Yup I have Tin can... for now. It works fair in fair weather and if I don't take on too large a task. That's about the best I can say about it

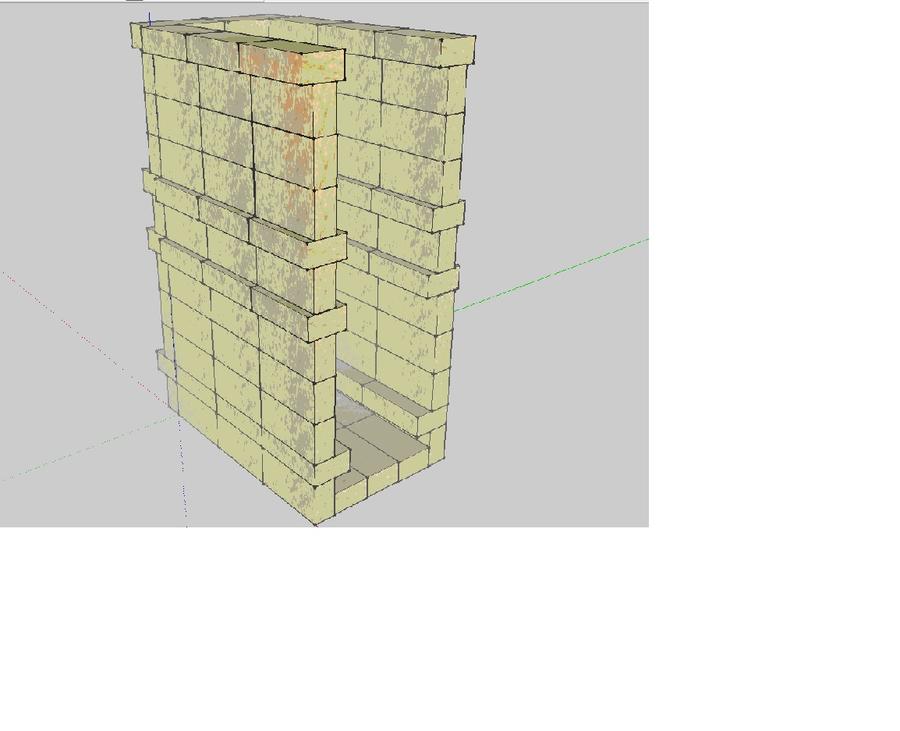

I am in the early stage of planning a brick smoker. Not near as large as the one Wes built.

Seems that some of the key elements for great smoker are:

Accurate Temp control - That requires tight seals and good airflow control (Including placement of inlet vents and the Flue) Digital Thermometer as well.

Heat conservation - Once you get things fired up and up to temp well constructed brick unit should be unbeatable.

Sizing to your needs. I am never going to do even 4 or 5 butts or mega racks of ribs. A modest 2 rack unit is more than enough.

The ability to monitor and top off water pans without loosing all the heat. (Perhaps a 3rd door to access the water pan without opening the main door??)

Of course getting the height right is should be an obvious thing as well. (At 65 I don't want to have to do a lot of kneeling to load or clean up the smoker.)

Of course not having a huge budget for the build is another factor for me as well. Those Big Green Eggs are nice but I see a number of limitations beyond capacity with those.

Have I missed anything?

Always open to learn new ideas.

Good friend is a mason and has offered a few items to get things started. Will be asking him for review of my plans and ideas before breaking ground. I do plan on getting a foundation dug and letting a bout 4-6 inches of course lime settle through the winter before I even think about the slab pour. Here in NW Ark. rock will make that dig real fun so during a post freeze wet spell is a good dig time.

________________________________________

Edit on 12/22/14

Looking at various sites for parts such as fire grates and racks for cooking shelve. SOOO many choices but if I can find parts pre-made that fit.... I figure that's one less thing to sweat details on. Finding costs vary quite and bit ($9.00 to $80.00 for steel grills) but by looking at various charcoal and gas factory made units at stores I am finding several that have the parts that should fit my current plans.

Also downloaded a nice 3d Drawing program that even has firebrick objects you can use to 'draw' your design nicely. (SketchUp) This screen grab image is very rough compared to the one is the program. The printed image from the program on a laser printer is very good.

[if gte vml 1]><v:shapetype id="_x0000_t75" coordsize="21600,21600" o:spt="75" o:preferrelative="t" path="m@4@5l@4@11@9@11@9@5xe" filled="f" stroked="f"> <v:stroke joinstyle="miter"/> <v:formulas> <v:f eqn="if lineDrawn pixelLineWidth 0"/> <v:f eqn="sum @0 1 0"/> <v:f eqn="sum 0 0 @1"/> <v:f eqn="prod @2 1 2"/> <v:f eqn="prod @3 21600 pixelWidth"/> <v:f eqn="prod @3 21600 pixelHeight"/> <v:f eqn="sum @0 0 1"/> <v:f eqn="prod @6 1 2"/> <v:f eqn="prod @7 21600 pixelWidth"/> <v:f eqn="sum @8 21600 0"/> <v:f eqn="prod @7 21600 pixelHeight"/> <v:f eqn="sum @10 21600 0"/> </v:formulas> <v:path o:extrusionok="f" gradientshapeok="t" o:connecttype="rect"/> <o:lock v:ext="edit" aspectratio="t"/></v:shapetype><v:shape id="_x0000_i1025" type="#_x0000_t75" style='width:280.5pt; height:228.75pt'> <v:imagedata src="file:///C:\Users\Scott\AppData\Local\Temp\msohtml1\01\clip_image001.png" o:title="" croptop="5243f" cropbottom="3495f" cropleft="13107f" cropright="13107f"/></v:shape><![endif][if !vml]