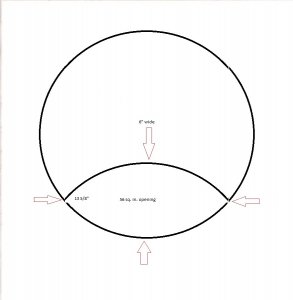

This will be my first RF build. I'm have 1/4 inch pipe 18 inch ID.

CC 18"x45" =11451 CI

FB 18"x18" round =254 CI

So I used Dave's (thanks Dave) calculations and came up with 45.8 CI opening FB/CC. This where I'm Confused is this considered a long and narrow smoker if so do I need to add 20-30% to the opening?

Thanks Rich

CC 18"x45" =11451 CI

FB 18"x18" round =254 CI

So I used Dave's (thanks Dave) calculations and came up with 45.8 CI opening FB/CC. This where I'm Confused is this considered a long and narrow smoker if so do I need to add 20-30% to the opening?

Thanks Rich