Nice turkey.

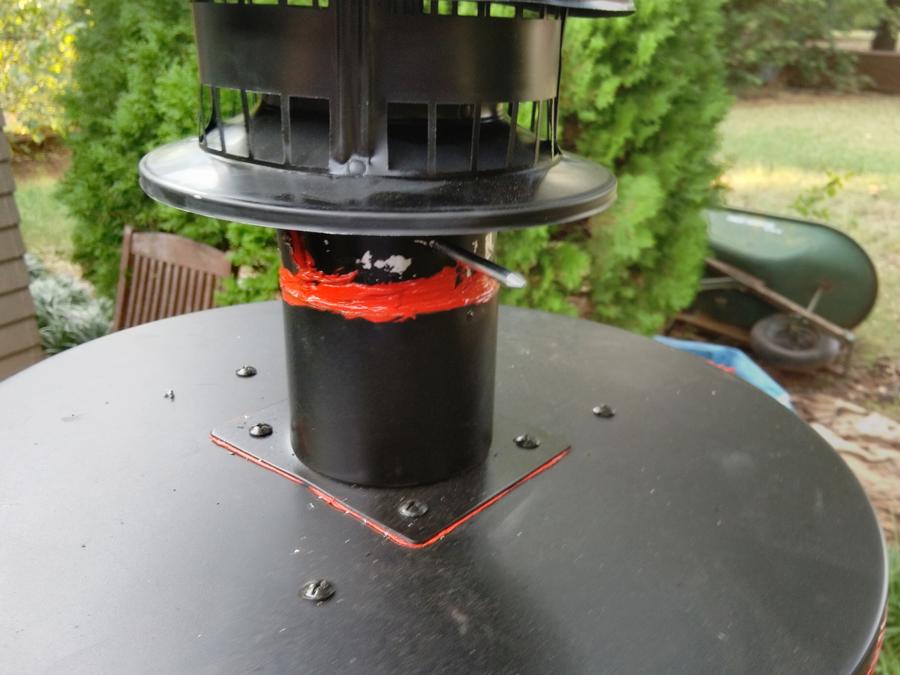

I finally got around to finishing my mods today, am actually waiting on the sealant to cure so I can paint it. The early pics from the assembly and initial mods:

Adding holes to pass my pit and meat probes through to the cooking chamber.

Getting ready to fire it for the first time. I wanted to record temperatures from the bottom to the top to give myself and idea of where the ideal spot for the pit probe might be.

You can't see it too well, but there is a nice gap here when the door is fully closed. Even placing extra gasket here didn't stop the leaking completely. I would have installed the door latches that came with the kit from bbqsmokermods but those push latches would have just made this gap worse.

Curing done, time to load her up and test her out. This was on a Sunday afternoon and since I was off Monday, I decided to do a big cook at about 5pm. We have 2 15lb briskets cut in half, 3 slabs of baby backs and a log of Blue & Gold sausage.

I'm not a foil person, I'm not a mop person and I'm not a baste person. I'm a leave it alone and let it cook person. And let me tell you, those ribs sitting under those briskets soaking up the drippings were wonderful.

Someone decided to stand guard all night while the briskets cooked.

Right over 20 hours after they went on, the briskets hit 195 internal temperature. The stall time on this cook is probably one of the longest I have even seen. This is right before being pulled, wrapped and placed in an ice chest to rest.

I don't seem to have any pictures of the brisket after I sliced it, but it was wonderful.

I didn't like that the smoker leaked like crazy at the top and the bottom because it was just spot welded. And that drip pan is so small it fills up very fast when filling the smoker up with meat. So I ordered a few more things and hope to have the smoker working the way I want it to.