Sorry, I will try to clear that up LOL

My warmer is 27"x20"x56" My calculations are about 17 cubic feet.

I have a carport that I will be putting the smoker in and I can run 220v to it no problem, just have to bury the wire. I do have 2 open spots in my breaker box.

I do already have 110v out there.

My idea is to run it 220v and run an oven element. This is the one I am thinking about getting. It is 3000 watt.

https://www.walmart.com/ip/Exact-Re...hguid=d5adcaa6-c22-16c4026a553b59&athena=true

So I would drill a couple holes and run the element connections out the side, connect the wires and cover everything up with a metal shield that is siliconed to keep water out. A little higher on each side I would run 2 smoke daddy smoke generators (I have 2 already) and will need 110 power for those air pumps.

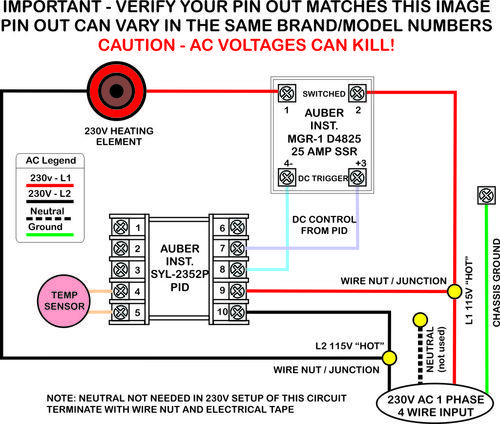

Thinking about running this pid

https://www.auberins.com/index.php?main_page=product_info&cPath=1&products_id=3

This SSR with external heat sink

https://www.auberins.com/index.php?main_page=product_info&cPath=2_30&products_id=30

This Thermocouple

https://www.auberins.com/index.php?main_page=product_info&cPath=20_3&products_id=101

Thinking I will need a switch to turn it all on but dont know what one I would need

https://www.auberins.com/index.php?main_page=index&cPath=69_73

And I think I would need 1 or 2 fuses, also not sure on this style and what amp to use.

https://www.auberins.com/index.php?main_page=product_info&cPath=7_83&products_id=593

I read somewhere that 4 wire is the best, Not sure if that is really the case.

Everything I am seeing says if 4 wire is used that I would not use the neutral.

I have never dealt with 4 wire, not even sure how to hook it up in the breaker box. After seeing your post above I got to thinking if I tied into 1 leg of the power could I use the neutral along with the tie and and create an outlet on the smoker for the 110 air pumps? Its not necessary since I have 110 in the carport but it would be self contained and not need to run a second cord.

Thats basically what I was asking above. If not oh well.

I am thinking about getting 14/3 Type UF-B Cable with ground for running out there and for the wire to go from an outlet to the smoker.

I am not sure what wire to use for all the connections inside the control panel nor do I know what gauge heat resistant wire to get for running to the element.

Hope that helps clarify things. If you can help I would greatly appreciate it.

You can PM me if you need more specifics or I can post them here for others also.

Here are a couple pics of it now. The previous owner used a

turkey fryer and cast iron skillet inside for smoke.