Here's what I have so far.....suggestions

- Thread starter barlowds

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

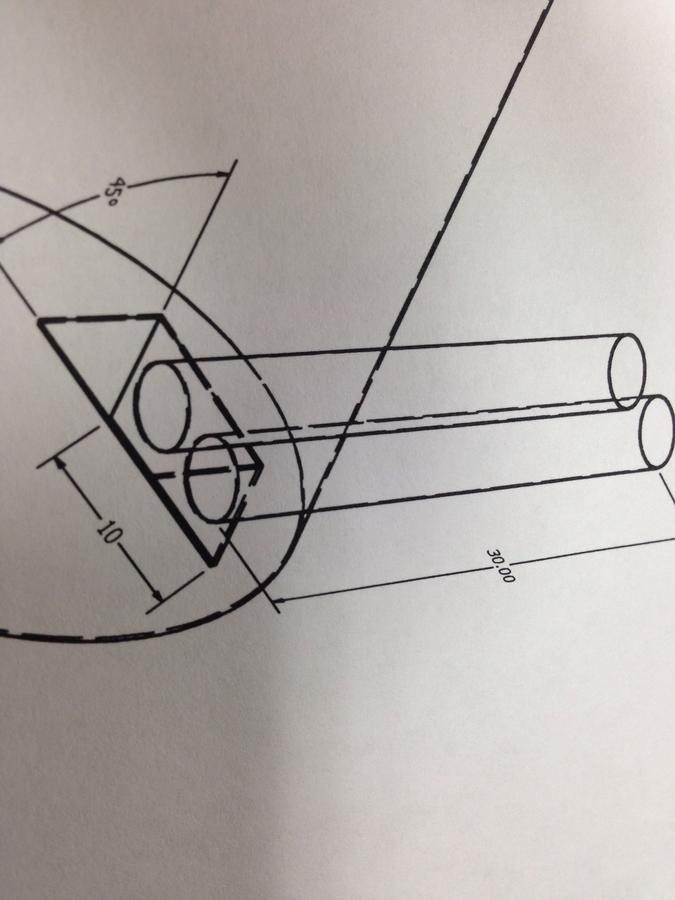

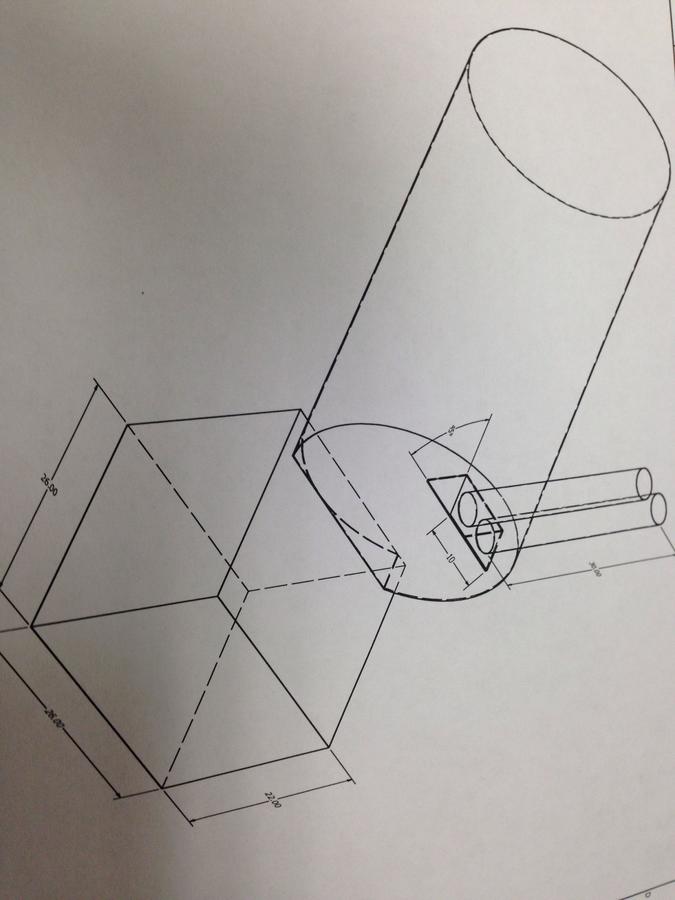

View media item 311053 am having trouble getting ahold of any 5" shimney pipe at a price I am willing to spend, but have lots of 4" around, I wanted to stay away from 4 because fenton says I would need to be 60" tall. here is a question for the engineers here with drag and all that jazz can I do two 30" stacks in a plenum off the end.

Link to BBQ Pit Calculator

I spent a good portion of the afternoon drawing it up in inventor and have all the measurments but cant figure out how to upload a pdf so I will atach a pic I took with my phone of the drawing

Link to BBQ Pit Calculator

I spent a good portion of the afternoon drawing it up in inventor and have all the measurments but cant figure out how to upload a pdf so I will atach a pic I took with my phone of the drawing

5" tube........ 5x5x.7854= 19.6 sq. in. area circ. 5x3.14159 = 15.7 " circ.

4" tube....... 4x4x.7854= 12.6 sq. in. area x 2 =25 sq. in. 4x3.14159 = 12.6 circ. x 2 = 25"

I would use 2 stacks the original height of 4"..... 25% more area and 60% more surface area for friction....

4" tube....... 4x4x.7854= 12.6 sq. in. area x 2 =25 sq. in. 4x3.14159 = 12.6 circ. x 2 = 25"

I would use 2 stacks the original height of 4"..... 25% more area and 60% more surface area for friction....

I did my test fire today, I would describe it as Mostly happy. It has nice flow, No problem getting up to temp but that is where the issue starts.

once I got it up to 250 I tried to shut it down to hold temp it kept climbing I could see that the fire box door had developed a warp and was letting in a lot of air. I hung out at 325 for about 80 min before it started to drop.

I have angle iron on the inside but not near the edge, you can see the warp in this pic. do you think I can just put in some gasket seal or I am open to other suggestions on how to fix the warp.

My next area of concern is the temp from one end to the other, on the left (non fire box) end my temp was 325. on the fire box end near the plenum and stack the temp would hang out around 260-270. My fire box temp (remember no seal on door) was around 500.

any ideas on how to even this out?

once I got it up to 250 I tried to shut it down to hold temp it kept climbing I could see that the fire box door had developed a warp and was letting in a lot of air. I hung out at 325 for about 80 min before it started to drop.

I have angle iron on the inside but not near the edge, you can see the warp in this pic. do you think I can just put in some gasket seal or I am open to other suggestions on how to fix the warp.

My next area of concern is the temp from one end to the other, on the left (non fire box) end my temp was 325. on the fire box end near the plenum and stack the temp would hang out around 260-270. My fire box temp (remember no seal on door) was around 500.

any ideas on how to even this out?

yes 10 gage, any suggestions on the heat differential on the two ends. I always kind of thought the fire box end would be the hotter end.

do you think getting a seal on that door will take care of the heat issue?

do you think getting a seal on that door will take care of the heat issue?

If you used the Feldon's numbers there are several issues...... What are the numbers you ended up using for ALL the numbers.....

http://feldoncentral.com/bbqcalculator.html?cc=30,60,0,0,0,0,42390.00,14130.00&fb=22,26,26,0,0,14872.00,14130.00,105.3&ch=4,743.60,59.20&fi=0,0,0,44.62,0&fc=12.31,17.40,118.98]Link

here is the link to my build numbers and I am very close on most things

fire box is 105% ,

opening between fire box and CC is 122 and they call for 119,

air inlet I have 44 they call for 44,

my reverse flow opening is 120.

I ended up using two 4" chimney stacks and using your suggestion earlier in this thread I went with 2, 4" pipe 37" long. they come out of a 10"x6" plenum pictured earlier in this thread

here is the link to my build numbers and I am very close on most things

fire box is 105% ,

opening between fire box and CC is 122 and they call for 119,

air inlet I have 44 they call for 44,

my reverse flow opening is 120.

I ended up using two 4" chimney stacks and using your suggestion earlier in this thread I went with 2, 4" pipe 37" long. they come out of a 10"x6" plenum pictured earlier in this thread

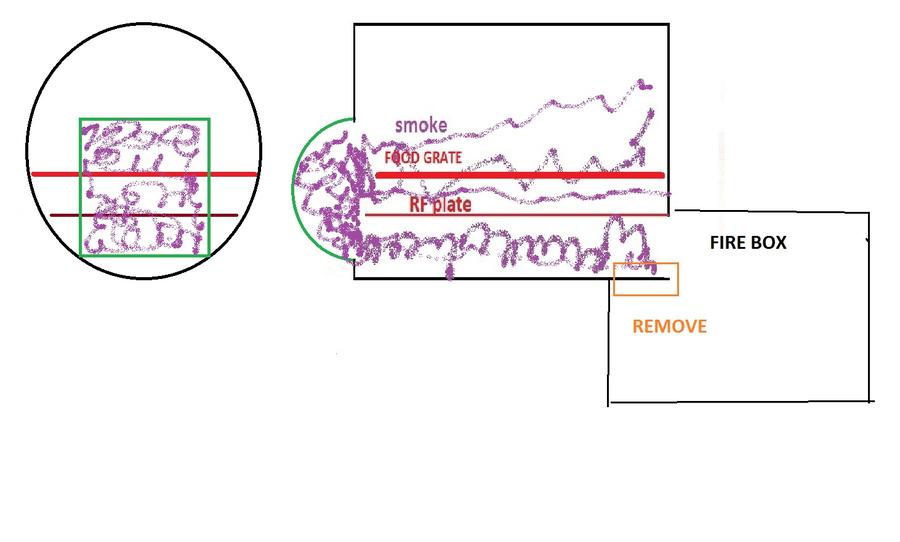

Using the Feldon's number for FB/CC opening and opening at the end of the RF plate, there very well could be a "choke" point at those two locations..... IMO Feldon's was designed for a SFB offset with tuning plates which allows for increased air flow due to it's "unrestrictive" design.... using those numbers for a Reverse Flow, overheating Fire Box has been somewhat the norm.... That could be "part' of the cause of your door warping... I recommend openings of 150% of Feldon's numbers for the FB/CC opening and the opening at the end of the RF plate and the area "UNDER" the RF plate to reduce friction and loss of air flow.... also, to help reduce heat in the FB, I recommend an additional air inlet to the FB above the fire to directly across from the FB/CC opening.... What that opening allows for is.......

The lower air inlet controls the heat output of the fire....... The upper air inlet allows for "moving the heat" from the FB through the CC to the exhaust... that helps to even out the temps in the smoker...... also help keep the FB cooler and reduces fuel consumption..... Many folks have found that to be the case, when using those build parameters..... If you choose to modify your smoker, we will help you with the easy way to tackle that task.... many folks have done the same, to make their smoker a better performing unit......

.... click on pics to enlarge......

The lower air inlet controls the heat output of the fire....... The upper air inlet allows for "moving the heat" from the FB through the CC to the exhaust... that helps to even out the temps in the smoker...... also help keep the FB cooler and reduces fuel consumption..... Many folks have found that to be the case, when using those build parameters..... If you choose to modify your smoker, we will help you with the easy way to tackle that task.... many folks have done the same, to make their smoker a better performing unit......

.... click on pics to enlarge......

Last edited:

this is the inside looking at my RF plate, you cant see it very well but there is a 4.5" gap to let the heat up. not sure how to make this bigger easily. suggestions?

as you can see on the side of my fire box I put in vents on the top, I saw something similar to this in a thread a few months ago and thought it would draw in cool air to fine tune the temp. I am going to build a new door so I could easily add a vent on that to help move air.

This is looking in the fire box, as you can see in the pic above the fire box sits 5" under the cook chamber, I left the cook chamber run long her so that I could enlarge my FB/CC opening if I had to but didn't want it too big to start since I was with in my numbers, I can cut this bottom portion of the CC out to enlarge this opening, Question is how much?

thanks

Doug

as you can see on the side of my fire box I put in vents on the top, I saw something similar to this in a thread a few months ago and thought it would draw in cool air to fine tune the temp. I am going to build a new door so I could easily add a vent on that to help move air.

This is looking in the fire box, as you can see in the pic above the fire box sits 5" under the cook chamber, I left the cook chamber run long her so that I could enlarge my FB/CC opening if I had to but didn't want it too big to start since I was with in my numbers, I can cut this bottom portion of the CC out to enlarge this opening, Question is how much?

thanks

Doug

It appears the CC extends into the FB.... You could cut off a portion of the CC to allow for a smooth transition of heat/smoke/air into the FB.... I would cut it all the way to the FB so there isn't a "dead zone" to trap heat..... and screw up the smooth air flow.....

Ribwizzard has a slick attachment to solve that problem at the end of the RF plate.....

Holy Cow...... did that FB get hot or what !!!!!! Discolored steel, like what you have, is welding temps... No wonder the door warped...

We will fix that problem....

Lastly, when you redo the door, put the upper and lower air inlet in it..... that should keep a cool air curtain between the door and fire... "maybe".... build the door out of 5/16 or 3/8.....

The FB should be much cooler..... I would guess around 350 if you were running the smoker at 250.... that's with everything done.... cut the CC, scoop in the end of the CC, and air inlets....

Ribwizzard has a slick attachment to solve that problem at the end of the RF plate.....

Holy Cow...... did that FB get hot or what !!!!!! Discolored steel, like what you have, is welding temps... No wonder the door warped...

We will fix that problem....

Lastly, when you redo the door, put the upper and lower air inlet in it..... that should keep a cool air curtain between the door and fire... "maybe".... build the door out of 5/16 or 3/8.....

The FB should be much cooler..... I would guess around 350 if you were running the smoker at 250.... that's with everything done.... cut the CC, scoop in the end of the CC, and air inlets....

Last edited:

Thanks I like the scoop idea I can fab that up pretty easy

When I get back from the lake on Tuesday I will fire up the torch

When I get back from the lake on Tuesday I will fire up the torch

I had a good cook learned a lot the temp was good and consistent. My cook times will be a bit longer than with my traeger

Just wanted to give kind of a final update on this build, as you can see the thinks cooks like a champ, just want to say thanks for all the help last spring. The modifications have it cooking very nice and the temp holds true. The only problem is that it only holds 15 pork butts, the event I was cooking for had 17 to cook so I had to break out the Traeger, but now we know the max order :-)

Last edited:

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 21

- Views

- 2K

- Replies

- 45

- Views

- 20K

- Replies

- 32

- Views

- 3K

- Replies

- 25

- Views

- 25K

- Replies

- 2

- Views

- 11K

- Replies

- 287

- Views

- 53K

Hot Threads

-

Local To Your Area Recipe Thread?!

- Started by Rafter H BBQ

- Replies: 24

- Blowing Smoke Around the Smoker.

-

Power Out for last 4 days...

- Started by sandyut

- Replies: 24

- Blowing Smoke Around the Smoker.

-

California Roll

- Started by Gonna Smoke

- Replies: 22

- ABT's and all things Appetizers

-

Piedmontese deal

- Started by Steve H

- Replies: 20

- Blowing Smoke Around the Smoker.