I did my first smoke on Jan 1st (two 3 lb butts and 2 chickens). By the end of the day I just wanted it to be over. Turned out very well, but it just stressed me the heck out. I did my second smoke yesterday, 7 lb butt and two chickens and it was a breeze. My only regret is not starting the butt the minute I woke up. Instead, I waited about two hours. Overall, it turned out very well and I'm very happy and one 7 lb butt was much better taste-wise than two 3 lb butts.

My wife was sick when I did my first smoke, and she wasn't impressed at all with the outcome. By the time she was better, we (or more accurately, I) had eaten it all. Last night, when we sat down to eat our chicken dinner she was really impressed with it. She was amazed with how good it was and couldn't stop eating it. No more buying grocery store rotisserie chickens for us!

Here's my log from this most recent smoke:

[h1]January 11, 2014[/h1]

7 lb butt, and two spatchcock chickens. Butts rubbed with Jeff’s Rib Rub and chickens placed in Wine Brine night before.

8:00 AM Smoker preheated. Cherry wood chips put in water.

8:30 AM Butt and wood chips placed in the smoker.

11:20 AM Chickens rubbed and placed in smoker, used rest of cherry wood chips.

12:00 PM Added apple wood chips.

1:30 PM Foil placed over top of tray, apple juice poured into tray. Apple juice sprayed on chicken.

4:00 PM Chickens removed at 180°F

10:00 PM Butt removed at 190°F, just a bit on the low side. Placed in cooler overnight. Juices put into glass and put into fridge.

7:00 AM Butt pulled. Fat removed from juices. Glass with congealed juices placed in pot of water. Pot placed on stove on low heat. Butt put in oven to keep it warm at 170°F.

8:00 AM Butt dried out just a little bit, but still very tasty. Juices poured over butt.

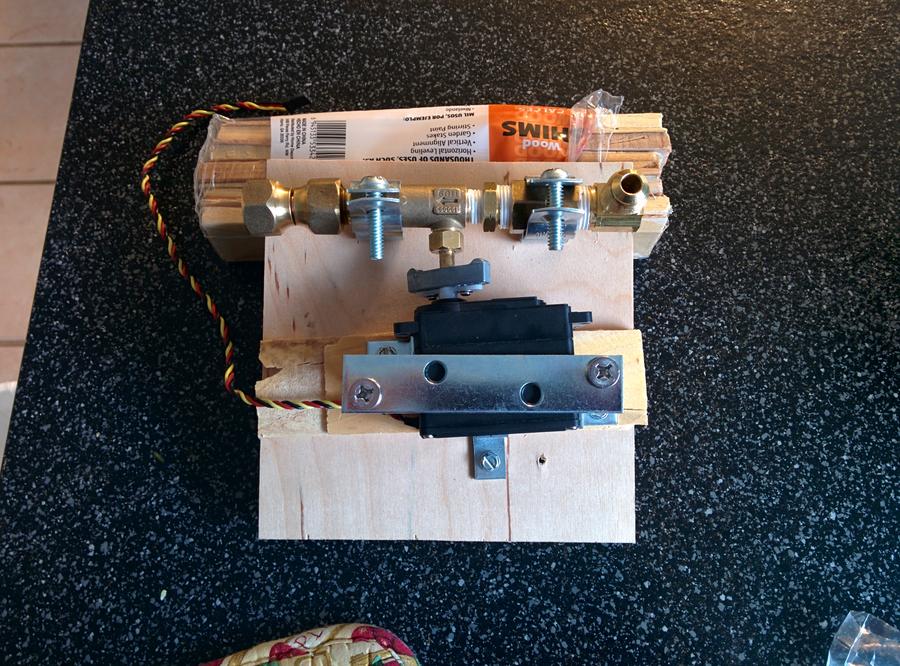

I bought a needle valve too, to help more finely control the temperature of the system. There seems to be some large black box connected to it which has made it cumbersome to use at the moment. Guess I'll have to figure out some way to take advantage of that

https://www.dropbox.com/s/kvansm5q9qqh2cv/2014-01-10 14.12.38.mp4

My wife was sick when I did my first smoke, and she wasn't impressed at all with the outcome. By the time she was better, we (or more accurately, I) had eaten it all. Last night, when we sat down to eat our chicken dinner she was really impressed with it. She was amazed with how good it was and couldn't stop eating it. No more buying grocery store rotisserie chickens for us!

Here's my log from this most recent smoke:

[h1]January 11, 2014[/h1]

7 lb butt, and two spatchcock chickens. Butts rubbed with Jeff’s Rib Rub and chickens placed in Wine Brine night before.

8:00 AM Smoker preheated. Cherry wood chips put in water.

8:30 AM Butt and wood chips placed in the smoker.

11:20 AM Chickens rubbed and placed in smoker, used rest of cherry wood chips.

12:00 PM Added apple wood chips.

1:30 PM Foil placed over top of tray, apple juice poured into tray. Apple juice sprayed on chicken.

4:00 PM Chickens removed at 180°F

10:00 PM Butt removed at 190°F, just a bit on the low side. Placed in cooler overnight. Juices put into glass and put into fridge.

7:00 AM Butt pulled. Fat removed from juices. Glass with congealed juices placed in pot of water. Pot placed on stove on low heat. Butt put in oven to keep it warm at 170°F.

8:00 AM Butt dried out just a little bit, but still very tasty. Juices poured over butt.

I bought a needle valve too, to help more finely control the temperature of the system. There seems to be some large black box connected to it which has made it cumbersome to use at the moment. Guess I'll have to figure out some way to take advantage of that

https://www.dropbox.com/s/kvansm5q9qqh2cv/2014-01-10 14.12.38.mp4