This is my first attempt at building a Charcoal Gravity Feed Smoker.

I did not want a full size unit, so I decided to build what I call a Table Top version.

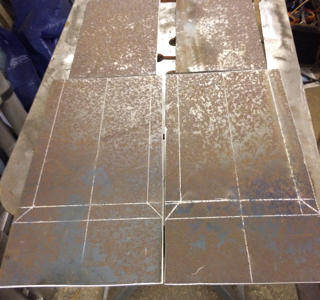

Started assembling the frame with the help of 90' clamps to keep things square.

Frame Built.

Had a good idea to line the inside with Stainless Steel, turned out to be the wrong decision as it twisted all over!

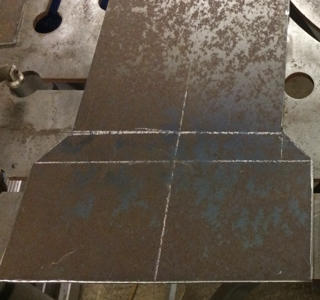

Fabricated the Charcoal Chute.

All welded together. 10mm Holes drilled to allow heat flow into main chamber.

Chute welded into frame.

Fire Chute connected to main chamber.

Stainless Steel Section added to put heat into the Centre of the chamber.

Stainless Steel Heat Deflector plate added.

Insulated added.

Outer skin applied.

Manufacturing Chimney with Butterfly valve.

Door Fitted using Bullet Hinges.

All Painted and Smokin Monkey Logo added.

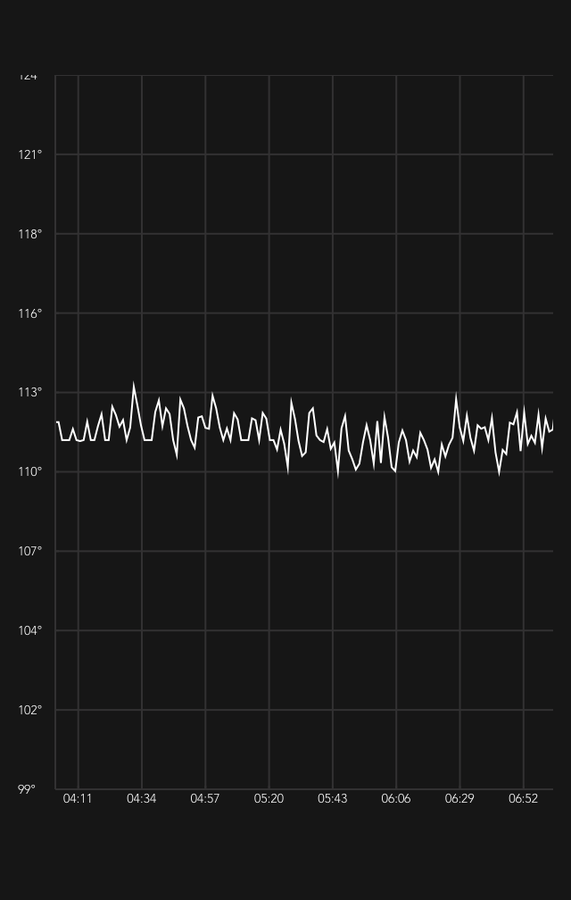

Using a Q Master Senior controller, and with this it runs with in 1'C.

I did not want a full size unit, so I decided to build what I call a Table Top version.

Started assembling the frame with the help of 90' clamps to keep things square.

Frame Built.

Had a good idea to line the inside with Stainless Steel, turned out to be the wrong decision as it twisted all over!

Fabricated the Charcoal Chute.

All welded together. 10mm Holes drilled to allow heat flow into main chamber.

Chute welded into frame.

Fire Chute connected to main chamber.

Stainless Steel Section added to put heat into the Centre of the chamber.

Stainless Steel Heat Deflector plate added.

Insulated added.

Outer skin applied.

Manufacturing Chimney with Butterfly valve.

Door Fitted using Bullet Hinges.

All Painted and Smokin Monkey Logo added.

Using a Q Master Senior controller, and with this it runs with in 1'C.

Last edited: