Well, time for an update. Got a few things done while freezing my toes off. Got a propane tank holder in place. As suggested, I think I'll build another one to match.

Had to make sure the hose was the right length and flowed properly...

Lunch break.....

The counter weights were bugging me so I cut them off and glued on a new set. The old ones were @ 76 lbs. The new ones weigh in @ 97 lbs. I also changed the geometry a little. The doors now open easily with one hand and bottom out against the back of the tank when open. It sucked spending all the extra time and material on this step, but it was well worth it. Oh well; trial and error. Only took two times to get this one right.

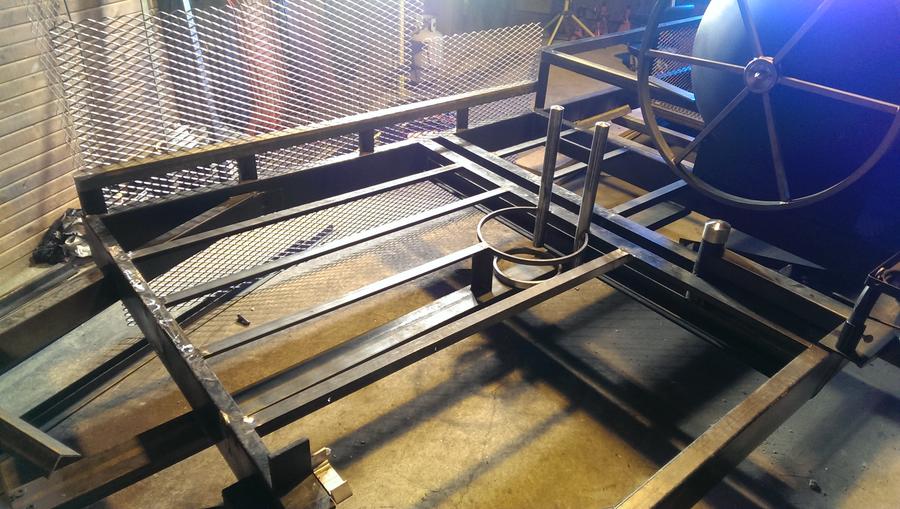

Got the frame work in place for wood storage. Ordered up some expanded steel and a set of fenders. Looking for a Knaack storage box if anyone happens to know where I can find one.

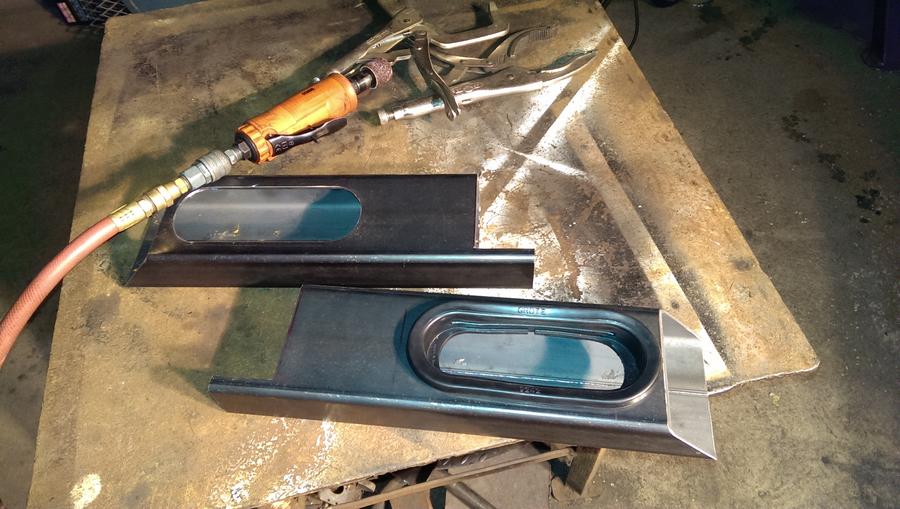

Started to work on some door latches. Spun up some H.D. bushing stock, reamed then fitted with 3/4" SHC. Top and bottom are welded solid to the bolt. I put a .008 two piece brass shim in place before welding; then removed afterwards. This gave it a little play for smooth turning. Cross drilled and tapped for grease zerks.

I then faced off the back to gain a smooth flat surface to weld the back catch to.

Started to turn some handles using 3/4" stainless square stock.

Then fitted some spring stock to them. Once everything looked good they were welded to the handles using 3330 alloy.

I did have to tweak the doors a touch. Figured I would get this out of the way before shoving a hole saw through for my door latches. And yes, this works.

While trying to figure out what to do with the end cap off of this tank, my drunk buddy (yup, him again) suggests turning into a fire pit since its so cold out. Sounds good...

Just some square stock and a few rounds for feet...

Not finished yet, but getting closer. I so feel like cooking a chicken right now...But its minus 5 out, 2:30 in the morning, I'm frozen, and....zzzzzzzzzzzzz...

![IMAG0255[1].jpg](/media/imag0255-1-jpg.298469/full?d=1507227927)