I hear you, and thanks for that. Just trying to get as much as I can right from the start to save myself time later.

Calcs being a good indicator, but not everything. I understand that.

Talking will stop soon, and the real work will begin

But first just a couple of other clarification points.

On the flow dam part, I see and it makes sense.

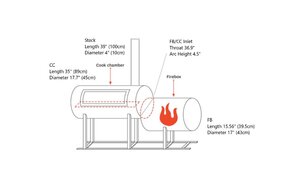

I'm not against dropping the FB at all. I guess this is the flow dam area?

So what you're suggesting is, dropping the FB down quite a bit and maybe going to a half-moon opening?

Thanks on the stack, my guy is pretty good so i think he could manage it without burning through. Will speak to him about the FB input too, seeing him today.

Calcs being a good indicator, but not everything. I understand that.

Talking will stop soon, and the real work will begin

But first just a couple of other clarification points.

On the flow dam part, I see and it makes sense.

I'm not against dropping the FB at all. I guess this is the flow dam area?

So what you're suggesting is, dropping the FB down quite a bit and maybe going to a half-moon opening?

Thanks on the stack, my guy is pretty good so i think he could manage it without burning through. Will speak to him about the FB input too, seeing him today.