- Sep 7, 2013

- 106

- 11

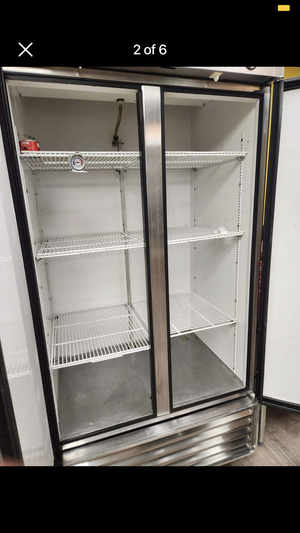

I recently started on this build and ran a smoke course through it last night. Through some pellets on a pan and set on burner. Temp held well around 180-200 but as pellets got hotter was more around 220

I noticed the panels at the end start bowing a little but wondering more about the insulation in there.

Will be be okay if I fasten the panels and sandwich them together with a bolts around the structure???

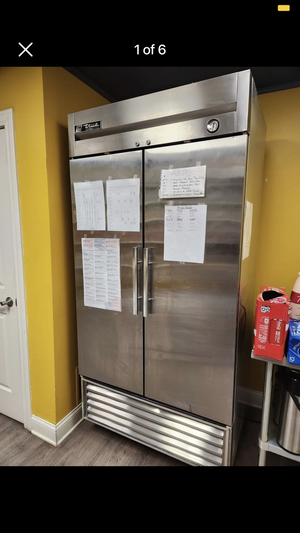

Secondly i can’t find the Mfg tag but it is a true - freezer from the logo on the metal.

Input needed if I continue with it to smoke deer sticks or go another route

There is not a lot around my area at all

Here is some pics

I noticed the panels at the end start bowing a little but wondering more about the insulation in there.

Will be be okay if I fasten the panels and sandwich them together with a bolts around the structure???

Secondly i can’t find the Mfg tag but it is a true - freezer from the logo on the metal.

Input needed if I continue with it to smoke deer sticks or go another route

There is not a lot around my area at all

Here is some pics