So, my masterbuilt propane fired smoker is on its last legs. burner area starting to rust out. on second burner, so I know it won't survive another rebuild.

I've been thinking about building a smoker for a while. a 100lb propane tank would give me a similar cooking area to the MB.

I went to feldons calculator based on common 100lb tank sizes i came up with these numbers

cook chamber 8478 ci

Firebox rec 2826 ci

i figure a 15x15x15 firebox would size which gives me a fb of 3375 ci

a 3" Dia chimney needs to be 24" tall

FB intake 10.13 sqin

and a FB to Cook opening of 27 sqin

so questions

1. is there a best space for the baffle plate, Ie x inches below first rack or X inches above FB opening

2. I was thinking of doing two racks. one at the widest point of tank, and a second rack 4" above main rack. would be a smaller rack, but would be good for thin items like ribs or brisket and could also be removed if I needed to cook a taller item, turkey, beef roast, ect.

3. i really like the propane heat aspect of the MB, predictable and fool proof. I have an old turkey fryer burner that I could utilize. I'd have to build a chip/chink tray, But also want to keep the option open for being charcoal/stick fired. thoughts?

4. Chimney. How deep into the cooking chamber do you put it. the deeper you put it the potentially more smoke that lingers. Yes?

5. does it matter where on the firebox the door is. IE can it be on the same side as the cookchamber opening.

6. can i use the top of the firebox as a "stove top" for heating sauces, or simmering items in pots?

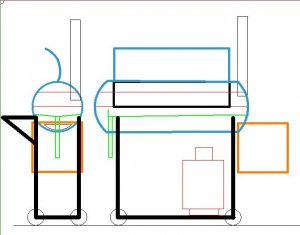

here is a prelim sketch in cad...

I've been thinking about building a smoker for a while. a 100lb propane tank would give me a similar cooking area to the MB.

I went to feldons calculator based on common 100lb tank sizes i came up with these numbers

cook chamber 8478 ci

Firebox rec 2826 ci

i figure a 15x15x15 firebox would size which gives me a fb of 3375 ci

a 3" Dia chimney needs to be 24" tall

FB intake 10.13 sqin

and a FB to Cook opening of 27 sqin

so questions

1. is there a best space for the baffle plate, Ie x inches below first rack or X inches above FB opening

2. I was thinking of doing two racks. one at the widest point of tank, and a second rack 4" above main rack. would be a smaller rack, but would be good for thin items like ribs or brisket and could also be removed if I needed to cook a taller item, turkey, beef roast, ect.

3. i really like the propane heat aspect of the MB, predictable and fool proof. I have an old turkey fryer burner that I could utilize. I'd have to build a chip/chink tray, But also want to keep the option open for being charcoal/stick fired. thoughts?

4. Chimney. How deep into the cooking chamber do you put it. the deeper you put it the potentially more smoke that lingers. Yes?

5. does it matter where on the firebox the door is. IE can it be on the same side as the cookchamber opening.

6. can i use the top of the firebox as a "stove top" for heating sauces, or simmering items in pots?

here is a prelim sketch in cad...