I think my vent is about 70% or more closed. It's pretty stuck and I can only move it once it's hot since that unsticks it some lol. I don't think half open would hurt anything, just don't close it way down.I was going to ask how in the world you're getting accurate temps where the food is if your probe is right above the element. But the wood sheet kind of answered that, I guess. That's actually what my problem was - my probe was on the bottom rack, but by my meat was in the middle and ~50f less. I didn't flip my element, but I did put an exhaust dead center on the top and it was wide open the whole time. Maybe I should try half open?

Do you put a drip tray above or below your element? I had a tray on the bottom most rack with the probe underneath. Maybe the tray was reflecting heat back on the probe?

Similar to dr k's setup I have a foil pan on the bottom rack which protects the heating element. I put a V shaped rack or I just set an MES smoker rack on top of my pan and put the meat on the rack so it's only elevated a little bit from the lower rack's level.

This is what it looks like but these days I just use a MES rack instead of that copper looking rack on the foil pan.

The foil pan would be sitting on my lowest rack in the MES and protects my heating element.

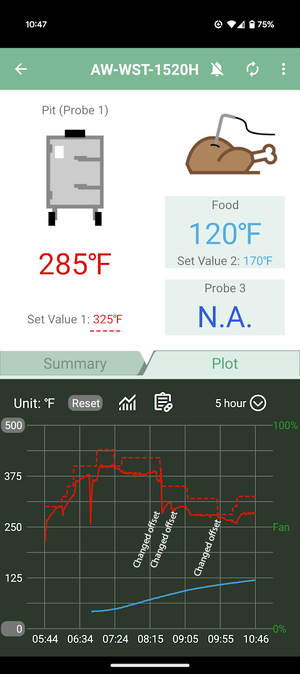

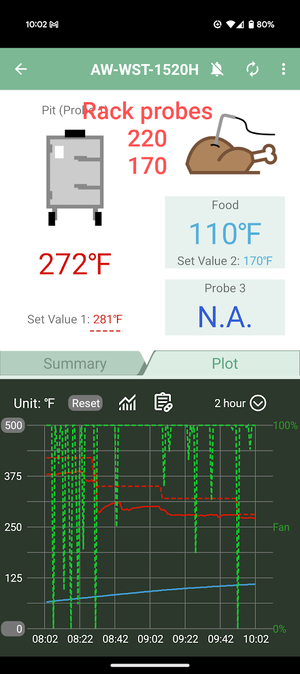

I think your probe and pan are ok but 225F measured at the lowest rack will definitely be closer to 200F at a higher rack. My little board mod to reduce volume helps to trap that heat below without it just having a free path to sprint out the vent. I think if you want to continue your configuration you leave the PID temp prove where you have it and just make sure to have another probe at meat rack level and then just crank up the set temp until your meat rack level is getting 225F.

Just be sure you aren't running over 325F at the lower part of the smoker and if running 325F don't go over 4 hours at that temp. It can handle 4 hours at 325F but the insulation isn't rated to continuously work at temps like that forever.