- Jan 1, 2022

- 9

- 4

Hello,

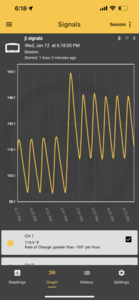

I just converted my Weber Smokey Mountain to electric. I have an old Ranco controller that I used for home brewing (max 220F). Right now I only plan to use for sausage, so that shouldnt be an issue. Is it typical for electric smokers to cycle this widely? The controller is set to a 1 degree differential. It’s an empty smoker, so I assume meat will add thermal mass. Should I insulate smoker? Outside temp is 35F. I started at 100F then bumped to 125F.

TIA

I just converted my Weber Smokey Mountain to electric. I have an old Ranco controller that I used for home brewing (max 220F). Right now I only plan to use for sausage, so that shouldnt be an issue. Is it typical for electric smokers to cycle this widely? The controller is set to a 1 degree differential. It’s an empty smoker, so I assume meat will add thermal mass. Should I insulate smoker? Outside temp is 35F. I started at 100F then bumped to 125F.

TIA