Alrighty now. First off apologies for the delay in getting back. It's Springtime in Central Texas and my dearly beloved has me busy as a one-legged man in an a$$ kicking contest getting the yard in shape. My passion is food, cooking, and cooking equipment. Hers is the yard. She supports my hobbies all year so I try to support her when she asks for help. The difference is that her supporting me never involved 11 straight hours of moving mulch all over 20 different plant beds covering almost 4 acres of land

That was yesterday and today was the first full cut/trim/edge/fertilize/weed & feed of the season. Oh joy....

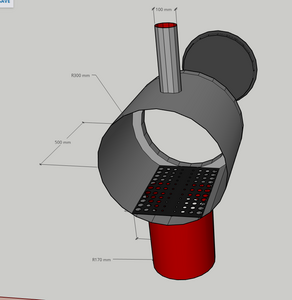

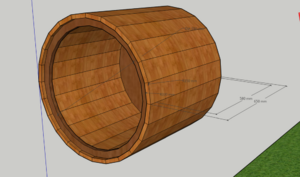

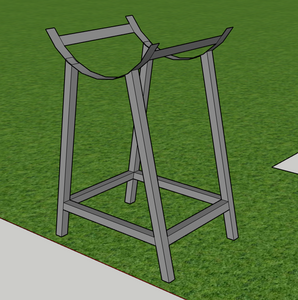

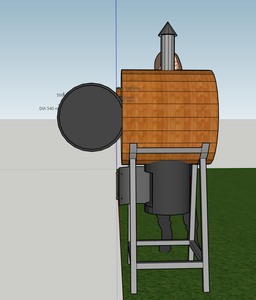

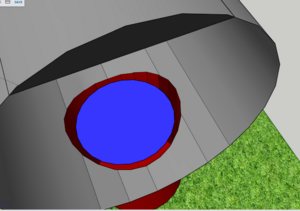

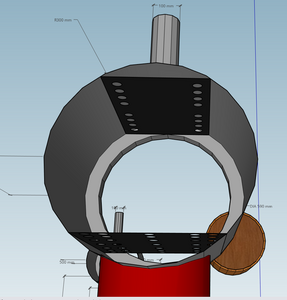

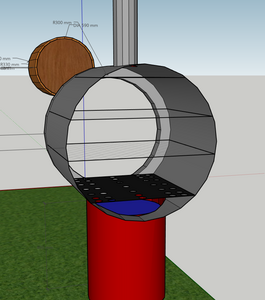

Now to the smoker. As stated, you're going to want to raise the main cooking grate to the center of the cook chamber as opposed to having it at the bottom as shown in the pic. In mine the heat deflector plate is two pieces of 8" round diameter 1/2' thick wall steel pipe that is cut lengthwise end to end. Total length of the two pieces is 4 to 5 inches shorter than the inside of the cook chamber. This is placed over the opening between the fire box and cook chamber. Based on your design you'll only need one piece but I have the double doors by my design. The deflector will create a reverse flow smoker that heats from both ends versus just one end in a standard reverse flow. This is a HUGE benefit insofar as even coking temps. You can either put it in the middle and have perfectly balanced temps end to end or you can move it for different temps at each end. Example: I regularly will put a brisket on one end and a few racks of ribs on the other end. I can slide the deflector plate, damp down one end and open the other, and have the smoker at 275 on one end for the briskets and 225 on the other end for ribs. You can also use it to adjust for a prevailing wind that may be blowing and throwing your temp balance off. There is a required number of square inches of opening between firebox and cook chamber based on the size of the cook chamber but I'm not certain what it is. I recommend making it a longer and narrower rectangle versus a square right in the middle. This will allow for better heat distribution to the cook chamber instead of just one very hot spot right in the middle.

I highly recommend setting it up with a smaller top cooking grate up higher to optimize your cooking capacity. This ideally will be about half way up between your main grate and the top of the smoker. Based on where this will sit, you'll want to move your vent stacks to the back of the cook chamber instead of directly in the center but the openings need to be higher than the upper grate. Doing this will put the vents (I do recommend doing two of them spaced about 4" apart) somewhere close to the middle of your upper grate. In this manner the upper grate will experience fully even cooking temps and smoke also as the heat and smoke are rising and exiting the cook chamber. The stacks should also be taller than what is indicated in the rendition you showed and you'll need rain caps/dampers on the tops of them.

When I had mine built and took delivery of it, after doing the burn in I did some major testing to see where the hot and cold spots are. I checked every possible combination of placements of the temp probes and was blown away at how evenly this smoker will maintain temps. The warmest spot was right in the middle above the firebox but only by a few degrees. Temps end to end and top to bottom were exactly the same and stayed within 2-3 degrees for hours at a time. Based on this, when I do a brisket I put the point toward the middle and the flat toward the end for even cooking. I don't get the flat over done and the point still needing time to get to temp.

Please feel free to fire away with any questions you may have. This smoker was my design and is virtually perfect. The only change I'd make if I was to have another one built would be to elongate the opening between firebox and cook chamber as described above. That is my take-away from this design/build experience. In all honesty, I don't think i'll ever need another one. I've owned probably 15 different smokers and this one is about as perfect as a person could ever ask for. Sort of a combination of all the good aspects from all the others rolled into one.

Did I miss anything?

Robert

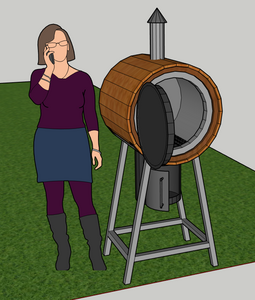

Woman for scale.

Woman for scale.

Woman for scale.

Woman for scale.