- Jan 6, 2011

- 26,253

- 4,709

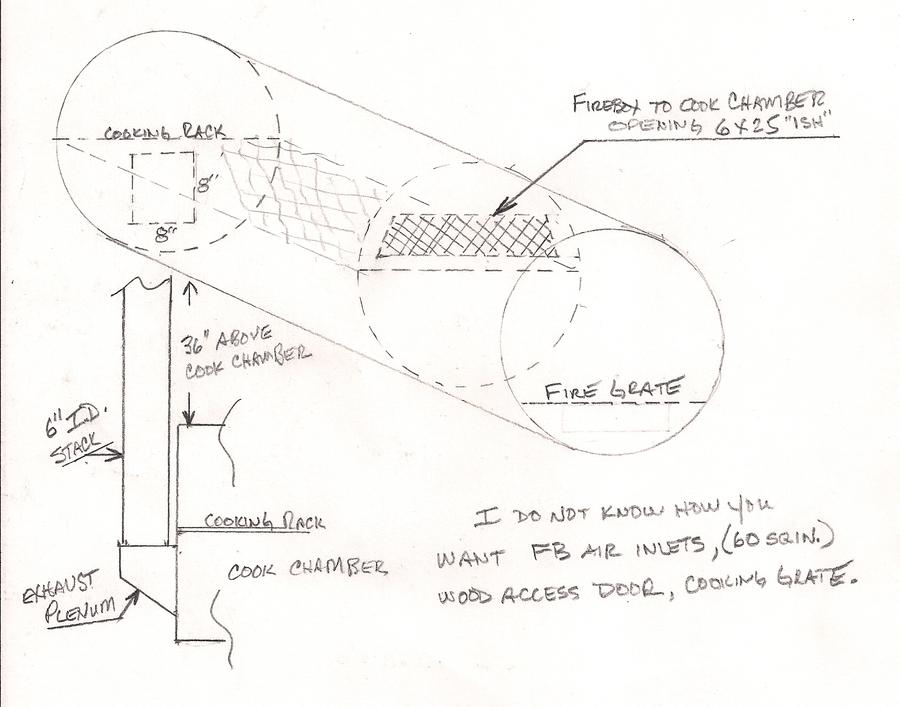

Hey Smokin Jo, here is what I come up with.

Feldon's has a few glitches when it comes to RF's The increased FB to CC opening size will result in much better heat, smoke and air flow. These figures come from trial and error.

My son and I build 1 to 2 pits a year during his slow time. These calculations work better than Feldon's .

Also: 33% of the CC for the FB is really the minimum you can take it on up to 35 -40 %.

Cook Firebox Stack FB to CC Firebox Firebox

Recommended Size Chamber 33% of CC Vol. Opening Opening (Low) Opening (High)

25,334 8,436 506.7 101.3 25.33 5.07

Gary

Feldon's has a few glitches when it comes to RF's The increased FB to CC opening size will result in much better heat, smoke and air flow. These figures come from trial and error.

My son and I build 1 to 2 pits a year during his slow time. These calculations work better than Feldon's .

Also: 33% of the CC for the FB is really the minimum you can take it on up to 35 -40 %.

Cook Firebox Stack FB to CC Firebox Firebox

Recommended Size Chamber 33% of CC Vol. Opening Opening (Low) Opening (High)

25,334 8,436 506.7 101.3 25.33 5.07

Gary