Hey Pop's, what do you recall about your dad smoking with corn cobs?

- Thread starter shortend

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Well, i posted my latest debacle in another post, so now I can continue with this one. I'm at home and recuperating. Gotta be in short spurts cuz I tire out easy. So, where was I?

michael ark

Master of the Pit

The cobs we used were dried and taken to the grist mill to be ground into marble sized chunks. We got them from the grist mill (GLF) in 100# burlap bags (we'd get a few 50# too, but not many; those were for when only the women were there and had to bring up a bag or two) and one of the most important things was to make sure the bags stayed dry, otherwise they could spontaneously combust if left touching each other. As long as they were dry you could store them down cellar; in the cob room we usually had 30 - 40 bags stored. Esp. during winter and custom slaughtering season we'd got through a couple bags a day running both smokehouses 10 hours or more.

Then, the local grist mill closed down and we had to drive to one outside of Syracuse, called Mercer Mills. That was a haul and trying to bring back as many bags as possible was difficult. Then, not long after, farmers started not shelling their corn in the field and hauling off the cobs separately; we had to pay farmers to do so because they could send their corn to the BirdsEye plant and get it shelled and processed there at a good price. Eventually we had to no longer use plain corn cobs because they just weren't available; we had to use low moisture ensilage (corn and cob together used for feed) and it was excessively dangerous, a/c trying to bag and store it prompted constant worry on spontaneous combustion. Eventually the use of dried corn cobs could not be provided locally. Dad had passed away and mom was wanting to retire and refused to sell the business to any of us kids (she said she'd never forgive herself for strapping us with a 7 day a week business) and sold it outright to a business wanting to start a chain. The new owner bought up a couple other properties, tore down the old store and there is now a modern grocery chain store there.

Then, the local grist mill closed down and we had to drive to one outside of Syracuse, called Mercer Mills. That was a haul and trying to bring back as many bags as possible was difficult. Then, not long after, farmers started not shelling their corn in the field and hauling off the cobs separately; we had to pay farmers to do so because they could send their corn to the BirdsEye plant and get it shelled and processed there at a good price. Eventually we had to no longer use plain corn cobs because they just weren't available; we had to use low moisture ensilage (corn and cob together used for feed) and it was excessively dangerous, a/c trying to bag and store it prompted constant worry on spontaneous combustion. Eventually the use of dried corn cobs could not be provided locally. Dad had passed away and mom was wanting to retire and refused to sell the business to any of us kids (she said she'd never forgive herself for strapping us with a 7 day a week business) and sold it outright to a business wanting to start a chain. The new owner bought up a couple other properties, tore down the old store and there is now a modern grocery chain store there.

So, the heyday of using corncobs for a smoking medium is past unless you have a source locally for it. With the remnants of corn sugar, they burn well but not as hot as ensilage does with the corn in it, they have a sweeter smoke than hardwood, and they smolder well. If they're wormy, it just adds to the flavor, lol!

We'd get our fresh hams from Tobin Packing Co. in Rochester in batches of 36 hams at a time, 12-14 lb. raw weight per. They (normally) would be pretrimmed with the hocks cut off. We would unpack them, then get out the pickle pump and pump them, injecting each 7 or more times in specific areas so they would be thoroughly pumped (see my ham thread below to find out how and where), then toss into barrels (55 gal. drums - 2), cover with brine and weighted down with 5 gal. water jugs partially filled. Then roll them into the brine cooler and record the barrel information, date, etc. on a big chart we would make up.

21-30 days later we would rotate the product through and out of the brine cooler to prepare for the smokehouse, emptying the barrels with a long hand hook to a meat truck that we'd roll out to the meatroom where we'd sack each ham from a huge roll of stockinette.

Dad had two rows of smoke sticks three deep. You would sack each ham in stockinette and tie the square knots so that the ham would hang on the ham hook the thinnest so you could fit 6 hams on a stick. Three rows deep of hams 6 each by two rows high, total of 36 hams to a smokehouse.

You would start the smokehouse approx. 7 am, feeding cobs every half hour into the pan, pulling it out to fill then pushing back in over the propane flame to let smolder. The hams smoked the first day to 6 pm, the thermostat set to a constant temp of 145° - 150° until the hams reached an internal of 135°. Some hams, as long as they were 135° or greater, were pulled then and hung for 'uncooked hams'. The temp was lowered to 130° overnight. The next morning the temp was raised to 160° and continued to cook with no more smoke until temp internal was a minimum 146°, then these were pulled as 'fully cooked' hams. (They were all pulled and hung into a separate drip cooler):

bellies, uncooked hams, cooked hams hanging in the drip cooler.

On the bellies, we would get the bellies from Pilgrim Packing in Syracuse in 350 lb. batches. We would put down the bellies in 55 gal drums, 2 of them, laying them flat and rotating them, sometimes putting two small ones side by side, either skin up or skin down, didn't matter. We'd cover them with brine and weight them down with 5 gal. collapsable water bags partially filled to keep the product submerged and roll them into the brine cooler, again recording the barrel no's and dates on our big chart to let sit and cure for 21 - 30 days.

We'd rotate product through the brine cooler sometimes several times a week depending on business, but we always smoked at least a minimum of 350 lbs of bellies and 36 hams a week for sale, and most weeks two or three more batches.

Of course, we always had side products to do too - hocks, ears, snouts, tails, chickens, turkeys, dried beef, corned beef to pickle, sometimes pastrami to smoke, beef plates for beef bacon, whole smoked beef livers, smoked tongues, Canadian bacon, you name it if it moved at one time we probably smoked it!

We'd get our fresh hams from Tobin Packing Co. in Rochester in batches of 36 hams at a time, 12-14 lb. raw weight per. They (normally) would be pretrimmed with the hocks cut off. We would unpack them, then get out the pickle pump and pump them, injecting each 7 or more times in specific areas so they would be thoroughly pumped (see my ham thread below to find out how and where), then toss into barrels (55 gal. drums - 2), cover with brine and weighted down with 5 gal. water jugs partially filled. Then roll them into the brine cooler and record the barrel information, date, etc. on a big chart we would make up.

21-30 days later we would rotate the product through and out of the brine cooler to prepare for the smokehouse, emptying the barrels with a long hand hook to a meat truck that we'd roll out to the meatroom where we'd sack each ham from a huge roll of stockinette.

Dad had two rows of smoke sticks three deep. You would sack each ham in stockinette and tie the square knots so that the ham would hang on the ham hook the thinnest so you could fit 6 hams on a stick. Three rows deep of hams 6 each by two rows high, total of 36 hams to a smokehouse.

You would start the smokehouse approx. 7 am, feeding cobs every half hour into the pan, pulling it out to fill then pushing back in over the propane flame to let smolder. The hams smoked the first day to 6 pm, the thermostat set to a constant temp of 145° - 150° until the hams reached an internal of 135°. Some hams, as long as they were 135° or greater, were pulled then and hung for 'uncooked hams'. The temp was lowered to 130° overnight. The next morning the temp was raised to 160° and continued to cook with no more smoke until temp internal was a minimum 146°, then these were pulled as 'fully cooked' hams. (They were all pulled and hung into a separate drip cooler):

bellies, uncooked hams, cooked hams hanging in the drip cooler.

On the bellies, we would get the bellies from Pilgrim Packing in Syracuse in 350 lb. batches. We would put down the bellies in 55 gal drums, 2 of them, laying them flat and rotating them, sometimes putting two small ones side by side, either skin up or skin down, didn't matter. We'd cover them with brine and weight them down with 5 gal. collapsable water bags partially filled to keep the product submerged and roll them into the brine cooler, again recording the barrel no's and dates on our big chart to let sit and cure for 21 - 30 days.

We'd rotate product through the brine cooler sometimes several times a week depending on business, but we always smoked at least a minimum of 350 lbs of bellies and 36 hams a week for sale, and most weeks two or three more batches.

Of course, we always had side products to do too - hocks, ears, snouts, tails, chickens, turkeys, dried beef, corned beef to pickle, sometimes pastrami to smoke, beef plates for beef bacon, whole smoked beef livers, smoked tongues, Canadian bacon, you name it if it moved at one time we probably smoked it!

Thanks, Pops! That was another extremely interesting post. Ahhh, the good old days.....when ya worked your rump off! Living in Iowa and having friends and family still in farming, I can get all the corn cobs I could use. I may get ahold of some cobs, dry 'em out good, chop 'em up and give 'em a try on some bacon. Sounds like I'll need more of a white cob, like popcorn. Sweet corn would probably be too wet to get dried out good enough without spoiling. Field corn cobs are red, and I could probably mix a few of them in. I may have a project brewing.

Glad to see your doing OK. Keep up the good recovery, and thanks again.

ShortEnd

Glad to see your doing OK. Keep up the good recovery, and thanks again.

ShortEnd

I'd love to see you give it a go; don't know if you could do it commercially enough to make a business out of it but for a cottage industry it would be great to see someone still producing cob smoked hams again!

Definately not looking to do it commercially, but would like to try it on some bacon first. Then, maybe go for a ham. I've never cured a fresh ham before, but with your brine, I think may have to give 'er a whirl. Got some cobs lined up already. Corn harvest will be starting here, very soon. Haven't located the popcorn cobs yet, but will ask around. Several folks I know, grow a few acres of popcorn every year for a local popcorn company just a little south of here.I'd love to see you give it a go; don't know if you could do it commercially enough to make a business out of it but for a cottage industry it would be great to see someone still producing cob smoked hams again!

When I get ready, I'll give ya a holler for a little advice, if that's ok.

ShortEnd

The link at the bottom of my post tells how to pump a ham. Don't know about popcorn cobs, you may have quite the lively bunch of cobs smouldering, lol! As far as I know it was just field or sweet corn for feed that they used.

Definately not looking to do it commercially, but would like to try it on some bacon first. Then, maybe go for a ham. I've never cured a fresh ham before, but with your brine, I think may have to give 'er a whirl. Got some cobs lined up already. Corn harvest will be starting here, very soon. Haven't located the popcorn cobs yet, but will ask around. Several folks I know, grow a few acres of popcorn every year for a local popcorn company just a little south of here.

When I get ready, I'll give ya a holler for a little advice, if that's ok.

ShortEnd

jc1947

Smoking Fanatic

Pops,

Ya gotta get better soon. Where else are all us newbies going to hear stories like yours???

Or learn about cuts of meat no longer in the stores.

Hope your back to your old self soon,

JC 1947

Ya gotta get better soon. Where else are all us newbies going to hear stories like yours???

Or learn about cuts of meat no longer in the stores.

Hope your back to your old self soon,

JC 1947

Well, thank you, JC1947!

After some recent pm's on this, something's brewing in corncobland, so be in the lookout for more info coming along!

After some recent pm's on this, something's brewing in corncobland, so be in the lookout for more info coming along!

Well, it's been almost a year since that stroke, had another one 10/16/11 too that further downgraded me, haven't had any more since. i'm totally disabled and on permanent disability, can no longer work any more. So, i have ore time for projects in between naps (have a lot of healing that requires a lot of sleep).

But, this weekend I had time to go through an old album and discovered some lost memories I'd like to share with y'all if I can!

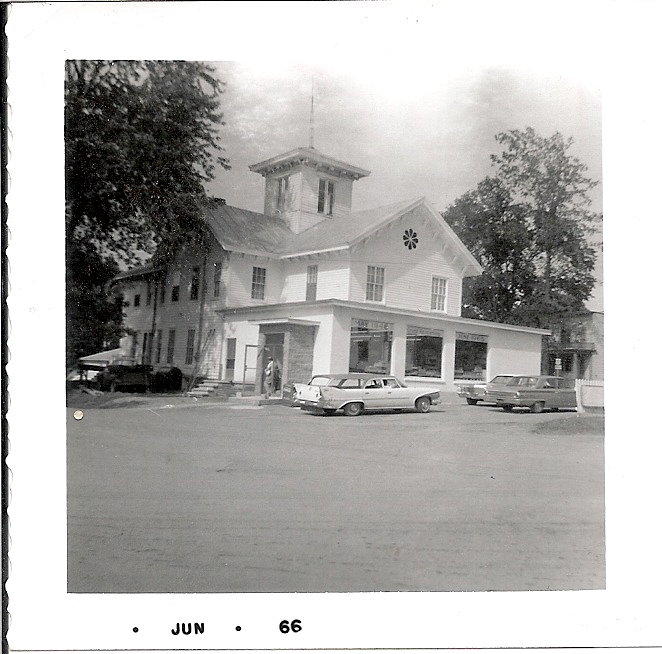

Pictures of the store after remodeling:

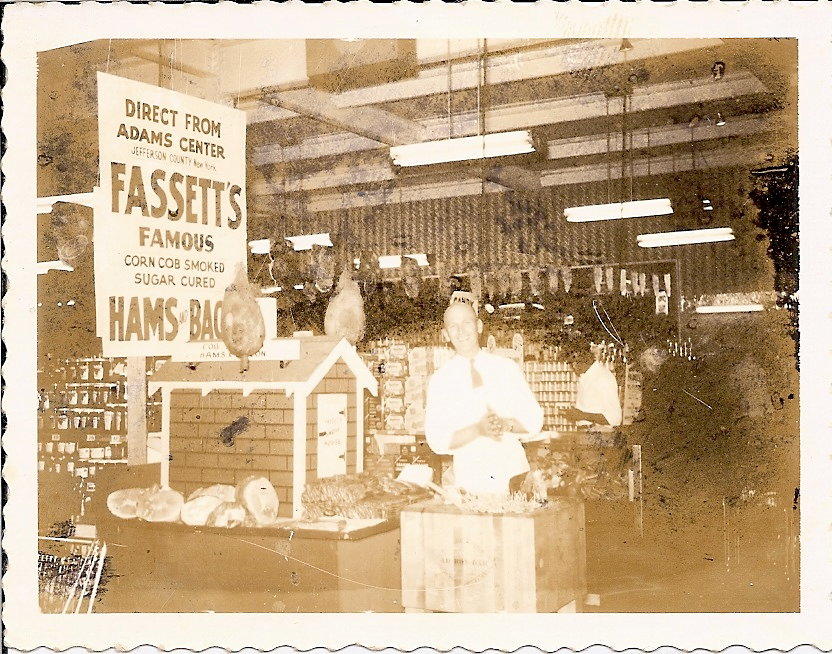

Dad at a farmer's market promoting his hams and bacons, around 1953.

inside the original store before remodel, around 1948. This was a new 'self-service' concept.

another shot, end displays, etc. Dad built and painted all the shelves and endcaps, there were no commercial fixtures!

But, this weekend I had time to go through an old album and discovered some lost memories I'd like to share with y'all if I can!

Pictures of the store after remodeling:

Dad at a farmer's market promoting his hams and bacons, around 1953.

inside the original store before remodel, around 1948. This was a new 'self-service' concept.

another shot, end displays, etc. Dad built and painted all the shelves and endcaps, there were no commercial fixtures!

Thanks for sharing the great memories Pops.... Find more pics if you can..... they are priceless.... Dave

Great pics Pops...

The pic of the outside brings back tons of memories.

We had a lot of fun times in that place.

I don't recall seeing you posting about the fire phone.

It was another job you did..I remember sitting the fire phone a few times that your whole family actually left the building.

Hahahaha I will be having a good day today thinking about you, John,Joann and your parents..

Have a great day yourself Pops...

The pic of the outside brings back tons of memories.

We had a lot of fun times in that place.

I don't recall seeing you posting about the fire phone.

It was another job you did..I remember sitting the fire phone a few times that your whole family actually left the building.

Hahahaha I will be having a good day today thinking about you, John,Joann and your parents..

Have a great day yourself Pops...

smokinhusker

Legendary Pitmaster

Thanks for sharing the pictures Pop's. I really enjoy a good blast to the past history and yours is quite rich indeed. I still haven't done that corn cob bacon smoke. I chopped up some of the dried cobs I had to do a test run to see how well they would burn. Had a little trouble keeping them going without getting the heat a little higher than I would like for bacon. Recently ordered some of Todd's Corn Cob pellets to give them a try. I know I'll be able to manage the temp with those. Again, thanks for the pictures. They're very interesting.

ShortEnd

ShortEnd

kadoka

Smoke Blower

dragonmaster194

Smoking Fanatic

Pops, Thank you so much for sharing the stories and pics. Keep it up, it brings back memories for me too. When I was a kid, we used cobs for heating our porch which had an old cook stove in it. My mom baked bread in it, and used cobs for the heat source. All my aunts and uncles were farmers and shelled their corn on the farm. Our family would go to visit family during this time and all the men would do the farm work and the women would cook. We would bring home a truck load of cobs and store them in the cellar. Every day during winter my chore was to bring a 5 gal bucket of cobs up to the cob bin in the porch. Now the farmers grind the coba as they combine the corn. Ah, the good olden days. Steve

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 19

- Views

- 2K

- Replies

- 14

- Views

- 2K

- Replies

- 37

- Views

- 3K

- Replies

- 26

- Views

- 3K

- Replies

- 23

- Views

- 2K

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Hot Threads

-

Featured First Smoked Chili

- Started by mneeley490

- Replies: 20

- Chili, Soups, and Stews

-

Not Sure What To Call It?!

- Started by Rafter H BBQ

- Replies: 14

- Blowing Smoke Around the Smoker.

-

Pop's Brine time for various meats and poultry

- Started by bilbo56

- Replies: 14

- General Discussion

-

First go on making bacon

- Started by Blue Collar Pit Boss

- Replies: 13

- Hot Smoked Bacon