Has anyone ever converted their digital MES over to just simple manual controls? I’ve had mine for a few years and don’t remember the exact model (larger of the stainless & glass ones Academy sells with the digital controls on the top rear). It’s mostly performed well with no problems but during a hurricane last year the plastic around the buttons crumbled, allowing water to get into the control panel beneath.

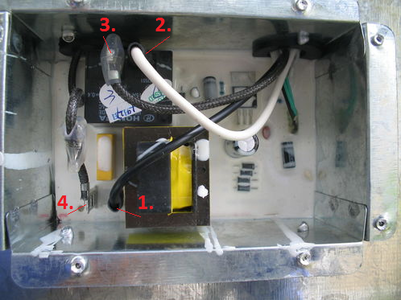

I just took it apart to see if it looked worth messing with and there‘s enough rust and corrosion on the circuit board from staying wet that I don’t think it’s repairable. Also: the bluetooth and other features never worked enough to bother with in the first place, so all I’ve ever used the control pad for is setting the temp and monitoring the temps for the smoker and probe. I can do that with a separate probe and analog thermometer just fine.

What I’m wondering is whether I can just somehow get rid of the control pad altogether and operate the smoker with a simple generic electric oven control (temperature dial, either thermostat that comes with the controls or wire it into the existing smoker thermostat, and wires out to kick the element on and off as the temperature calls for.

There’s no way to replace the Masterbuilt parts for less than at least half the price of a new smoker, but generic analog electric oven controls can be had off of eBay and such for $5-10 all day long.

Just figured I’d ask as I can’t imagine I’m the first one to consider going this route.

I just took it apart to see if it looked worth messing with and there‘s enough rust and corrosion on the circuit board from staying wet that I don’t think it’s repairable. Also: the bluetooth and other features never worked enough to bother with in the first place, so all I’ve ever used the control pad for is setting the temp and monitoring the temps for the smoker and probe. I can do that with a separate probe and analog thermometer just fine.

What I’m wondering is whether I can just somehow get rid of the control pad altogether and operate the smoker with a simple generic electric oven control (temperature dial, either thermostat that comes with the controls or wire it into the existing smoker thermostat, and wires out to kick the element on and off as the temperature calls for.

There’s no way to replace the Masterbuilt parts for less than at least half the price of a new smoker, but generic analog electric oven controls can be had off of eBay and such for $5-10 all day long.

Just figured I’d ask as I can’t imagine I’m the first one to consider going this route.