MikeFromTexas

Newbie

- Jan 11, 2020

- 7

- 5

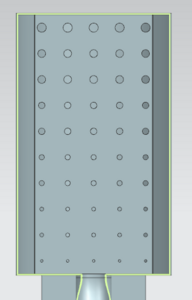

Finished my reverse flow build about 1 month ago. Not wanting to reveal my nerdy innards by performing a flow analysis through engineering software, I decided to follow the recommendations in this thread/tutorial. All I can say is that my pit is a great flowin machine. Great temperature control, temperature distribution and doesn’t seem to use that much fuel (about 12” log per hour).

specs:

45” cookin chamber

18” OD x 1/4 wall.

i’ll say this though, I spent a lot more money than I thought I would. Kinda like when I build ARs..

specs:

45” cookin chamber

18” OD x 1/4 wall.

i’ll say this though, I spent a lot more money than I thought I would. Kinda like when I build ARs..