Last week I bought a used MES40 Gen2 1200 Watt on the cheap ($40) !

I decided I would rewire it and use an Auber PID to replace the controller and I would give the unit to my mother as a gift.

I chose the Auber WS-1510ELPM plug and play PID.

This was my first time using a PID of any kind and rewiring an MES. I didn't know what to expect and reading everyone talk about their Auber PIDs and using the Autotune feature it seemed like it would be a cake walk using the PID.

Here is are my experiences with the Auber WS-1510ELPM and Autotune:

I decided I would rewire it and use an Auber PID to replace the controller and I would give the unit to my mother as a gift.

I chose the Auber WS-1510ELPM plug and play PID.

This was my first time using a PID of any kind and rewiring an MES. I didn't know what to expect and reading everyone talk about their Auber PIDs and using the Autotune feature it seemed like it would be a cake walk using the PID.

Here is are my experiences with the Auber WS-1510ELPM and Autotune:

- Physical setup of the PID was simple. Just plug everything up and turn on

- Configuration setup of the PID was a little more challenging. It is not what I would call user friendly right out of the box BUT once you grasp PID "language" you should find it is actually quite simple. Simply put, when you are talking the same language things make sense.

- The PDF manual comes on disk with the unit. I read through the PDF manual separately from playing with the PID and was quite lost the first time through. It definitely takes playing with the PID and reading the manual at the same time to grasp what the manual is talking about. The order of information vs setting instructions in the manual also seemed backwards to me. I would read about all of these settings and configs but not know where or how I would be setting them until after the information was presented. Very backwards in my opinion, and not always consistently done that way for every section.

My Suggestions:- Plug in the PID in your living room and open up the manual on a computer where you can have both the PID and the manual side by side or you can look back and forth between the two easily.

- Identify the default values listed in the manual before you play with the values. For instance, it already comes configured in Fahrenheit (F) vs Celsius. Don't go trying to set for F since that is the default regardless of the fact that all temperature configuration start with a value of "C". So when you set "C-1" (temp) your numeric value is actually in Fahrenheit (F) even though the configuration label happens to have a "C" in it. This is confusing if you just turn things on and start pressing buttons.

Why didnt they use "t" for temp? Well they use "t" for time, example "t-1" would be the time configuration.

C-1 and t-1 are for "Step 1" temperature and time. - Know that a number of the steps are already pre programed (steps 1-3 I think). Go ahead and change steps 2 - 6 so the temperature is "0" and the time is "0", this will make the steps be ignored according to the manual. Steps 2-6 will be indicated by the labels "C-2" & "t-2", "C-3" & "t-3" ... "C-6" & "t-6".

- Run the Autotune feature so the PID will do all the work configuring it's controller settings (P.I.D. values)

- Set "C-1"(temp) to 275 for max temp of an MES smoker (this is in Fahrenheit because that is the default)

- I set "t-1" (time) to 600 for minutes. I'm not sure this matters with Autotune but I didn't want the time to stop before autotune finished

- Set all other steps temp and time to "0"

- Autotune Lessons Learned:

- It takes a while for Autotune to run, it took like 45 minutes or so for me

- After Autotune completets the temp will drop quickly and by like 30+ degrees. This really confused me because I thought it would just hold when completed. I believe it completely exits autotune and then takes a while to kick back into running as normal

- After the big fast temp drop it will take a while for the temperature to heat up again but it will

- When the temperature heats up it will overshoot the 275F you have programmed in, and mine went over about 8 degrees to 285F. I was confused again thinking it should not have overshot so much and started Googling manual PID configuration because I thought I had an extreme swing going from 248F to 285F. I WAS WRONG

- The temp slowly dropped down to 273F and then smoothly worked up to 275F where it held beautifully for the next hour!

- It seems to me that the drop to 245F was just the system going out of Autotune and then finally starting back up to do it's job normally

- The overshoot to 285F seems like the system just firing up and overshooting a little which is desired from what I read.

- The system them seemed to do it's job and methodically work to 275F and held!

- In short, don't panic and let it do it's thing. Give this about 2hours total to autotune and prove itself

- My Maverick smoker probe temp and my Auber smoker probe temp are at a 5 degree difference with my Maverick being 270F and my Auber probe being 275F

- This seems ok to me as the probes are clipped to the same wires of the rack but the Auber probe is about 3-4 inches away from the Maverick probe. The Auber probe is closer to the back of the smoker and the Maverick probe is closer to the front (door) of the smoker. In my experience the further away from the door the hotter a stove/grill/smoker will get so the temp difference seems to make sense

- Pulling off and re installing the Gen 2 back panel was a pain. It did not come all the way off but I got it loose up to the top where the smoker handle is fastened. I removed the handle but those rivets for screwing in the handle to the smoker did not want to budge so I just rolled he metal back. The edge of the sheet metal back goes into a groove of the smoker body and was problematic. When you remove the sheet metal back that inserted edge of the metal bends and crinkles up. You then have to try and form it back into shape when reapplying the sheet metal back. A hammer, some needle nose plyers, and patients were needed. In the end I got it back on in an acceptable manner and then put some sheet metal screws through the sheet metal backing into the frame of the smoker to hold it all in place well.

- I ran the Auber smoker temp probe through the same fixture that the Gen 2 uses for it's meat probe. This took a little effort and ingenuity but worked. I just took a large screw driver to punch through the insulation to make a channel the new probe could easily move through. I then taped the new probe to the old MES probe and pulled the old MES probe through the hole and channel like fishtape. Viola a moveable smoker temp probe that seems like it was stock installed!

- I swapped the existing snap disk/rollout temp limit cuttoff switch for a reset-able one. I also used a switch rated to 350F because I had no idea what the old one was actually limited at and I didn't know how the autotune of the Auber PID would temp swing and didnt want to pull everything apart again to change the snap disk/rollout. BEWARE the new temp limit if you follow in my footsteps here, you have been warned. It was a perfect fit with no issues!

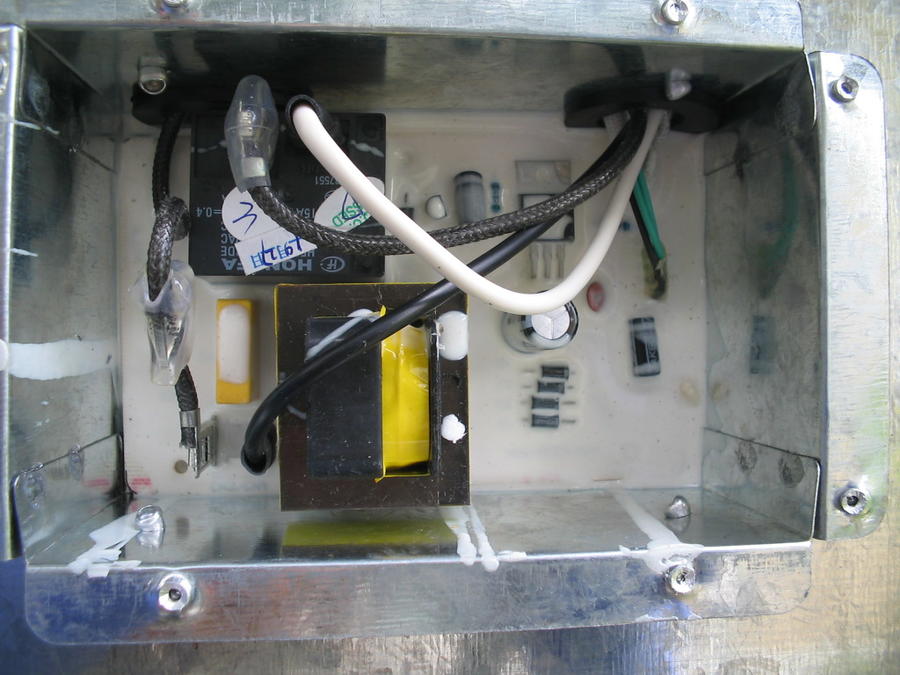

- I rewired the MES to basically go from chord to heating element. The only thing I made sure to do was to wire the hot wire of the MES chord into the snap disk/rollout limit temperature sensor so it is included for safety reasons. I didn't want to leave out a safety measure ESPECIALLY when the new wiring changes go directly from chord to heating element.

- I switched out aluminum connectors with high temp steel connectors to the snap disk/rollout and the heating element. Also used a high temp steel butt connector/splice to connect the hot wire to the snap disk/roll out wiring. I bought them from "Fry's Electronics", online was outrageous in price and did not offer much in variety (spade vs ring vs butt, etc.).

- I used high temp plastic shrink tube over any and every exposed connector or wiring splice. I used my butane grill lighter to carefully shrink the tubing because I don't have a heat gun. I bought them from "Fry's Electronics" and it was way cheaper than online options. Like $1.50 vs $5-$10 online.

- I used all existing 14 gauge wire and a 14ga extension chord to be consistent with all of the wiring in the existing MES system. I was tempted to go to 12 gauge but I didn't want to risk inconsistency in the wire capabilities and amperage limits within the system.

- I pulled all old wires out of the system and cut the wires to the existing MES smoker probe.

- I completely removed the old MES top/front controller

- I replaced insulation with some high temperature stove/oven insulation I bought off ebay. The snap disk/rollout wires were burried under the foam insulation and to get to them you have to cut all the way through the insulation as they are pinned to the body on the opposite side. This left a channel all the way down to the bare metal of back side of the smoker's interior smoking chamber. I wrapped the wires in the stove/oven insulation and filled the channel well so there were no gaps without insulation

- In all the disassembly, rewire, and reassembly took about 8 hours with the proper tools, a great and confident amount of research, and zero experience in ever doing something like this

![DSC_8887[1].JPG](/media/dsc_8887-1-jpg.512967/full?d=1507243730)

![DSC_8888[1].JPG](/media/dsc_8888-1-jpg.512968/full?d=1507243730)