Started this build almost a year and a half ago.

It is my own design that is still evolving as I think up more cool stuff to do.

Basically a square cook chamber with some strategically placed curved surfaces to smooth airflow and reduce turbulence.

It will be fully insulated.

Here is how it has come together so far:

The "Kit" consisted of 2 sheets of 1/4" cut to 20" widths, and a section of 12" dia pipe.

First cut. Sprung 2" which is a good illustration of the stresses in a piece of pipe.

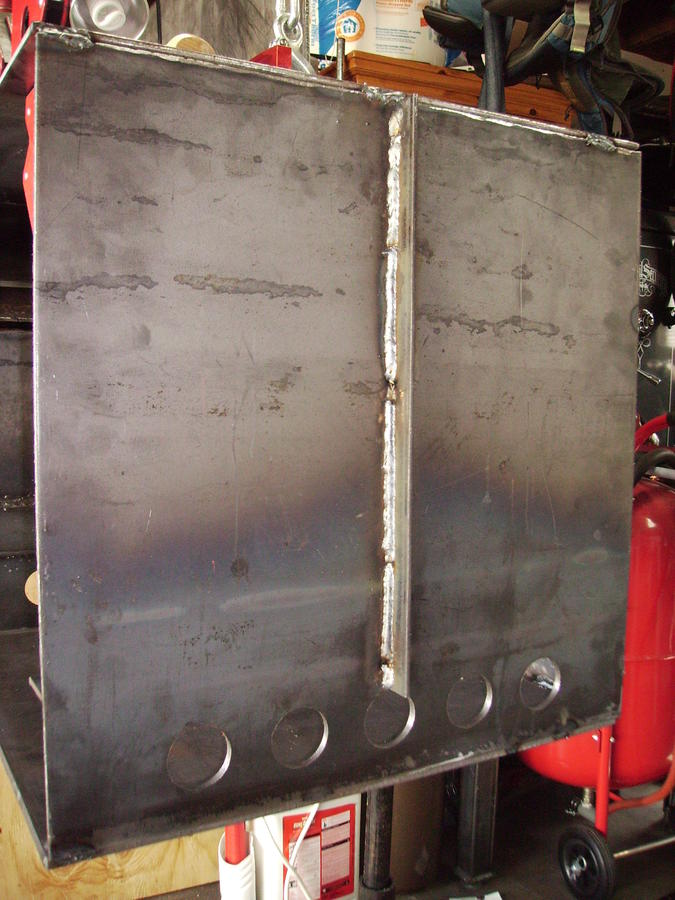

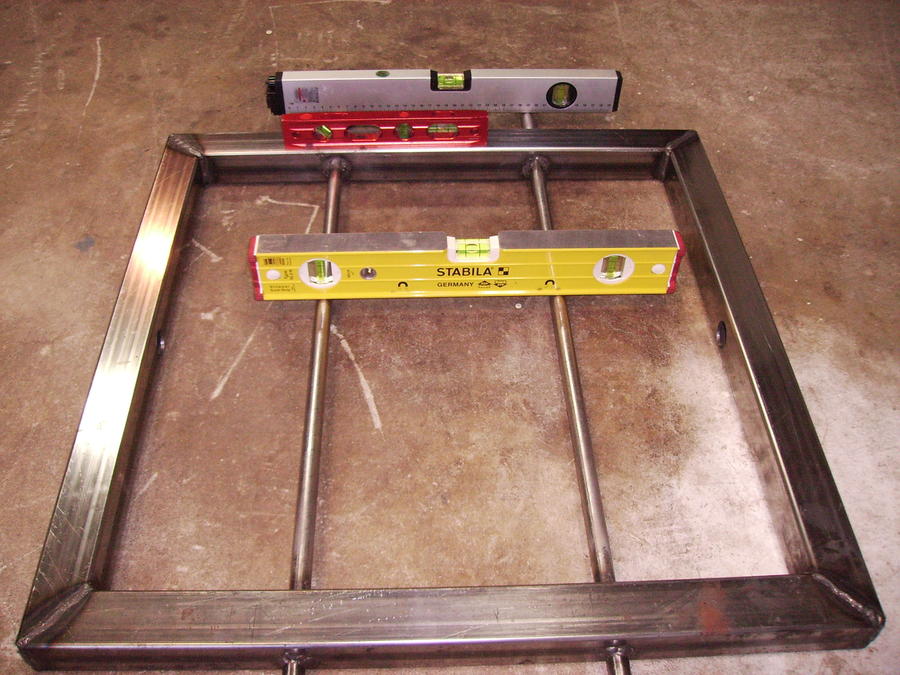

bottom of cook chamber

Built the tub.

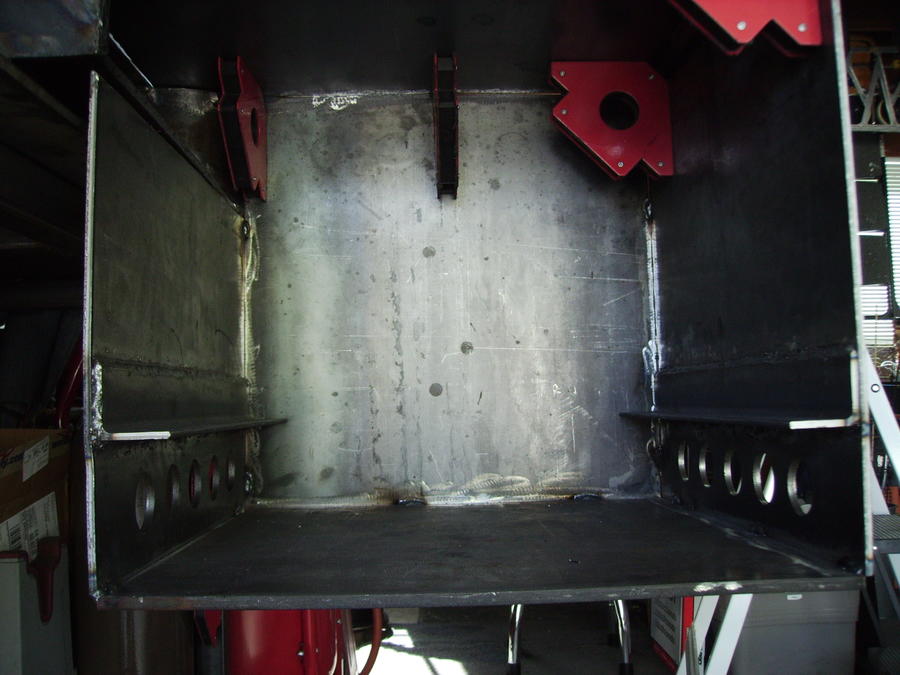

Installing the RF plate

RF plate has a 2 degree diagonal bend that places the left rear corner 1" low for grease drain.

Grease drain.

Clean-out drain

.

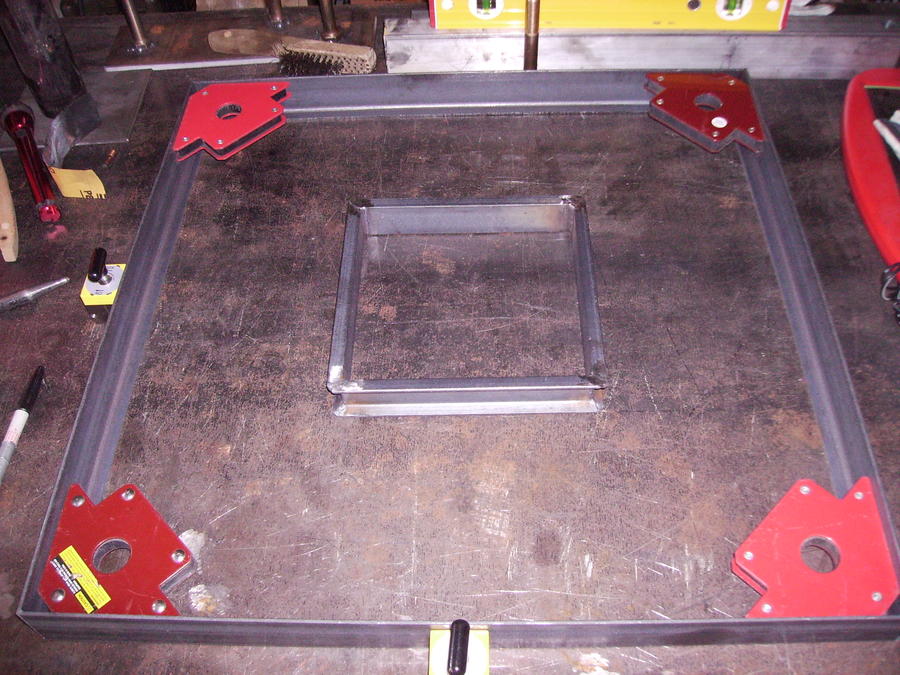

The Firebox tacked up. Got a piece of 3/8 for the floor.

Will add a sacrificial 1/4" plate to the top.

Strongbacks added to guard against warpage.

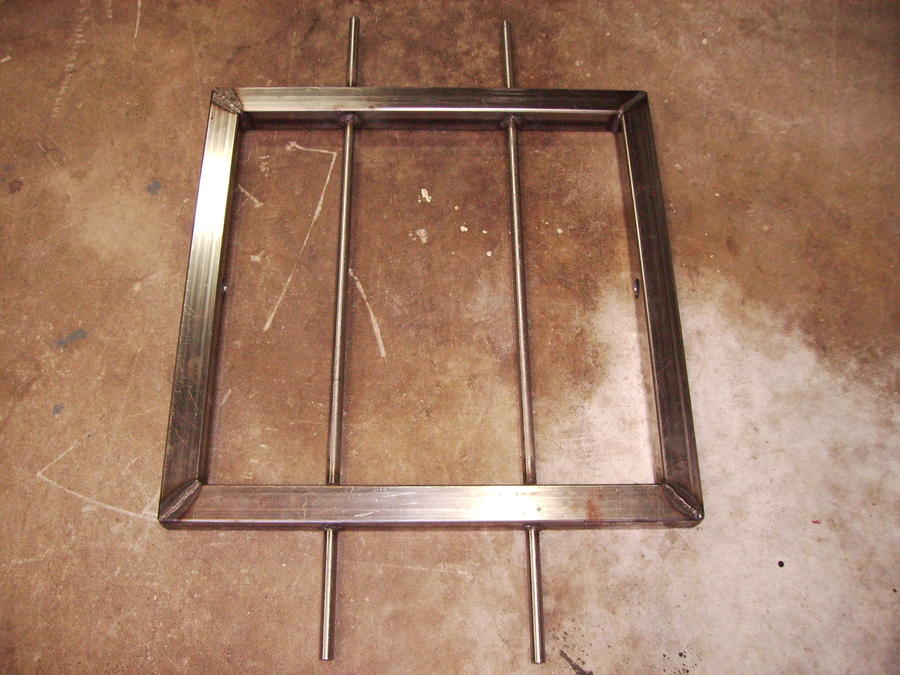

Been reading about Dave's secondary high air intake, and it is a intriguing concept.

May have to punch a couple holes in this side.

Fitting to the cook chamber

Lining it up

Tacked on.

Face for the door seal

Smoke stack

Chassis

where it is today

More to come....slowly

It is my own design that is still evolving as I think up more cool stuff to do.

Basically a square cook chamber with some strategically placed curved surfaces to smooth airflow and reduce turbulence.

It will be fully insulated.

Here is how it has come together so far:

The "Kit" consisted of 2 sheets of 1/4" cut to 20" widths, and a section of 12" dia pipe.

First cut. Sprung 2" which is a good illustration of the stresses in a piece of pipe.

bottom of cook chamber

Built the tub.

Installing the RF plate

RF plate has a 2 degree diagonal bend that places the left rear corner 1" low for grease drain.

Grease drain.

Clean-out drain

.

The Firebox tacked up. Got a piece of 3/8 for the floor.

Will add a sacrificial 1/4" plate to the top.

Strongbacks added to guard against warpage.

Been reading about Dave's secondary high air intake, and it is a intriguing concept.

May have to punch a couple holes in this side.

Fitting to the cook chamber

Lining it up

Tacked on.

Face for the door seal

Smoke stack

Chassis

where it is today

More to come....slowly