- Jun 4, 2019

- 48

- 19

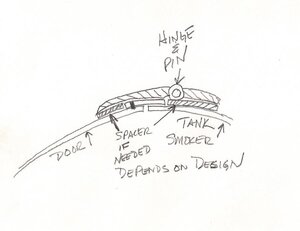

Finally decided it's time to build my stick burner. Currently I smoke on a Green Mountain, Rec Tec, or my PK but I want something I can play with a little more.

I picked up a 60 gallon air tank (20inx44in) and a 15 gallon air tank. I did all of my calculations based on DaveOmaks thread, and came up with the following:

FB/CC opening = 55.44 in

Area under RF plate = 55.44

Area at end of plate = 55.44

Air intake area = 13.86" (will do around 3" for the upper and 11" for the lower)

Exhaust stack volume = 305 cubic in

Exhaust Stack = 4" diameter by 24" height

RFplate width = 17"

Height of FB/CC opening= 4.75"

Do these numbers look accurate? The only other question I have is on my fire box. My 15 gallon tank is a little smaller than suggested. A 20 gallon would have been better but I couldn't find one for a reasonable cost. Will the 15 gallon tank be a problem or should I fab one up out of steel? Looking forward to getting this thing up and smoking!

I picked up a 60 gallon air tank (20inx44in) and a 15 gallon air tank. I did all of my calculations based on DaveOmaks thread, and came up with the following:

FB/CC opening = 55.44 in

Area under RF plate = 55.44

Area at end of plate = 55.44

Air intake area = 13.86" (will do around 3" for the upper and 11" for the lower)

Exhaust stack volume = 305 cubic in

Exhaust Stack = 4" diameter by 24" height

RFplate width = 17"

Height of FB/CC opening= 4.75"

Do these numbers look accurate? The only other question I have is on my fire box. My 15 gallon tank is a little smaller than suggested. A 20 gallon would have been better but I couldn't find one for a reasonable cost. Will the 15 gallon tank be a problem or should I fab one up out of steel? Looking forward to getting this thing up and smoking!