Thanks again, I got the Jest of the project. My connections look different, I will need to trace or continuity test the leads from the heating element. I have to go back and look at the specifics. I have 2 access points below my MES. 1 for the main electrical feed and another for a controller in the base of the unit. This second access panel is where I think I will find the Rollout Limit Switch & Heating Element. If so I may have to run some wires to make this connection, but I believe there should be existing wires/connections.

Guess I will order the PID tomorrow and keep you posted on the progress.

Regards,

James

You have correctly identified the 2 panels blow your MES.

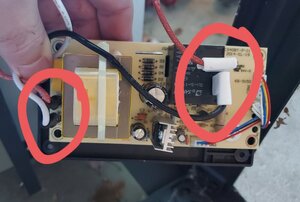

Yep, the panel that has the circuit board will have have all wires running to it.

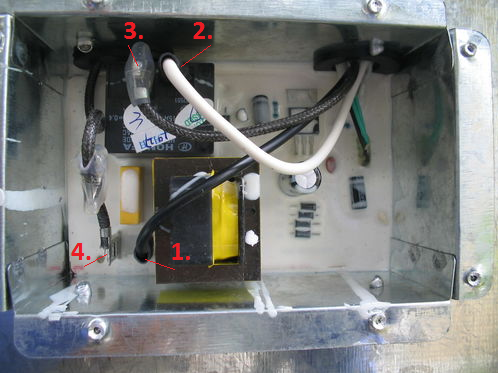

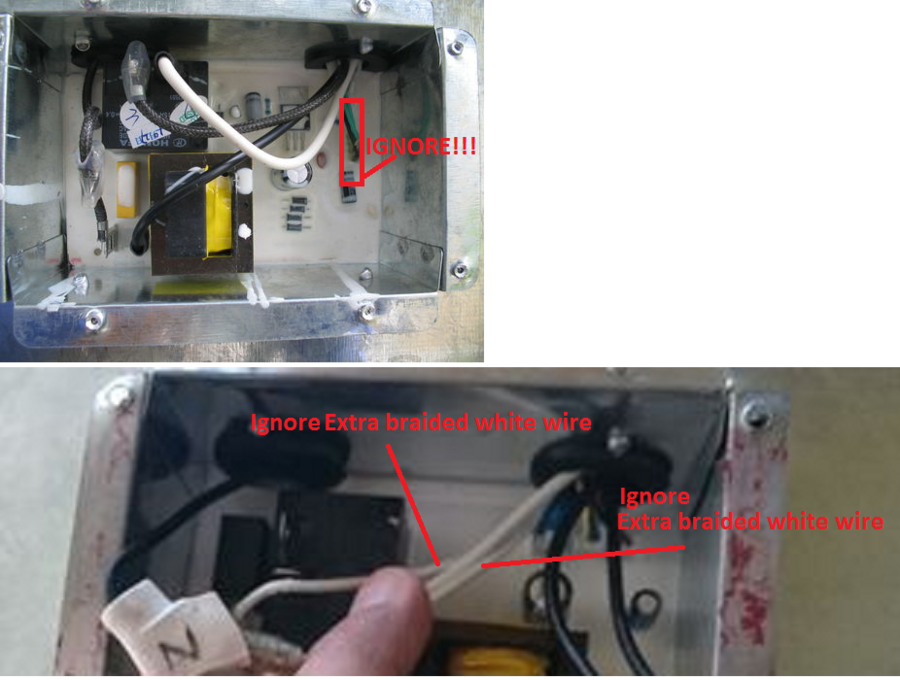

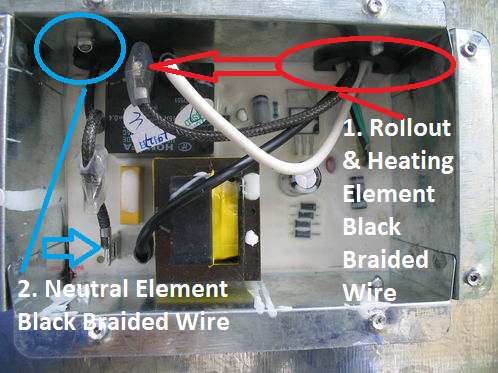

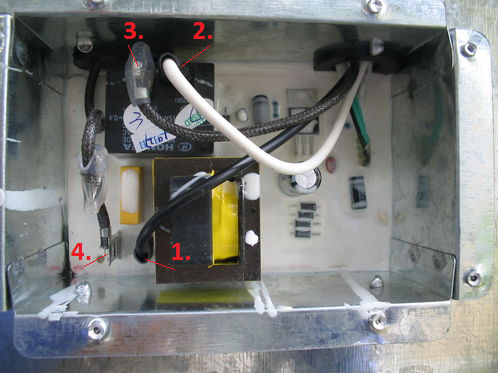

The bigger 16AWG size braided wires (braid color may be different than below) will be the ones that run to the Heating element and to the Safety Rollout Limit switch which then runs again to the other connector the heating element. So for example in this picture:

- Wire#4 runs directly to the Heating Element prong1

- Wire#3 runs to the Safety Rollout Limit Switch

- From the Safety Rollout Limit switch #3 will continue to the Heating Element prong2

- Wire#1 is the Hot wire from the MES plug

- Wire#2 is the Neutral wire from the MES plug

If you unhook the braided wires from the circuit board AND unhook the braided wires from the heating element you can do a continuity check with your multimeter and identify which ends match up. What it wont tell you is which which wire has the safety rollout limit switch in the mix, but we'll get to that later.

The simple rewire would be to unhook wires 1-4, cut off their ends.

Then splice a smooth wire (1 or 2) with a braided wire (3 or 4), order does not matter. The only thing that matters is that a smooth goes to a braided. Once each smooth is spliced to a braided you are done!

Back to the Safety Rollout Limit Switch now.

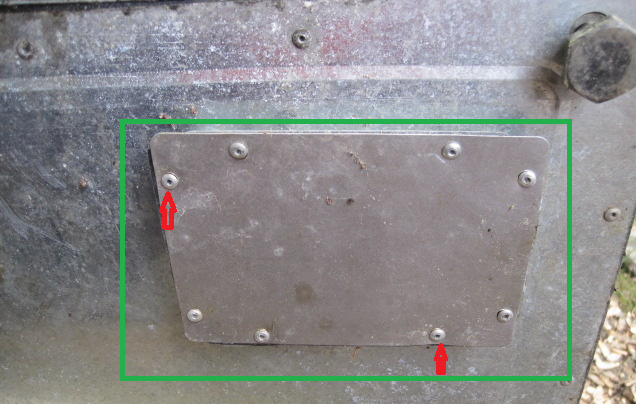

On the Back of your MES (not under) you will find a panel for the heating element.

If you have a 2nd panel about halfway up (middle or right side usually) then THAT panel will be the Safety Rollout Limit Switch.

If you have no 2nd panel halfway up... well you probably want to cut one because that switch is a major failure point for both the connectors corroding away AND the cheap plastic switch melting down once the connectors begin corroding. I'd bet money the connectors are already corroding because that's what the

Masterbuilt connectors do best :D

If you don't care to mess with the switch and it is working then feel free to stop reading here, if it fails on you later (smoker wont heat up) then start reading again from this point :D

If you look INSIDE your MES on the back wall you will see a round button looking thing the size of a quarter. That is the Safety Rollout Limit Switch.

Use a tape measure and you can figure out where it is located on the back OUTSIDE of the MES. You will want to cut yourself a panel to get to this thing. So cut about a 6inch tall by 4 inch wide rectangle here and then cover with a piece of sheet metal and self tapping sheet metal screws when done, panel created!

I would use a dremel or oscillating tool with a blade that can cut through thin metal and carefully make the cut. There is usually a box covering the switch that you have to unscrew off to get to the switch so chances are you won't cut a wire but it may still happen :)

I hope all this info helps :)

very nice write up and tutorial. I am at my wits end with (2) MES30's exhibiting different symptoms.

Masterbuilt tech are dick heads and due to my limitd dexterity due to stroke I am at my wits end. Right now I have to "ride th board" and keep a close eye out on internal temps on one unit that doesnt like to not turn off element and scorches to 300 degres. The other sems to turn on and off, but the internal tmp(as mesure by gate level

inkbird probe, is typically 25 degrees higher than displayed tmp on PID (I think that;s what it is cslled.

that's all

thank you

john

Hi John.

Well sounds like the MES that doesn't want to shut off probably has a faulty circuit board in the panel underneath the MES. I doubt you can find the replacement circuit board bit if so that would be a simple fix. Without a replacement circuit board your only option is the simple rewire and a PID controller.

The other MES that does cut on/off but runs hotter may actually be a blessing in disguise. It seems most often that an MES unit WONT hit max 275F instead of going over it hahhaa.

If yours cuts off/on but swings high then you should be able to lower your set temperature and wing it from there. Not a bad problem to have.

Now temp swings suck no matter what but the swings are what

Masterbuilt uses unfortunately so they can ensure wood chips burn.

The only surefire wire to eliminate the temp swings is a rewire and PID controller.

I think with this unit you may be able to just lower your set temp and be good to go, but yeah still a little dissapointing.

Now a rewire is not hard to do when it comes to the electrical work BUT you may definitely want someone to help pick the thing up and flip it around etc. They are not feathers for sure and I lift mine onto a heavy duty foldout table to work on them so I'm not laying on the ground or squatting all day.

This will be the most difficult part for you by far.

If you decide you want to do the rewires and put in PID controllers let us know. We have the knowledge here to help. You will have to source the muscle though :D

![DSC_0303[1].JPG](/media/dsc_0303-1-jpg.528634/full?d=1507244980)

![DSC_0302[1].JPG](/media/dsc_0302-1-jpg.528632/full?d=1507244980)