This one, Keith?

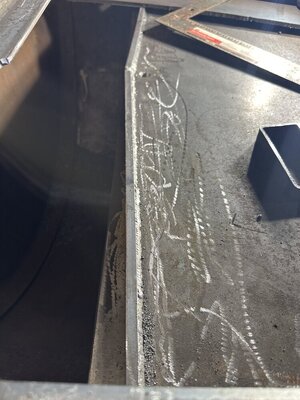

Finished my first build

Some of you have probably seen some of the pictures since I've been asking random questions on other subforms here. But nothing much to say, just hear some pics in case anybody is doing some research in the future and looking for ideas. 120 gallon tank, 24x27- Fireboxwww.smokingmeatforums.com

Thanks guys I think I can do that. Maybe that is a good idea. It will make the exhaust easier to handle to get onto the smoker since it is 8” pipe and heavy. Plus be able to still build it in the shed and get it out. lolYup.. That's the one...

irvin... take a look at that thread...