- Dec 23, 2013

- 56

- 13

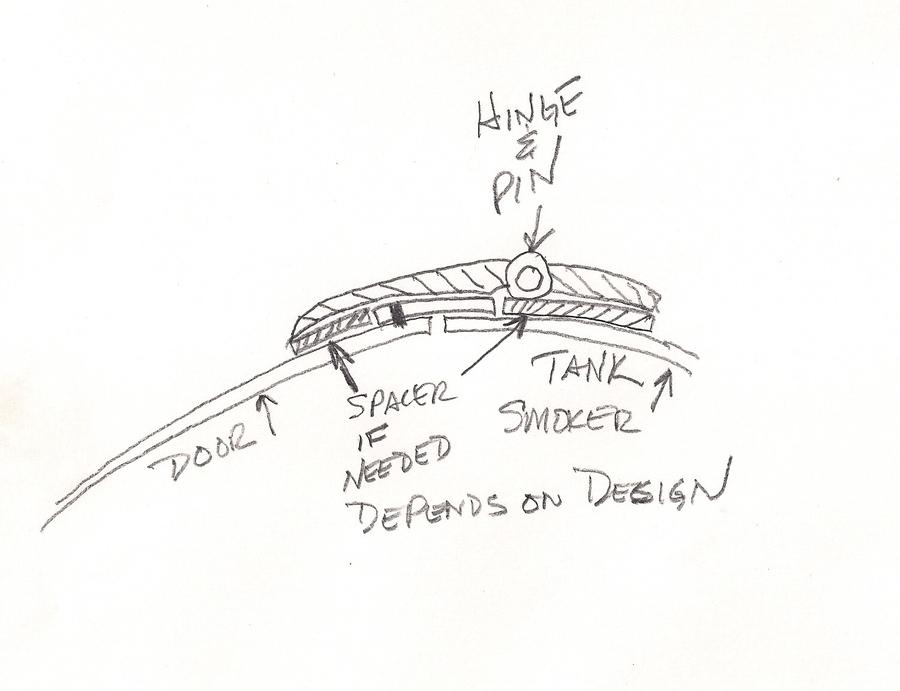

I may cut it open in the next few days, and get properly started! I just need to get some hinges made before I cut.

I have 5 wheels coming for it, all with ok tyres.

The axle is off a military trailer. Rated at 1500kg. All the brakes are like new, so I'm guessing it wasn't used much.

I'm not planning on going long distances, we cant go that far in the UK! I'm only planning on going maybe 30 miles max every couple of months.

Just had a thought, I could put something along the top to cover those bosses up. Like half piece of pipe lengthways.

.

Michael

I have 5 wheels coming for it, all with ok tyres.

The axle is off a military trailer. Rated at 1500kg. All the brakes are like new, so I'm guessing it wasn't used much.

I'm not planning on going long distances, we cant go that far in the UK! I'm only planning on going maybe 30 miles max every couple of months.

Just had a thought, I could put something along the top to cover those bosses up. Like half piece of pipe lengthways.

.

Michael