Blunderbuss

Newbie

- Feb 22, 2021

- 16

- 5

got it, thanks! I'm doing my first smoke today, and as everyone has said the MES40 fluctuates with a 20 degree range. An Auber is starting to look nice... :)

got it, thanks! I'm doing my first smoke today, and as everyone has said the MES40 fluctuates with a 20 degree range. An Auber is starting to look nice... :)

I was able to do a very simple and nondestructive rewire that leaves all the original functionality - the interior light, the door-open warning chime, even bluetooth (as useless as it is) and the original temp. sensor. The smooth white and braided blue cables are the plug and controller neutral, and are already connected to each other at the board - so I left them. Then, to remove the relay from the circuit (preventing the stock controller from doing anything to the heating element), I detached the braided red cable and used needlenose pliers to open its connection. I then fit it around the smooth black hot-plug cable and used the pliers to make sure it was solidly on there. By leaving the smooth black plugged into the relay, the rest of the box gets the power it expects; but the heating element also sees that full power, rather than sitting on the other side of the relay from it. If I ever want to undo this, all I have to do is slip off the red braided cable and put it back onto the relay post. No wire cutting, stripping, or wire-nuts required at all.

I have a Masterbuilt SE model #20075515 and it stopped heating. I replaced the heating element but that did nothing. Masterbuilt suggested it was the control panel or the power control board, but you can no longer buy those parts anywhere. The control panel all works fine, I replaced the relay switch on the power control board, after doing that it now gets the "click" sound when powering up and setting the temp, yet still no heat. Multimeter shows the heating element(s) (I tried with both the old and the new) are getting power, yet still no heat. Any suggestions on what else to try, or should I go for this PID rewire I keep reading about?

Hi there and welcome!

I common failure point is the safety rollout limit switch.

Now you may be getting power at first to the element but if the connectors are loose or failing at the safety rollout limit switch it will heat up and think the smoker temp is over 300F and cut power off to the element.

If you look inside your smoker against the back wall it will be a quarter sized circle sensor.

If you have an access panel to get to it, it will be in the same location but on the back wall of the smoker. Check that out. You can always wire around the switch to get by or replace with an existing . These EXACT ones are replacements. There are 2 styles and one style wont work at all this EXACT listing is the style that will work so dont let less expensive prices steer you to buy the wrong part:

Also use some hi temp connectors at the switch and at the heating element.

Check that out and let us know if that is the issue. If it is not then you can talk PID controller and rewire if you cannot find the current issue :)

The safety rollout limit switch was the culprit. The Amazon delivery arrived late Sunday morning, and within minutes, I had the MES up and running , even with the old heating element. Thank you for the info, I really appreciate it!

Anyone have PID settings for MES40 + Auber WSD-1500H-W ?

Ok so my MES30 is finally acting up so I decided to go full bore and get the AW-WST1510H-W controller. I need to do this wire re-work in order to use this correct. Also are there any here is what you should set etc. I have never used a PID, but from what people have been saying it is the way to go. Thanks for any input.

My Masterbuilt 20075315 is as dead as Thomas Jefferson. Won't turn on at all. Masterbuilt support is of course worthless, and the controller is no longer made. Not having read anything, I opened the back panels and found some severely corroded connectors and fixed them, but now having read these threads, I realize they are the Heating Element connectors.

Anyway, I'm about to invert the smoker and access the panel (genius design guys, put the panel on the bottom and rivet it). I'm assuming the wires are corroded like the Heating Element connectors. I'd like to test it before springing for a PID. But what else could it be? Pretty simple device if you bypass the motherboard, right?

I assume the AW-WST1510H-W is the gold standard these days? Definitely love the wifi idea so I can leave the house and keep tabs on things.

Nice find on the damage to the board!OK, I bypassed the control unit by connecting the molex-type connectors, and plugged it in, and the smoker heated right up.

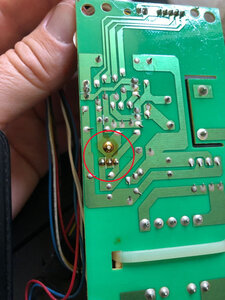

Examining the control board, you can see what appears to be heat damage at the solder points for the lone MOSFET on the board, so yeah that MOSFET was probably fried:

View attachment 513413

Anyway, I'm looking at the AW-WST1510H-W PID so I have WiFi. Is that pretty much the top recommended PID?

View attachment 513414

Thanks!

I will do that. Thanks.lunchboxfl If you have some silicone use that to hold it in place . Couple dabs on each of the sides . If you need to get back in there , use a utility knife to cut it loose .