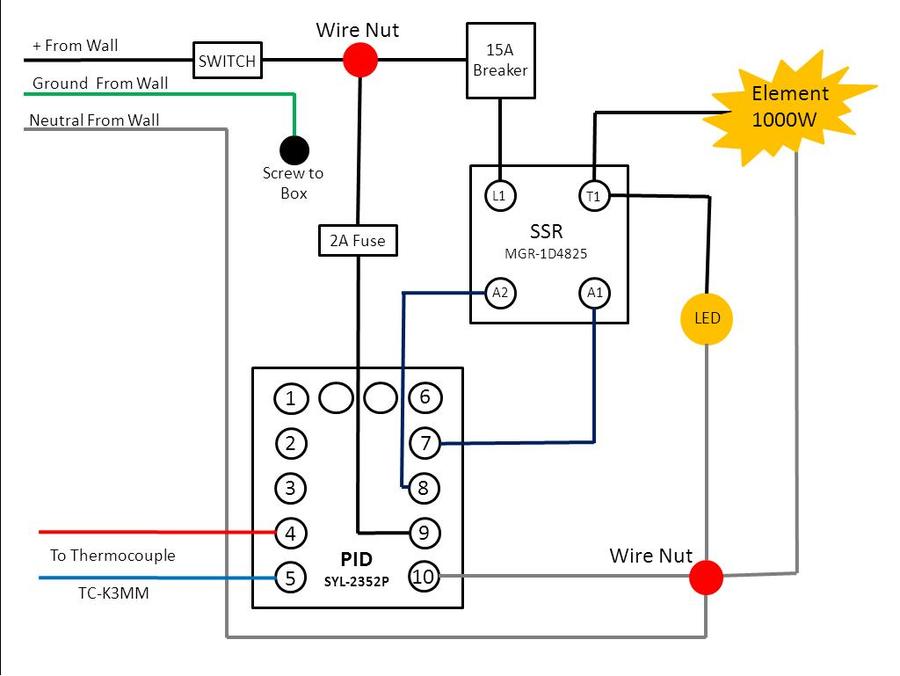

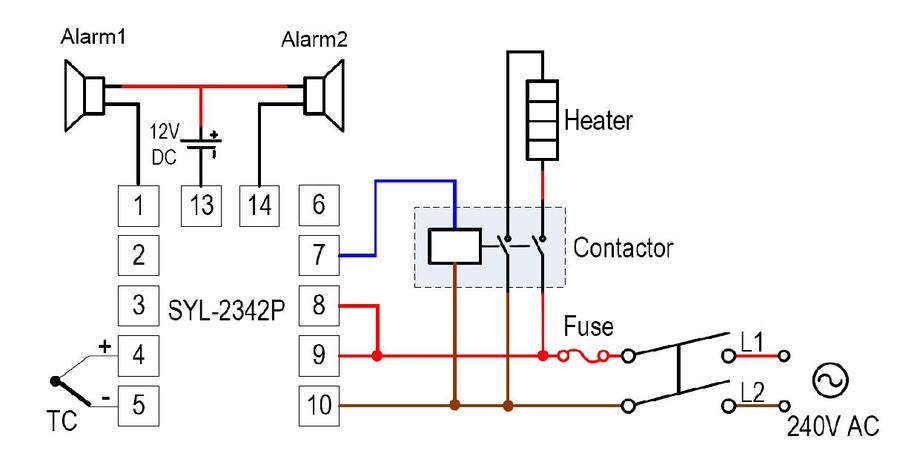

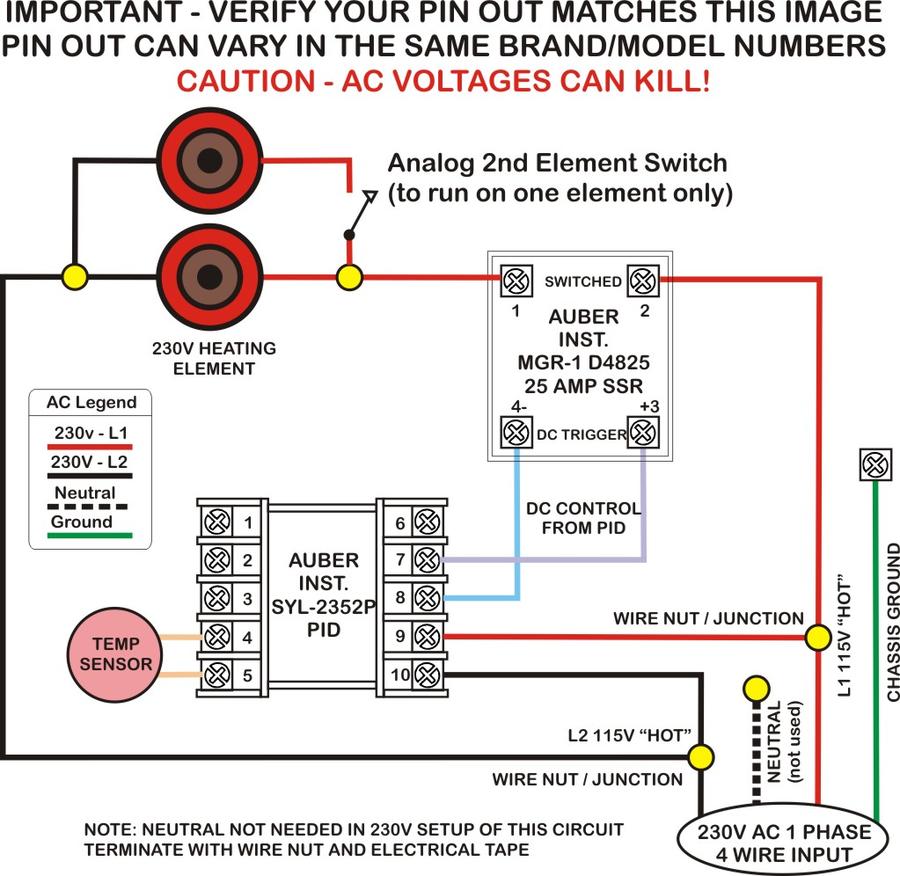

Ok, here is the diagram reworked for the Auber PID and the Auber SSR that Mike listed by part numbers. **STILL DOUBLE CHECK THE PIN OUT MARKINGS ON BOTH DEVICES, IF THEY ARE MARKED DIFFERENT, GO WITH WHAT THE SCHEMATIC ON THE DEVICE SHOWS AS CORRECT**

C A U T I O N ----- 115v and 230v AC circuits can kill. That being said, if you are uncertain of your ability to work with AC voltages, contact an electrician! Safety first....

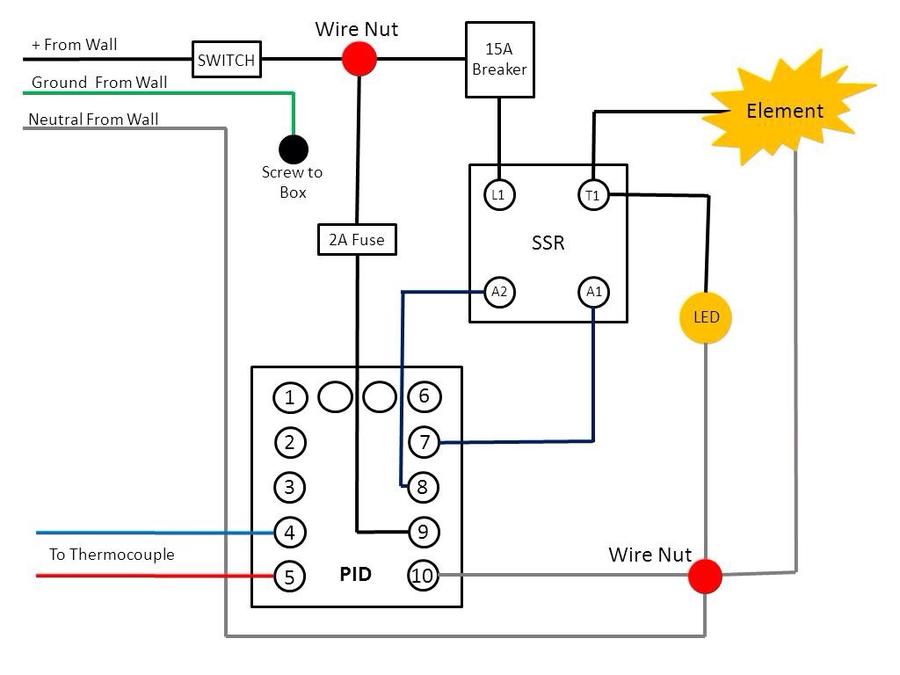

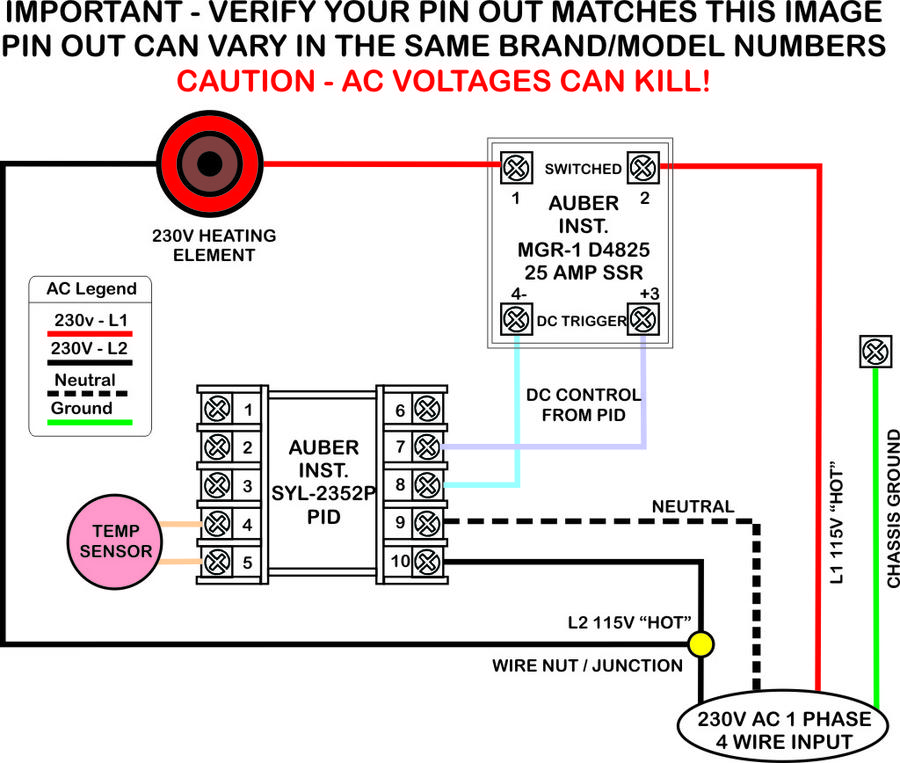

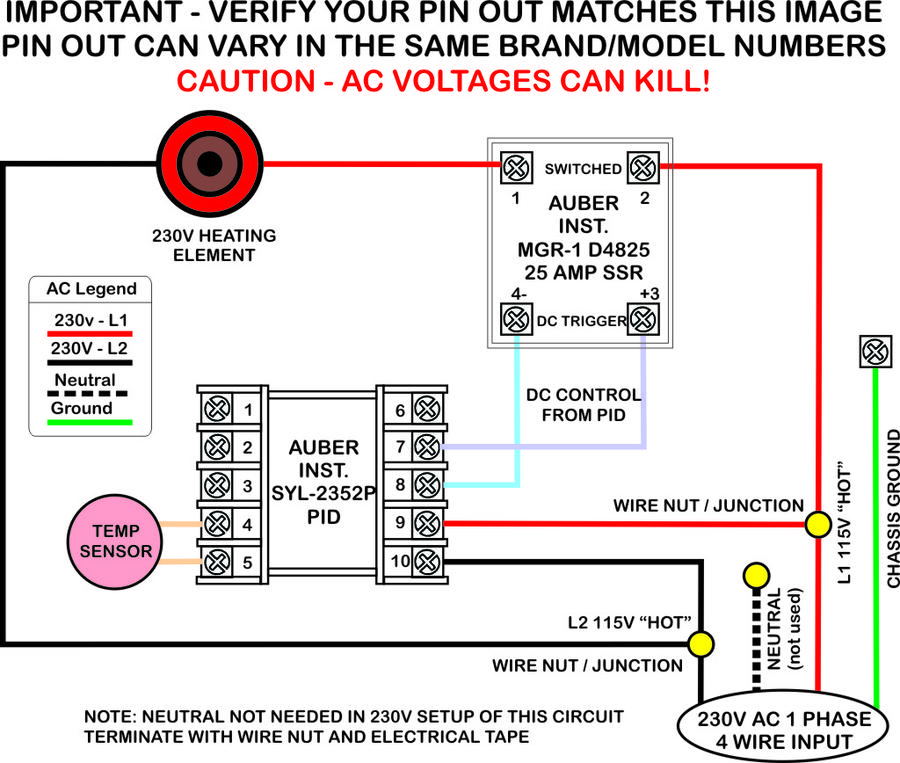

I cleaned up the circuit diagram and reworked it with the Auber Instruments part numbers. Keep in mind that we are working with a single phase 230v AC circuit which is actually two 115v legs. The voltage potential between the L1 and L2 legs is 230v, and the voltage potential between EITHER the L1 and neutral OR the L2 and neutral is 115v. In a purely 230v circuit, the neutral wire is not generally used (it is only used if you need to tap into on of the legs of the 230v for a 115v circuit). I did not show fusing or circuit breakers to keep the circuit simple. I would recommend a fuse/breaker for the PID and if you put a breaker on the 230v supply line, make sure to use a double pole breaker (230v breaker) and not two single pole breakers (115v breakers).

This is the circuit with the PID wired to operate on 115v, and the heating element on 230v.

This version has the PID wired for 230V power. In this version the neutral wire is not used. Just cap it off with a wire nut and wrap the wire/nut with electrical tape to secure it. This version adds an extra wire nut to make the tap into both the L1 and L2 legs to form the 230v voltage path.

As to your question about the wiring gauge needed. That depends on the wattage rating of the heating element you intend on using. That will be the key. HOWEVER! Remember you have doubled the voltage so you have also doubled the wattage you can drive from the same size wire. So a 1,500 watt load will require 13.04 amps at 115v. The same load will require only 6.52 amps at 230v. But it's not as simple as taking a 1,500 watt element and upping the voltage to 230v. The elements are designed to operate on a certain voltage. You need to match the voltage to the element you have. So you cannot take a 1,500 watt brinkmann element and double the voltage to make it a 3,000 watt element. You will probably burn in out very quickly (in seconds) if you try this, so make sure you match the voltage to the actual element you use.

So back to the gauge question.....

A 14 gauge wire is rated for 15 amps at 115v. This same 14 gauge wire can carry the same 15 amps at 230v, but you have doubled the potential load you can power because you doubled the voltage. Load is measured in watts, so you have doubled the potential load wattage from 1,725 at 115v to 3,450 in a 230v circuit on the same 14 gauge wire.

Another thing about wiring and heat. Wiring will start to loose "ampacity", which is the amperage capacity, as temperatures increase. Make sure to use high temperature wire for the section of the circuit that goes inside the cabinet to the heating element. You can find high temperature wire at any appliance repair store, Grainger, or McMaster Carr. Some Home Depot's or Lowe's may also have it. It's generally white in color and has what looks like a woven fabric outer sheath, but that is the insulating material.

Hope this helps......