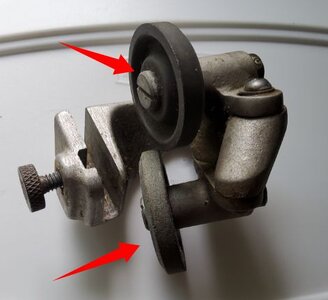

I wanted to try sharpening the blade (I have the grinding attachment--probably worth more than the machine from what I've read) but the stones really do not want to rotate freely.

1)Are they supposed to rotate freely or are they supposed to resist rotation when placed against the spinning blade?

I didn't want to try sharpening because of this resistance.

I would think 'yes' so my primary question is: what is the best/safest way to clean them? I'm guessing they are gummed up with old grease. They come off (screw) really easily but the axles seem to be "attached for life".

Thanks for any tips.

1)Are they supposed to rotate freely or are they supposed to resist rotation when placed against the spinning blade?

I didn't want to try sharpening because of this resistance.

I would think 'yes' so my primary question is: what is the best/safest way to clean them? I'm guessing they are gummed up with old grease. They come off (screw) really easily but the axles seem to be "attached for life".

Thanks for any tips.