- Feb 24, 2015

- 212

- 24

My saga continues. I have a Gen 1 (one of them) MES that I had for maybe or 5 years. It died after maybe 18 months, so I changed the element with no luck, then changed the little round thermostat with no luck. So it sat in storage for 3 years until I had a buddy help me test the parts. Turns out it was the little round thermostat. The one I replaced must have been bad because as soon as we bypassed it, the smoker cranked right on up to 250. So I ordered new ones, and got them in a couple of days ago. I just plugged the wires into it and left it dangling out of the smoker, just to test if the one on was good. Again, the smoker fired up and ran at 250 for a couple of hours. Rejoice!!

So last night, I screwed it into the smoker, put the back plate back on (which is a huge pain in the rear!) and fired up the smoker to 275 to burn off mold and other gunk that grew inside for the past 3 years. I checked it a couple hours later and it was at 81 degrees and would not get warmer. What gives? The thermostat is supposed to go up to 150 c (302f) and it only seemed to work when it was outside of the unit, the ambient temp of the garage was probably 40 degrees a couple of nights ago when I tested it, but last night when it was actually detecting temp inside the smoker it wouldnt let it heat past 81 f degrees.

Im beyond frustrated!

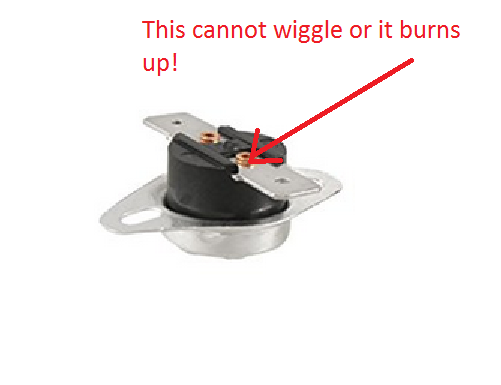

Here is the thermostat I ordered and tested fine outside of the unit, but something is not letting the unit heat past 81 when its inside the unit. If you click the image it will take you to the amazon page I bought it from with its specs.

So last night, I screwed it into the smoker, put the back plate back on (which is a huge pain in the rear!) and fired up the smoker to 275 to burn off mold and other gunk that grew inside for the past 3 years. I checked it a couple hours later and it was at 81 degrees and would not get warmer. What gives? The thermostat is supposed to go up to 150 c (302f) and it only seemed to work when it was outside of the unit, the ambient temp of the garage was probably 40 degrees a couple of nights ago when I tested it, but last night when it was actually detecting temp inside the smoker it wouldnt let it heat past 81 f degrees.

Im beyond frustrated!

Here is the thermostat I ordered and tested fine outside of the unit, but something is not letting the unit heat past 81 when its inside the unit. If you click the image it will take you to the amazon page I bought it from with its specs.