- Aug 27, 2016

- 1,334

- 462

I heard leaving the bark on fruit woods is good.

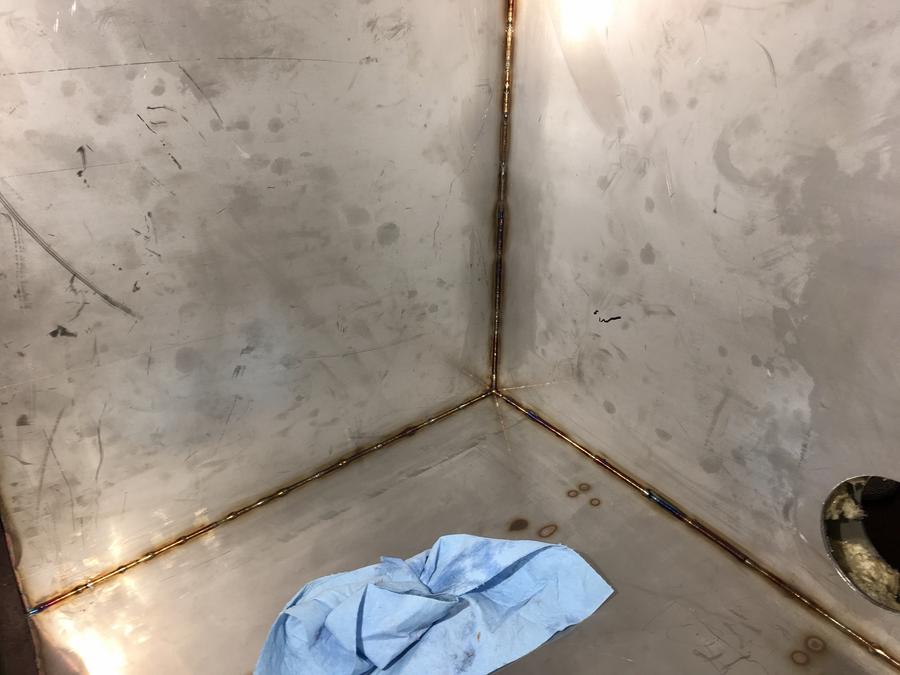

Been making progress on the smoker heres where I am now. Doing the pluming on the second runner going up to the cc. It's 3.5 OD with 1/4 wall

Been making progress on the smoker heres where I am now. Doing the pluming on the second runner going up to the cc. It's 3.5 OD with 1/4 wall