I appreciate this group and how helpful everyone has been. You all have provided me great advice and assitance. I performed the simple switching of the connectors and she is heating right up with my new PID controller. Appreciate it, looking like Easter ham is back in the smoker. Cant thank you all enough!

MES Rewire Simple Guide - No Back Removal Needed!!!

- Thread starter tallbm

- Start date

-

Some of the links on this forum allow SMF, at no cost to you, to earn a small commission when you click through and make a purchase. Let me know if you have any questions about this.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Glad to hear you are up and running! Have a wonderful Easter and Easter ham :DI appreciate this group and how helpful everyone has been. You all have provided me great advice and assitance. I performed the simple switching of the connectors and she is heating right up with my new PID controller. Appreciate it, looking like Easter ham is back in the smoker. Cant thank you all enough!

Me MES30 wiring/circuitry looks different, not sure if this is now what they use or I got some odd model, so I'm unsure how mine would be wired so I can use my new Auber WS-1510ELPM.

Edit: Found someone else with a similar setup, page 15. Looks like I just need to follow the rule of "smooth power to color braided" and do either black/blue and white/red, or black/red and white/blue, since AC has no polarity meaning it doesn't matter here?

Edit: Found someone else with a similar setup, page 15. Looks like I just need to follow the rule of "smooth power to color braided" and do either black/blue and white/red, or black/red and white/blue, since AC has no polarity meaning it doesn't matter here?

Attachments

Last edited:

Hi there and welcome!Me MES30 wiring/circuitry looks different, not sure if this is now what they use or I got some odd model, so I'm unsure how mine would be wired so I can use my new Auber WS-1510ELPM.

Edit: Found someone else with a similar setup, page 15. Looks like I just need to follow the rule of "smooth power to color braided" and do either black/blue and white/red, or black/red and white/blue, since AC has no polarity meaning it doesn't matter here?

Correct. Go Black smooth to braided and white smooth to braided and you will be good. No polarity :D

Let us know how it works out :D

monkman911

Newbie

- Jul 7, 2024

- 8

- 8

Awesome article, my MES just fell victim to the runaway heating issue. I have a PID headed my way but not sure how to wire that in the existing wiring. Any help would be greatly appreciated!Lately I've seen a number of posts about guys wanting to rewire their MES. I had wanted to post a quick and simple guide for those out there that are curious or those that simply need to rewire but need a little assistance. Well here goes.

Disclaimer: When messing with electrical equipment it is best to consult a local electrical professional to ensure things are done correctly. Be safe and use caution. I am not an electrician and with many things you hear or read, it is your responsibility to verify the information's validity and ensure you and others are safe.

Ok now on to rewiring info :)

Smoker Referenced Below:

Tools and Equipment (at a Minimum):

- MES 40 Gen1

- A strong back or a 2nd body to help pick up the smoker and set on a table to be worked on

- Waist High Table - to put the smoker onto

- Needle Nose Plyers

- Wire Crimping Tool - one that crimps, strips, and cuts wires

- 14-16 AWG Butt Connectors, or Wire Nuts

- Drill

- 1/8" Drill Bit that can drill metal - to drill out circuit board rivets

- #12 - 1" self tapping Sheet Metal Screws/Fastener to refasten circuit board panel back on after rivets are removed. 3/4" long may also be good for this one panel but MAY be a little short. I used 3/4" because that is what I used when pulled the back off my MES

- Drill Bit to drive the sheet metal screws (I used hex head fasteners but you may find hex + phillips head)

- Masking Tape/Electrical Tape - some kind of tape that can be used to mark a wire. U need no more than 1 inch worth

Quick Explanation of the Process:

The rewire is actually very simple and does NOT require removing the back of the MES. What is being done is the following:

When done, the MES controller will be bypassed and will receive no electricity. Also the safety mechanism (safety roll out limit switch) will still do it's job and cut off power to the heating element should the heat limit be exceeded. The switch will auto reset after a while and when it does electricity will again be able to flow to the heating element.

- Take existing MES wiring and disconnecting it from the MES circuit board the controller is connected to

- Connect Hot wire that comes from MES plug, to Hot wire that leads to the safety Roll out Limit Switch & Heating Element

- Connect the Neutral wire that comes from the MES plug, to the Neutral wire that leads to the Heating element

- Done!

IMPORTANT: If you plug the rewired MES into the wall there is NOTHING to control the electricity to the element. If plugged in, the MES will simply just suck electricity and heat up as a dumb circuit. This is why a 3rd party controller like a PID controller is needed.

The PID controller will control the on/off flow of electricity to the heating element according to the set temperature and the temp the PID controller is reading with a probe from within the smoker.

Simple Rewire Steps:

The process should really take between 30 minutes and 2 hours based on how you work, preperation, and confidence/comfort level with the tools and the process.

Well that is it. This approach is about as simple as it gets to rewire a Gen1 MES. Now every MES generation and model may be a little different but the idea for rewiring is still the same.

- UNPLUG the MES!!!!

- Get the MES up on a table laying flat on it's back or on the front. If you lay it on the front (what I did) be sure not to break the glass window in the door... just use caution

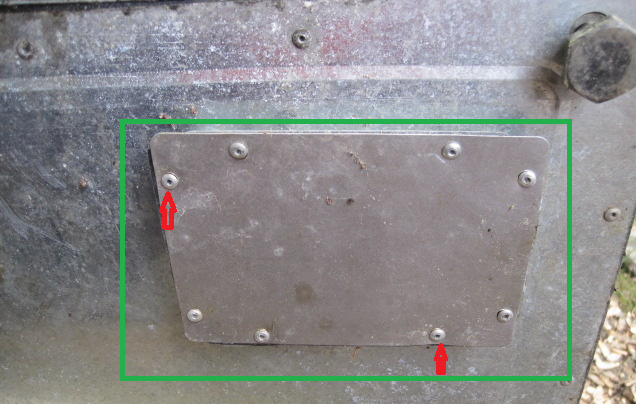

- Using the 1/8" drill bit and a drill, drill out the rivets on the bottom panel of the MES.

The bottom panel is identified by the green square, everything outside of the green square is irrelevant for this step.

The red arrows identify some rivets on the PANEL. ONLY drill out the panel rivets inside the green square, NOT the rivets outside the green square.

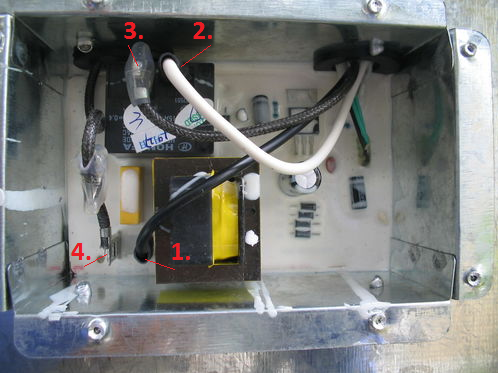

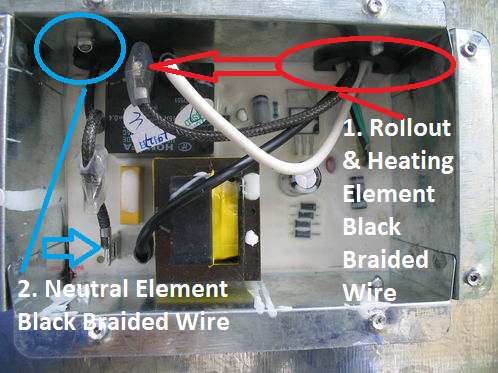

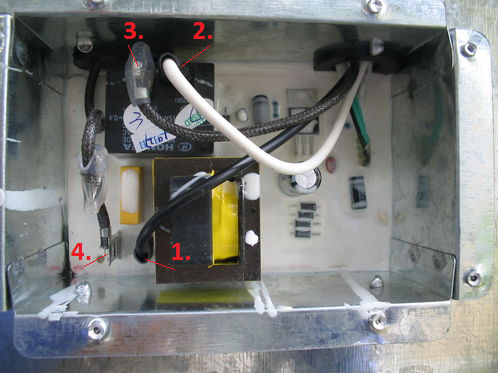

- You should see an image similar to the one below but it may be slightly different. Don't worry if it is slightly different because we will be able to easily identify the wires.

- Use your hand or the Needle Nose Plyers to disconnect the wires listed below:

- Plug Hot Wire - Smooth Black color wire

- Plug Neutral Wire - Smooth White color wire

- Rollout Limit Switch & Heating Element Hot Wire - Black Braided wire

- Heating Element Neutral Wire - Black Braided wire - yes looks just like wire #3

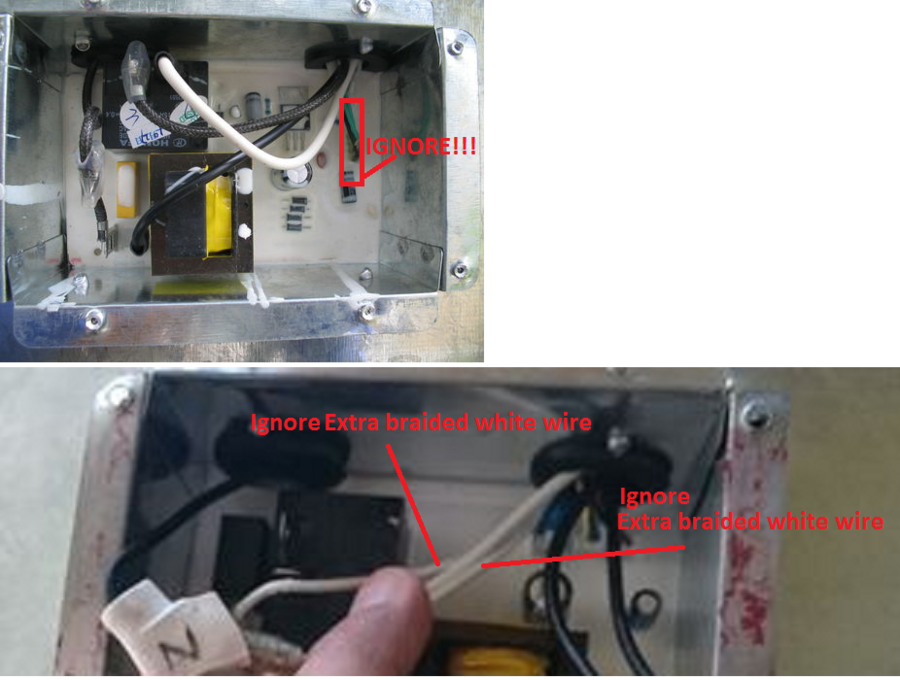

- IMPORTANT: Ignore any other tiny wires that may come out of the upper right hole of the compartment. These can be any color (black, green, white, white braided wire, etc.). They will be noticeably thinner than the real wires!

- Identify and use a piece of tape Label the black braided wires:

- Heating Element NEUTRAL Black Braided wire - Comes out of upper LEFT hole

- Rollout Limit Switch & Heating Element HOT Black Braided wire comes out of the upper RIGHT hole

The key here is to identify the hole that the wire comes out of. Use a piece of tape to flag the wires for quick identification. If you accidentally splice the wires it should be OK and all should still work safely and fine. The thing is the wiring is not TECHNICALLY accurate which may lead to some confusion about which wire goes where.

- Cut and splice wires together. Use butt connectors, wire nuts, or any electrical connectors to splice the wires. JUST BE SURE that the connections are tight!!! You want no wiggle between the connection because that causes resistance and resistance causes heat and that will burn up the wire, wiring, etc. which is bad!

- Connect wires #1 and #3. Notice they should both come out of the upper right hole/port.

- Connect wires #2 and #4. Notice the white wire comes out of the upper right hole/port and the black braided wire comes out of the upper left hole/port. The pic is bad so I tried to erase extra wires and used a Green line to trace the wire and connections. I hope it gives the proper visual.

- When all wired up it should look like the image below:

- Use the sheet metal screws to fasten the panel back on through the rivet holes.

- Safely put the smoker back on the ground

- Open the smoker door and plug in the MES to the wall outlet. You should feel that it is heating and if you leave it on long enough you will see the element start turning color showing heat.

Additional Rewire Considerations:

This post is simply showing how to rewire for a 3d party controller to be used, BUT it does not address some week points of the MES wiring. I will note some improvements that should be considered because they are common issues with the MES that you will likely run into an need to fix at some point.

Best of luck guys and remember to be safe and enjoy smoking! :)

- Replace the Heating Element connectors with Hi Temp Stainless Steel female spade connectors - the MES uses poor electrical connectors on the wires that connect to the heating element. They don't seem to be able to stand up to the heat of the element very well and corrode easily. Mine showed signs of corrosion after 3 months of use!!! Google the following connectors as good replacement options:

Supco T1111c (typical female spade), or Supco T1113c (flag style female spade)

Again, be sure the connectors are on completely and are crimped complete! You want NO wiggle. Keep working until you get the proper connection.

- Replace the Safety Rollout Limit Switch connectors with Hi Temp Stainless Steel female spade connectors - as stated above the connectors that MES uses are poor and corrode easily. The connectors here suffere the same issue.

The big issue is that most MES smokers do not have a panel to access the rollout limit switch. In this case, you must remove the back of the MES to get to the rollout limit switch

- Consider cutting and creating a panel to access this switch in the future

- The rollout limit switch is a little delicate so if you happen to damage it go to Amazon and search for: KSD301 for replacement switches should you knock a tab loose or bend it or damage it in any way.

Again, be sure the connectors are on completely and are crimped complete! You want NO wiggle. Keep working until you get the proper connection.

Hi there and welcome!Awesome article, my MES just fell victim to the runaway heating issue. I have a PID headed my way but not sure how to wire that in the existing wiring. Any help would be greatly appreciated!

Let us know exactly what you bought (amazon links would be great).

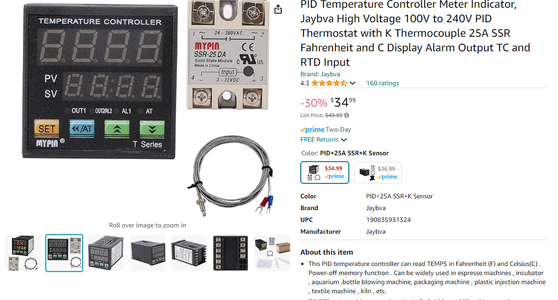

if you but just a PID controller that looks like this, there is a lot more involved than just wiring it into the MES. You would have to buy more parts, components, etc. to build a fulling working PID controller. This part is the main piece but not the only piece:

A ready to completely built PID controller that can handle any MES would be this one from Auber:

Multi Purpose Controller [WS-1510ELPM] - $159.95 : Auber Instruments, Inc., Temperature control solutions for home and industry

Auber Instruments, Inc. Multi Purpose Controller [WS-1510ELPM] - The WS-1510ELPM is a versatile temperature controller to have in your home. It can be used for various applications such as Sous Vide cooking, controlling an electric smoker, making yogurt, dough proofing, controlling the...

www.auberins.com

It runs about $160 normally but the last day of their 4h of July sale is today 7/7 and they have it $10 off.

If you've never built a full PID controller before then you won't really save any money building the 1st one ever due to cost of buying parts, components, and any tools necessary. If you build more than 1 then you get some savings on controllers 2+ due to having additional components and tools already in hand.

Ask all the questions you have and I'm positive we can get you up and running :D

monkman911

Newbie

- Jul 7, 2024

- 8

- 8

Thank you for the quick reply Tallbm! I did indeed get one of the cheap PIDs. I'll return it and grab an Auber. I'll post again when that one shows up. https://www.amazon.com/gp/product/B07XNQ538P/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&th=1Hi there and welcome!

Let us know exactly what you bought (amazon links would be great).

if you but just a PID controller that looks like this, there is a lot more involved than just wiring it into the MES. You would have to buy more parts, components, etc. to build a fulling working PID controller. This part is the main piece but not the only piece:

A ready to completely built PID controller that can handle any MES would be this one from Auber:

View attachment 700122

(the multi purpose probe version)Multi Purpose Controller [WS-1510ELPM] - $159.95 : Auber Instruments, Inc., Temperature control solutions for home and industry

Auber Instruments, Inc. Multi Purpose Controller [WS-1510ELPM] - The WS-1510ELPM is a versatile temperature controller to have in your home. It can be used for various applications such as Sous Vide cooking, controlling an electric smoker, making yogurt, dough proofing, controlling the...www.auberins.com

It runs about $160 normally but the last day of their 4h of July sale is today 7/7 and they have it $10 off.

If you've never built a full PID controller before then you won't really save any money building the 1st one ever due to cost of buying parts, components, and any tools necessary. If you build more than 1 then you get some savings on controllers 2+ due to having additional components and tools already in hand.

Ask all the questions you have and I'm positive we can get you up and running :D

Thank you again for the help!

Attachments

Last edited:

I'm glad the info helped!Thank you for the quick reply Tallbm! I did indeed get one of the cheap PIDs. I'll return it and grab an Auber. I'll post again when that one shows up. https://www.amazon.com/gp/product/B07XNQ538P/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&th=1

Thank you again for the help!

That PID "kit" seems fine but it is not a complete PID controller.

You would have to still get a good number of components, a enclosure, and do a little fabricating on the enclosure to make everything install and fit together to make a complete controller.

It's a fun project but not something that is going to save you time or money if just building one in your life and if you just want to get up and running.

Once you do the simple MES rewire the Auber will be plug and play with the addition of changing the P-I-D values to some tries and true ones that members here use:

Here is a good thread on all your Auber settings and functions because their manual was written by a drunk illiterate person... so it seems hahahah :D

Setting Auber PID Temp, Time, and Other Values

This has come up numerous times so I figured I would try and write a simple "how to" for doing Auber PID time, temp, and P-I-D settings. Auber makes a great PID, however their documentation and instructions are technical and also likely written by someone that isn't very strong with organized...

P=7, I=208, D=210 seem to be good values for an Auber and an MES (for quick reference).

Let us know how it goes and if you have any questions :D

Hi tallbm!

tallbm is correct. The PID controller is a kit that comes with a controller, a solid state relay, and a heat sink for the relay. YOU have to come up with a case or box to install it, an on and off switch, and then wire it up. From there you have to install it on the MES and wire it up.

If you like wiring projects and have the time it is not too overly difficult. I did it with pictures on this thread back a few pages. The programming wasn't too hard. In the end I think it cost me about 80 bucks, and my time to make it and hook it up.

It works great! I did a brisket last week that was incredible! I still want to do one more modification to add a switch-controlled LED light. I calibrated the oven temp to the controller followed by some auto-tuning and have it dialed in nicely.

Thinking about trying some slow cooked old fashioned sloppy/messy barbque chicken next week. If you want to get up and running quickly, tallbm is giving the correct advise!

tallbm is correct. The PID controller is a kit that comes with a controller, a solid state relay, and a heat sink for the relay. YOU have to come up with a case or box to install it, an on and off switch, and then wire it up. From there you have to install it on the MES and wire it up.

If you like wiring projects and have the time it is not too overly difficult. I did it with pictures on this thread back a few pages. The programming wasn't too hard. In the end I think it cost me about 80 bucks, and my time to make it and hook it up.

It works great! I did a brisket last week that was incredible! I still want to do one more modification to add a switch-controlled LED light. I calibrated the oven temp to the controller followed by some auto-tuning and have it dialed in nicely.

Thinking about trying some slow cooked old fashioned sloppy/messy barbque chicken next week. If you want to get up and running quickly, tallbm is giving the correct advise!

monkman911

Newbie

- Jul 7, 2024

- 8

- 8

The Amazon PID showed up today and I'll return that tomorrow. The Auber should be here tomorrow also. In the meantime I can probably start on the rewire. I have an MES30, along with a Traeger and an Oklahoma Joe barrel smoker. Each has their pros and cons but I can't do without my MES for doing my mac and cheese recipe :-). I see above that the rewire for the MES30 is basically the same as the 40?

Thank you for your patience!

Thank you for your patience!

monkman911

Newbie

- Jul 7, 2024

- 8

- 8

Page 15 of this thread gives me everything I need for the rewire. I am assuming the connector on the Auber will plug right into the MES connector on top?The Amazon PID showed up today and I'll return that tomorrow. The Auber should be here tomorrow also. In the meantime I can probably start on the rewire. I have an MES30, along with a Traeger and an Oklahoma Joe barrel smoker. Each has their pros and cons but I can't do without my MES for doing my mac and cheese recipe :-). I see above that the rewire for the MES30 is basically the same as the 40?

Thank you for your patience!

Thank you!

I'm a little confused but I'll try and answer lol.Page 15 of this thread gives me everything I need for the rewire. I am assuming the connector on the Auber will plug right into the MES connector on top?

Thank you!

When you rewire the MES you will plug the MES plug into the Auber, it has an outlet on it.

You will then plug the Auber into your wall outlet.

You will drop the Auber temp probe down the MES vent and clip underneath the lowest rack in the center to measure smoker temp.

You will enter your set temp into the Auber.

Now the Auber will take power from the wall and feed it to the MES plug which feeds it to the heating element because of the MES rewire job. The Auber will cut power on/off to the MES until it hits and holds the set temp.

No part of the Auber will connect to any part of the MES except for the MES plug into the Auber.

There were a lot of pictures on page 15, so let me know if this info helps hahaha :D

Page 15 of this thread gives me everything I need for the rewire. I am assuming the connector on the Auber will plug right into the MES connector on top?

Thank you!

It's actually much simpler than that.

You're rewiring your MES to bypass its controller and basically turn it in to an always-on heater. This effectively disables/isolates the OEM controller on your MES. I removed mine and tucked its cable down in to the hole it comes out of on my MES.

You're then plugging your MES power cord in to the back of the Auber, and plugging the Auber in to the wall. The smoker will no longer plug directly in to a wall outlet, because it will just continue to heat until it triggers the safeties/sensors in it.

The Auber decides, via its temp probe and PID settings, when to turn your smoker on or off. It is far more accurate and reliable than the OEM controller/sensor.

monkman911

Newbie

- Jul 7, 2024

- 8

- 8

Sorry for the confusion guys! When I read "plug and play" my computer mind jumped to the Auber plugging into the MES via the 4 lead connector. I did the rewire on the MES which is a model 20071814, plugged it in, and heated up with no circuit breakers popping. Here is a photo of the wires I connected. The Auber should be here later today and then I can start tuning.

Thank you again guys for all of the help!

Thank you again guys for all of the help!

Attachments

Congrats!!! When the Auber get's there you will be just about good to go. A little Auber setup, tweaking, and boom amazing smoker!!!!Sorry for the confusion guys! When I read "plug and play" my computer mind jumped to the Auber plugging into the MES via the 4 lead connector. I did the rewire on the MES which is a model 20071814, plugged it in, and heated up with no circuit breakers popping. Here is a photo of the wires I connected. The Auber should be here later today and then I can start tuning.

Thank you again guys for all of the help!

monkman911

Newbie

- Jul 7, 2024

- 8

- 8

Thank you sooo much once again, I was devastated when the MES failed, I really do like the smoker and now I'm back in business!Congrats!!! When the Auber get's there you will be just about good to go. A little Auber setup, tweaking, and boom amazing smoker!!!!

monkman911

Newbie

- Jul 7, 2024

- 8

- 8

The Auber just arrived and before I possibly break it, I do have some questions.Thank you sooo much once again, I was devastated when the MES failed, I really do like the smoker and now I'm back in business!

1. Is it alright to program it without the thermocouple plugged in or do you need to plug it in?

2. Based on the step by step instructions for setting the P-I-D, it looks like you have to do this every time you cook?

3. They sent me a thumbdrive but the bag is in Chinese/Japanese, is this important or just a gift?

Thank you guys, I plan on smoking this weekend!

Nice it's in!!!The Auber just arrived and before I possibly break it, I do have some questions.

1. Is it alright to program it without the thermocouple plugged in or do you need to plug it in?

2. Based on the step by step instructions for setting the P-I-D, it looks like you have to do this every time you cook?

3. They sent me a thumbdrive but the bag is in Chinese/Japanese, is this important or just a gift?

Thank you guys, I plan on smoking this weekend!

1. I think it's fine to program without the thermocouple plugged in as long as it lets you

2. You will only have to set the P-I-D values once. It will also remember your last set temp.

3. The thumb drive just has the manual PDF file on it, you won't need it if you follow the instructions in that post on how to set temp or PID values and such. The manual is very confusingly written hahaha.

I hope it's all going well!

Ain't that the truth!The manual is very confusingly written hahaha.

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Similar threads

- Replies

- 22

- Views

- 7K

- Replies

- 6

- Views

- 4K

- Replies

- 4

- Views

- 4K

SmokingMeatForums.com is reader supported and as an Amazon Associate, we may earn commissions from qualifying purchases.

Hot Threads

-

Featured First Smoked Chili

- Started by mneeley490

- Replies: 19

- Chili, Soups, and Stews

-

First go on making bacon

- Started by Blue Collar Pit Boss

- Replies: 13

- Hot Smoked Bacon

-

Not Sure What To Call It?!

- Started by Rafter H BBQ

- Replies: 10

- Blowing Smoke Around the Smoker.

-

Oscar is rolling smoke today

- Started by irvin78787884

- Replies: 9

- General Discussion

![DSC_0303[1].JPG](/media/dsc_0303-1-jpg.528634/full?d=1507244980)

![DSC_0302[1].JPG](/media/dsc_0302-1-jpg.528632/full?d=1507244980)