briquettes

- Light them in a chimney starter or directly in your FB, make sure they are in a nice concentrated pile

- Run this test, stack wide open and all FB vents wide open

The above two controlled tests will give you and the forum a much better idea of your draw AND importantly will for now leave out the huge variable of fire management.

btw ... regarding the door, MANY custom pit fabricators, whose pits are used by the best houses do not even have vents in the door.

I can run a near perfect temperature graph by not being a slave to thinking that the door must be closed.

( I truly used to be mad about it, in my mind I would insist that I should be able to close the door )

Now, I run any combination of the door closed / vents closed / vents open / door wide open / door just cracked open etc etc

Do I burn slightly more wood?

Maybe, but if our objective is an even cook for 8 plus hours, with a graph that is a nice straight line .....................

Last edited: