MES 40 gen 2.5 pid wiring

- Thread starter okiecat

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

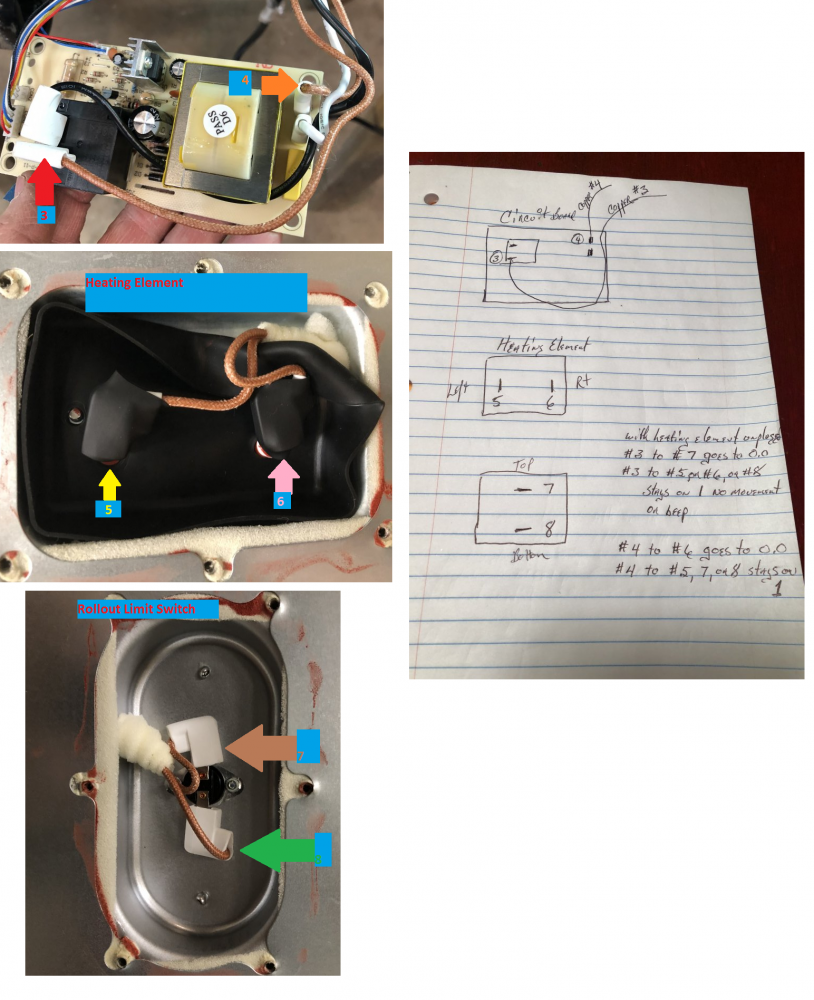

OK, so usually 0 readings (or really close to 0) indicates continuity.

I am going to make up a little "chart". I will fill in info from your notes and indicate tests/checks we need info on.

With wires unplugged from both the heating element and the circuit board we have the following:

Let's hold off on unplugging the wires/connectors from the rollout limit switch. It is a little delicate and we don't want to damage it or else it will heat up due to resistance and wreak havoc :)

If we get stuck though, then we will move to unhooking the limit switch :)

Please report back with what you find on the new checks and the double checks. Thanks!

I am going to make up a little "chart". I will fill in info from your notes and indicate tests/checks we need info on.

With wires unplugged from both the heating element and the circuit board we have the following:

- 3 to 7 = Continuity Established

- 4 to 6 = Continuity Established

- 8 to 5 = ? need checked (this is from limit switch to heating element)

- 8 to 6 = ? need checked (this is from limit switch to heating element)

- 3 to 8 = No Continuity, Please double check this one

- 3 to 5 = No Continuity, Please double check this one

- 3 to 6 = No Continuity, Please double check this one

Let's hold off on unplugging the wires/connectors from the rollout limit switch. It is a little delicate and we don't want to damage it or else it will heat up due to resistance and wreak havoc :)

If we get stuck though, then we will move to unhooking the limit switch :)

Please report back with what you find on the new checks and the double checks. Thanks!

3-7 ok

8-5

4-6 ok

Plenty of lead to work with for the four cut , two splice solution. That way you can leave enough wire to put it back if you want (leave a couple inches of wire on the connector side when cutting and leave the connectors where they are.) After all this tracing I'd label each end of the wire with a tag of the same number. First hot wire ends H1and H1. Second hot wire ends H2 and H2. Neutral wire ends N and N. After cutting the fiberglass wires to splice label each two inch pigtail from cutting the wire with the corresponding H1 and N so you know at a glance where they were originally terminated. The power cord wires can be paired up by color if you need to put it back.

8-5

4-6 ok

Plenty of lead to work with for the four cut , two splice solution. That way you can leave enough wire to put it back if you want (leave a couple inches of wire on the connector side when cutting and leave the connectors where they are.) After all this tracing I'd label each end of the wire with a tag of the same number. First hot wire ends H1and H1. Second hot wire ends H2 and H2. Neutral wire ends N and N. After cutting the fiberglass wires to splice label each two inch pigtail from cutting the wire with the corresponding H1 and N so you know at a glance where they were originally terminated. The power cord wires can be paired up by color if you need to put it back.

Last edited:

ok Waiting to get fire built in shop. Its cold here today, 18 and wind chill 3*. Also I have already unplugged rollout switch. They had a barb on the connector. Fortunately I had the correct pliers. Also when I touch my terminal ends together it goes to is on 1 and stays there. Going to take some more pics too.

Ok 3 to 7 is 00, 3 to all others is 1, 8 to 5 is 000, 8 to 6 is 1, 7 to 5 or 6 is 1 All terminals are unplugged,ok Waiting to get fire built in shop. Its cold here today, 18 and wind chill 3*. Also I have already unplugged rollout switch. They had a barb on the connector. Fortunately I had the correct pliers. Also when I touch my terminal ends together it goes to is on 1 and stays there. Going to take some more pics too.

Ok 3 to 7, 4 to 6, 5 to 8 All terminals accounted for. Which ones hot and which ones neutral?Ok 3 to 7 is 00, 3 to all others is 1, 8 to 5 is 000, 8 to 6 is 1, 7 to 5 or 6 is 1 All terminals are unplugged,

Wire 3-7 to snap disk is hot wire #1. Wire 8-5 from snap disk to heating element is hot wire #2. Wire 4-6 from other heating element leg is neutral.

Thanks Kurt, I kinda thought I had the 3-7 wire figured out. I want to say to all, especially Tallbm. Thanks for all the help and patience. I would not have started this project if not for Tallbm's original thread for the Gen 1 rewire.Wire 3-7 to snap disk is hot wire #1. Wire 8-5 from snap disk to heating element is hot wire #2. Wire 4-6 from other heating element leg is neutral.

Since Tallbm did all the Gen 1 no back removal continuity work it is easy to memorize for when I do my Gen 1. I got the PID down on programming etc. I just need a snow free warmer day to make four quick cuts and two wire nut splices then auto tune. When auto tuning for sou vide it's just the water bath so I'll just auto tune the smoker without a load inside the smoker. Just the standard setup inside.Thanks Kurt, I kinda thought I had the 3-7 wire figured out. I want to say to all, especially Tallbm. Thanks for all the help and patience. I would not have started this project if not for Tallbm's original thread for the Gen 1 rewire.

Ok 3 to 7, 4 to 6, 5 to 8 All terminals accounted for. Which ones hot and which ones neutral?

Wire 3-7 to snap disk is hot wire #1. Wire 8-5 from snap disk to heating element is hot wire #2. Wire 4-6 from other heating element leg is neutral.

Good work okiecat and Kurt. Looks like you guys got it all handled. I was kind of out of pocket all weekend and once I saw Kurt's answer I was happy to see it was resolved. I figured I would chime back in once I got some time... which is now :D

Thanks Kurt, I kinda thought I had the 3-7 wire figured out. I want to say to all, especially Tallbm. Thanks for all the help and patience. I would not have started this project if not for Tallbm's original thread for the Gen 1 rewire.

No problem. I'm glad I could help and I'm glad Kurt came to the rescue while I was out over the weekend.

I think you will be rocking and rolling for sure!

Just a heads up, the rollout limit switch tabs are kind of delicate so if they ended up with some wiggle in them then they MAY overheat and the plastic portion of the switch melt down on you. Generally it is a cheap part to replace but may drive you nuts if all of a sudden you see that you aren't hitting your set temp and your smoker temp control is acting funny. That would be the first place I would look... I've learned the hard way and burnt up 3 of those switches because of attaching stiff electrical connectors on the delicate tabs/switch. I have a new process for doing so that seems to be working out if you run into the issue :)

Since Tallbm did all the Gen 1 no back removal continuity work it is easy to memorize for when I do my Gen 1. I got the PID down on programming etc. I just need a snow free warmer day to make four quick cuts and two wire nut splices then auto tune. When auto tuning for sou vide it's just the water bath so I'll just auto tune the smoker without a load inside the smoker. Just the standard setup inside.

Kurt my friend you will be in heaven once you have it setup. It is so funny how awesome the MES becomes with a rewire + PID controller combined with the AMNPS. It is freaking awesome! :)

Since I have a window I'm going to miss the inside light bulb when going to the PID. I really like it for over night smokes.Good work okiecat and Kurt. Looks like you guys got it all handled. I was kind of out of pocket all weekend and once I saw Kurt's answer I was happy to see it was resolved. I figured I would chime back in once I got some time... which is now :D

No problem. I'm glad I could help and I'm glad Kurt came to the rescue while I was out over the weekend.

I think you will be rocking and rolling for sure!

Just a heads up, the rollout limit switch tabs are kind of delicate so if they ended up with some wiggle in them then they MAY overheat and the plastic portion of the switch melt down on you. Generally it is a cheap part to replace but may drive you nuts if all of a sudden you see that you aren't hitting your set temp and your smoker temp control is acting funny. That would be the first place I would look... I've learned the hard way and burnt up 3 of those switches because of attaching stiff electrical connectors on the delicate tabs/switch. I have a new process for doing so that seems to be working out if you run into the issue :)

Kurt my friend you will be in heaven once you have it setup. It is so funny how awesome the MES becomes with a rewire + PID controller combined with the AMNPS. It is freaking awesome! :)

Since I have a window I'm going to miss the inside light bulb when going to the PID. I really like it for over night smokes.

View attachment 353602

I never clean my window so the missing the light was not an issue hahahahaha but yeah that is one con to the rewire. I didn't bother trying to wire in the light but I'm sure it isn't an impossible task BUT you might have to put in another switch or something :)

Here is an image with #1 and #2 marked on it.

Hooking #1 to 3 and #2 to 4 should give you the rewire you need for a PID. Just be sure to check continuity from the plug back and splice points to the end points on the heating element and rollout limit switch.

Let us know how this turns out and if you have any other issues :)

Hooking #1 to 3 and #2 to 4 should give you the rewire you need for a PID. Just be sure to check continuity from the plug back and splice points to the end points on the heating element and rollout limit switch.

Let us know how this turns out and if you have any other issues :)

Ok. Just checked everything. I had it right. 1/3 and 2/4. Also unwind and ck continuity. 1 to left plug prong-00. Good. 2 to right plug prong—00 good. 3 to 7 000 good. 4 to6–00 good. This also checked out with wires connected back. What now

Right power prong to 6 should show continuity.

Left power prong to 5 should show continuity.

If this rings true then you should have power/juice running to the heating element.

Let me know if this continuity check passes.

Left power prong to 5 should show continuity.

If this rings true then you should have power/juice running to the heating element.

Let me know if this continuity check passes.

Just got back. ok Have continuity at plug. RT to 6 and Lt to 5 Do I plug it in see if it will come on? Like I said I don't like or do electrics very well. Thanks

Just got back. ok Have continuity at plug. RT to 6 and Lt to 5 Do I plug it in see if it will come on? Like I said I don't like or do electrics very well. Thanks

Looks like you have done the job properly if you have that continuity showing.

I would plug it into the wall directly and keep the door of the smoker open. No extension cords.

I would then would hold my hand close to the heating element to see that it starts heating up. I wouldn't touch it.

If you feel it is heating up then your wire job should be good to go for moving to the PID controller and auto-tuning!!!

Do I try to turn the unit on or is this direct current to the element. Last time I couldn't get switch board on.

Do I try to turn the unit on or is this direct current to the element. Last time I couldn't get switch board on.

Your rewire should have bypassed the current controller and circuit board so when you plug in, it is on. If plugged directly into an outlet it will suck power and never stop so don't do this other than when you are testing in this case.

After you confirm it is heating up when plugged directly in you can then hook it to the PID and plug the PID into the wall and it will control the power to the smoker at that point.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 1

- Views

- 3K

- Replies

- 6

- Views

- 3K

- Replies

- 14

- Views

- 6K

- Replies

- 5

- Views

- 2K

- Replies

- 9

- Views

- 5K

- Replies

- 12

- Views

- 4K

Hot Threads

-

Power Out for last 4 days...

- Started by sandyut

- Replies: 28

- Blowing Smoke Around the Smoker.

-

Local To Your Area Recipe Thread?!

- Started by Rafter H BBQ

- Replies: 24

- Blowing Smoke Around the Smoker.

-

Is my bacon bad? Please help

- Started by hooked on smoke

- Replies: 24

- Bacon

-

Christmas Plans

- Started by Gonna Smoke

- Replies: 19

- Blowing Smoke Around the Smoker.

-

New Goodwill pan . Tater tot hotdish ?

- Started by chopsaw

- Replies: 19

- General Discussion