- Jan 16, 2023

- 10

- 18

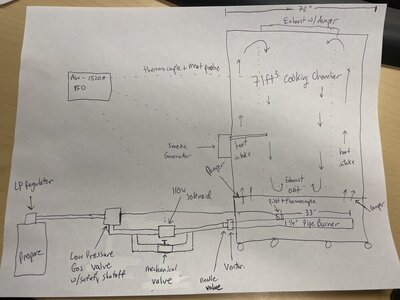

Currently building a 70 cubic ft upright reverse flow smokehouse. Will mainly be used for sausage but hope to also be able to go higher temps for brisket/pork butt, etc and lower temps for cold smoking cheese/salami.

Found lots of useful info here on a setup using PID controller, safety valve/thermocouple, solenoid for high flow and a separate line around the solenoid to keep constant low flame in the burner.

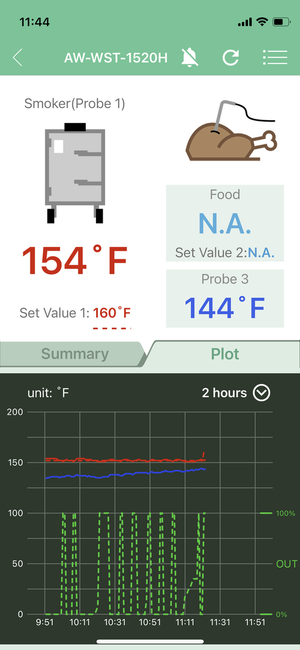

The setups I have seen on this site keep the low flow going over the entire burner at all times with the PID opening the solenoid and adding flow when the temp needs to rise. I'm worried that this constant flame would keep the temp in the cooking chamber higher than 140* and for sure too high for cold smoking cheese/salami etc.

Would it make sense to install a pilot light with thermocouple so that only the pilot burns when the solenoid is closed. Once the solenoid opens the main burner lights from the pilot. Any downsides to this type of setup?

Found lots of useful info here on a setup using PID controller, safety valve/thermocouple, solenoid for high flow and a separate line around the solenoid to keep constant low flame in the burner.

The setups I have seen on this site keep the low flow going over the entire burner at all times with the PID opening the solenoid and adding flow when the temp needs to rise. I'm worried that this constant flame would keep the temp in the cooking chamber higher than 140* and for sure too high for cold smoking cheese/salami etc.

Would it make sense to install a pilot light with thermocouple so that only the pilot burns when the solenoid is closed. Once the solenoid opens the main burner lights from the pilot. Any downsides to this type of setup?