Hi everyone, i am new to the forum, I should have found this before!! So many things to read here..

So here is why i came for at first.. I have a bradley smoker, which i made a home made PID to control the temperature.

I have been running it with my actual setup for 2 years, and i finaly took time today to fix something that has been frustrating since day one, but never took time to fix it.

I don't know where in the settings i can find what i am looking for.

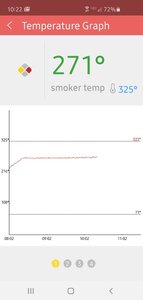

Right now, the temperature always go 7-10 degrees higher to 5-7 de grees lower. As when it reach the set temperature, the element are turned off, but the temperature still go up as the elements are still burning hot, and when it reach back the right temperature, by the time the element are heating at full capacity, it goes down by another 5-7 degrees.

So i always have 10-20 degrees off range in my smoker and i am almost sure i can fix that with my Inkbird ITC-106.

Like a quick on/off toggle so the temperature always stay at what it was set, 1-2 degrees off range.

So i came here wishing someone had an answer for me as i cannot find it anywhere else on the internet!

Thanks alot for you time :)

Hi there and welcome!

Dr k has you on the right track.

Your issue is that your PID needs a little tuning. Like Dr k says record your initial settings before you make any changes so u can get back to that configuration or you can get completely screwed lol.

Basically the turning works like this. Put I and D at 0 and tune P so that are overshooting and undershooting within the ballpark. Tune up I to ensure that when u are close to the set temp it fights to keep it from going too far either way. Tune up D to keep rates of change from getting too large so that you can tighten things up even more.

That's it in a nutshell but not always an easy thing to get rigth AND can be time consuming

Here's more detailed turning steps.

Basically to turn the P to like a 3 and turn the I and D to a 0.

Mess with the P until it the heating overshoot/undershoot is about as good as it is going to get and then u start dialing up the I and when that gets better if u still have room for improvement you dial up the D.

The way P works in detail is tjat a P value of lets say 5 behaves so that when u get to like 5 degrees below our set temp (lets say 250F) the power will start cutting down and will cut off when it hits the set temp.

So upon initial heat up it heats full blast then at 245F the power gets cut down, at 246, 247, etc. the power continues cutting down until 250F and the power is off BUT the electric heating element has been going so hard for so long that the temp is still rising so the smoker may go all the way up to like 265F until it cools down from having the power being off.

THEN the heat drops and when the temp gets to 249F the power cuts back up low and at 248, 247, etc. increases and at 244F it is on full blast again, BUT because the element has been off and cooling for so long your temp may dip down to like 235F before the element gets hot enough to start getting the smoker to heat up again and then the cycle repeats.

The spread will cut down some but will never fully dial in because P is dumb so you gotta tune where the higher the P value the slower the smoker comes up to temp and the response time changes so people say to keep it low and I would think starting with a value of like 3 would be good to go.

Get the P dialed in to where u have a good little cycle going.

You then start dialing up the I.

Now the purpose of I is so that as you approach the set temp of 250 it starts to fight output power from P so that your cycle around your set temp gets cut down.

So think of "I" as only kicking in when you near 250F. When you are heating up to 250 "I" cuts the power down quicker than P to try not to overshoot 250F by too much, and when the temp is dropping as it approaches 250F or goes under, "I" kicks the power on to heat it up faster and to reduce the drop portion of the cycle. "I" performs a calculation based off P so that it doesnt just override P but simply works to assist P without taking over.

Now the value for I simply depends on your controller as they all use different algorithms so reference the documentation or tweak based off the default numbers you had recorded before zeroing it out and then go higher or lower and see what happens.

Once you have cut down the overshoot and undershoot you will either be close and happy OR you move on to D.

D 's job is to watch temperature RATE change over time and if it notices rate changes going to fast or too slow it fights in the opposite direction to keep the temperature RATE changes from getting too out of whack by looking back on what the temp rate change was like every previous 30 sec and then acts accordingly.

D will help dial in your overshoot/undershoot even more to tighten near your set temp ... provided it's tuned correctly. Like "I", the D value will calculate with the P value so it can never completely override P.

Confusing enough for ya? :P

Ask all the questions you need as this stuff is not super simple but if you play with it about 3-4 sessions u will get an idea of the cause and effect of your tuning changes.

The WORSE thing you can do is just start changing numbers guessing what may happen. You simply have to start with P only where "I" and D are set to zero and then work from there... unless you like punishing yourself by doing things the really hard way hahaha.

Let us know what you get into :)