I am now the proud owner of a 24" diameter tank X 81" long. I also found on the same day a trailer which with some modification should work just fine for this build. I have been reading and following all the builds currently going on and have read many of the completed build threads also. There is a wealth of information on this site. I plan to build a traditional offset reverse flow smoker. It looks like my main cookling chamber will be about 57" with the other 24" of the tank being used for the firebox. I have read all the info here on cutting the tank and that will be my first task after cleaning it out. It is currently full of soapy water awaiting cutting. Going to need lots of help from you guys and gals. Thanks, Joe

Starting my first Reverse Flow Build

- Thread starter weedeater

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Thanks Jarjarchef. I will need a lot of help. Had wanted to get this build done by Thanksgiving but that deadline will not be met. Hoping now for by Christmas or New Years. Here is a pic of the nasty, smelly, propane tank that will hopefully be transformed.

jabbo

Meat Mopper

stonebriar

Meat Mopper

Made some good progress this weekend and today on the smoker. Got the firebox cut off the tank. Got the hinges on for the door and the door cut out. Got the flange welded on the door. Have been debating for some time on how to position the firebox into the main smoking chamber. The main debate was on which way to orient the firebox. Domed end into the smoker which leaves a flat end for the firebox door but a more difficult cut joining the two or domed end out which makes for a more difficult door on the firebox. The later won out based primarily on how it looked to me and balanced out better with domes on both ends.

Got started working on the door for the firebox. Got it framed up with angle iron and the cut made in the dome end. Ending up fitting pretty good after what seemed like a couple of hours of grinding some tight spots to get the angle iron to sit in just right.

The small piece of steel sitting on top of the firebox will become the slide for the air inlet underneath the firebox. I will put a second vent in the door for fresh air inlet above the fire level. What do you think guys?

jabbo

Meat Mopper

ribwizzard

Master of the Pit

Thanks Jabbo and Ribwizzard for the encouragement! I have looked at your builds and some mighty good looking Qviews too. I haven't had time to work much on the build in the last day or two. Something about Thanksgiving being tomorrow and we are expecting upwards of 57 family for lunch. Thankfully we are not doing all the cooking but we have been rather busy since we are hosting. A shame we don't have this build done but maybe next time. I did manage to find a little time today to work on the slide for the airvent under the firebox. It's not too pretty but should be functional for the main air supply under the firebox.

The top photo shows the slide completely closed and the next one shows it fully open. Will work on the slide lever after we get through Thanksgiving tomorrow. That is if I can move after eating way to much turkey and all that goes with it and more. Happy Thanksgiving to all!!!

The top photo shows the slide completely closed and the next one shows it fully open. Will work on the slide lever after we get through Thanksgiving tomorrow. That is if I can move after eating way to much turkey and all that goes with it and more. Happy Thanksgiving to all!!!

dragons breath

Meat Mopper

Nice looking air damper. I like the curved feature. It's more work but gives it that look.

Once you clean it up and paint it it'll be fine. It's to bad it'll be on the bottom so folks can't see it.

Next time how many turkeys do you need? You got it covered.

Once you clean it up and paint it it'll be fine. It's to bad it'll be on the bottom so folks can't see it.

Next time how many turkeys do you need? You got it covered.

Thanks Dragon Breath for the kind words. The curved slide was about the only way I could figure to get the main vent under the fire short of framing it up with angle iron to make it flat like I did for the firebox door. I was real happy with the cut for the firebox door but figured I would really be pressing my luck to try that again. The door frame ended up fitting in pretty good but that was after a couple of hours of grinding off what looked like 1/32" in a spot or two. I would grind and then try it and then mark and grind some more and more and well you get the picture. Didn't want to go through that again. The piece I used for the slide was part of the waste I cut out of the main cooking chamber where it will join the firebox under the RF plate. Since it came off the tank it has almost the curve that I needed. Just had to flatten it out a little to fit perfectly.

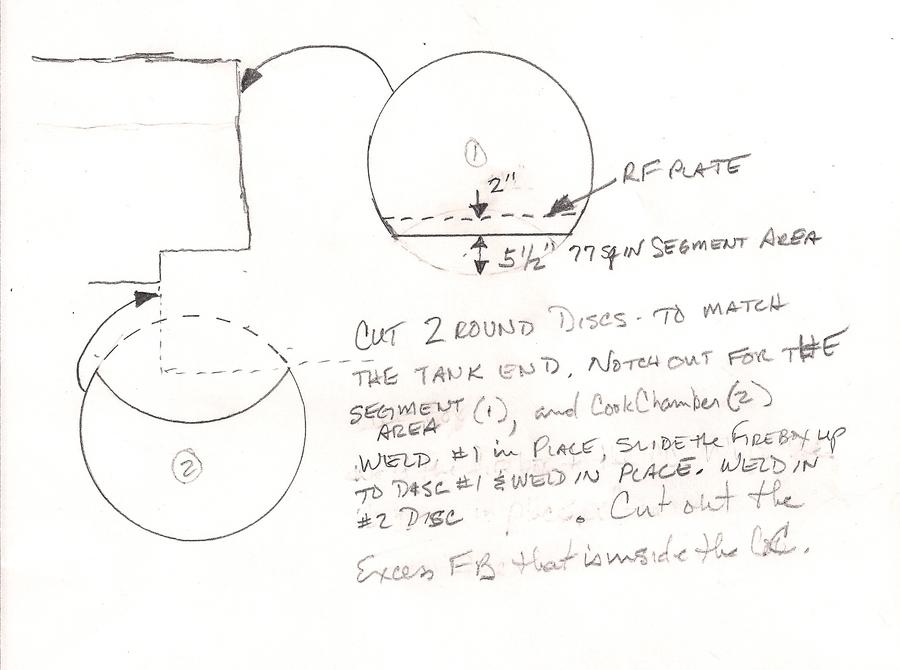

Joe, morning.... I thought about your question and came up with an idea..... Hope it makes sense..... This idea is based on your pictures of the smoker parts..... Dave

click on pic to enlarge

click on pic to enlarge

rasimmo

Meat Mopper

I plan on doing something similar with my firebox door. I was thinking of using 3/8 flat instead of angle though, with a lip around the outside of the door that goes over the flat a little. Do you think that would be strong enough, or should I use angle as well?

I think the flat bar would probably be strong enough and if you are going to put a lip on it you are in effect making a piece of angle iron of some kind which would add strength also. I just wanted to be sure with mine and the angle iron also gave me a strong attachment area for the hinge. This part of the smoker will get a lot of wear as you load wood into it. I have got the door to the firebox finished with some more dampers. I will try to get some pics up tomorrow if I can.

Finally getting back to work on the smoker. Got the rf plate and drain welded in.

Got the door for the firebox fabricated along with the sliding air vent. Got it hinged and installed on the firebox.

Working on building a sled for the smoker to sit on that will ultimately provide the attachment points to the trailer. Hopefully this will help in being able to get the weight distributed properly on the trailer. Hope to have this done in next day or two and will get more pics posted.

Got the door for the firebox fabricated along with the sliding air vent. Got it hinged and installed on the firebox.

Working on building a sled for the smoker to sit on that will ultimately provide the attachment points to the trailer. Hopefully this will help in being able to get the weight distributed properly on the trailer. Hope to have this done in next day or two and will get more pics posted.

Ok, Got the sled built for the smoker and managed to get it under the smoker after some initial challanges. Tough to move around with limited equipment but got it done.

Also got the smokestack cut and inserted in. Beginning to look like a real smoker. Weather turned nasty so I couldn't get it welded in yet. Hopefully will be able to get it welded in along with the end cap on that end over the weekend. This will get me close to being able to think about firing her up see how she is going to perform. Going to pick up the metal for my grates the first of the week. This will get the smoker just about done. Next will come serious work on the trailer and some of the detail work on the doors, vents, etc.

Also got the smokestack cut and inserted in. Beginning to look like a real smoker. Weather turned nasty so I couldn't get it welded in yet. Hopefully will be able to get it welded in along with the end cap on that end over the weekend. This will get me close to being able to think about firing her up see how she is going to perform. Going to pick up the metal for my grates the first of the week. This will get the smoker just about done. Next will come serious work on the trailer and some of the detail work on the doors, vents, etc.

rasimmo

Meat Mopper

Looking good.

How much of the firebox is in the cook chamber? I am curious to see the outcome of the temps with it like that.

I hear ya on the weather, been raining here since I got home. It is supposed to be nice tomorrow. Maybe I can get started on mine.

How much of the firebox is in the cook chamber? I am curious to see the outcome of the temps with it like that.

I hear ya on the weather, been raining here since I got home. It is supposed to be nice tomorrow. Maybe I can get started on mine.

There is 10 inches of the firebox inset into the cooking chamber. I think this will result in that end of the cooking chamber running 30 to 50 degrees hotter than the other end. I don't see this as a negative but as a positive to be able to cook at 2 different temps at the same time in the same smoker. If it is a problem I can always make some mods with a baffle but right now I am hoping to have the ability to crank it up on the firebox end.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 3

- Views

- 1K

- Replies

- 6

- Views

- 4K

- Replies

- 2

- Views

- 10K

- Replies

- 131

- Views

- 12K

- Replies

- 10

- Views

- 2K

Hot Threads

-

Is anyone here in the automotive or truck sales business?

- Started by forktender

- Replies: 33

- General Discussion

-

Finally...

- Started by Gonna Smoke

- Replies: 24

- Slicers, Grinders, Tools, Equipment

-

Bucket list Smoker - Humphrey's Pint

- Started by dward51

- Replies: 17

- General Discussion

-

Tomatoes

- Started by Gonna Smoke

- Replies: 14

- Blowing Smoke Around the Smoker.