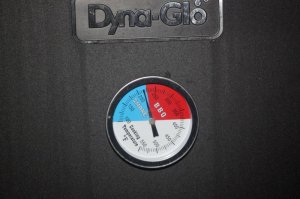

heres the pics i promised, excuse the poor pics it is pouring out, and the sun was just rising, I couldn't wait and started its first burn using lump-hardwood charcoal, vents wide open it would go to 250. easily dampered down to

150 close all vents and poof coals went out, im a happy smoker,

to go above 250 and up all i need to do is barely crack the door,

but this is for jerky and bacon, so im good--I can alway add another pinwheel later ill see how it goes.

I only cut out the front-original vents then placed my sheet holding the two pinwheels over it, using the felt tape and the heat proof goo I bolted it down all along the outside edges,

,

the screen is a bread/baking rack with a zillion holes, I flattened out and bent to fit-been using that far a long time now,

,

the drip-hole is covered with goo and two small casing lids,

this thing now does not leak air

,