Hey guys, Im new here, located in south Louisiana along gulf coast, this is my first post on this forum. I have scoured the net and youtube looking the answer to my problem but as of yet, to no avail. In my efforts I came across this site and thought I would ask yall for some assistance, as MB support sux as most of us know and its all over the net. I have a Masterbuilt MB25071217 with the digital controller. Ive had this unit for 2 yrs, no problems, until now.

Unit was working perfectly, then Hurricane Laura hit the La coast. I went to take it out to smoke a ham for Thanksgiving and nothing. No heat. Everything appears to be in working order but the unit never heats up. Turn on the panel, set the temp, set the time, you can hear to equipment engage with an audible click ( as always) but no heat. My first searches of the net yielded that i need to check continuity of the element. Both from terminal to terminal and from terminal to element exterior. The terminal to terminal check out fine but the terminal to exterior did not. I was getting some continuity with that check. Okay, element is bad.

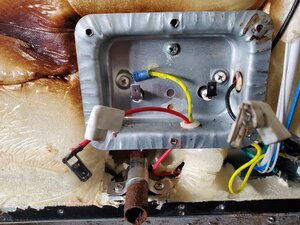

Upon inspection it does appear that the ceramic insulator on one of the terminal ends has separated. Okay, thats my problem. Try to order a new element from MB, no go. Out of stock. Hello Amazon. Find a replacement element , ordered it, it came in this week. Today i go to perform the swap. Still no heat. Everything as before. It all appears to be in working order, but no heat. I take my meter and check the voltage feeding the element. When the unit turns on it only generates 15-18 v feeding the element.

I know this is a 120v unit, but that doenst necessarily mean that it sends 120v to the element, or does it? Should the element see the full 120v from the control panel? I have searched and searched and i cannot find what the voltage output of that panel is, e.g. what voltage is required for the element to work properly. If it required 120v, then obviously ive got a problem somewhere with a what i would assume would be a relay located somewhere on the unit that should feed full 120v power, but isnt.

Just food for thought and to be transparent, this unit stays under cover and out of the direct elements, but when a hurricane comes along those elements tend to go in all directions. There was evidence of wind blown rain and dirt on the side of the unit that i cleaned prior to trying to use. Even though there is no evident short as everything appears to be in working order, as in there are no beeps or other abnormalities with the controller, where else could i look to find my issue? I have not taken the back panel off yet, that was my next step. Thanks in advance for any assistance.

Unit was working perfectly, then Hurricane Laura hit the La coast. I went to take it out to smoke a ham for Thanksgiving and nothing. No heat. Everything appears to be in working order but the unit never heats up. Turn on the panel, set the temp, set the time, you can hear to equipment engage with an audible click ( as always) but no heat. My first searches of the net yielded that i need to check continuity of the element. Both from terminal to terminal and from terminal to element exterior. The terminal to terminal check out fine but the terminal to exterior did not. I was getting some continuity with that check. Okay, element is bad.

Upon inspection it does appear that the ceramic insulator on one of the terminal ends has separated. Okay, thats my problem. Try to order a new element from MB, no go. Out of stock. Hello Amazon. Find a replacement element , ordered it, it came in this week. Today i go to perform the swap. Still no heat. Everything as before. It all appears to be in working order, but no heat. I take my meter and check the voltage feeding the element. When the unit turns on it only generates 15-18 v feeding the element.

I know this is a 120v unit, but that doenst necessarily mean that it sends 120v to the element, or does it? Should the element see the full 120v from the control panel? I have searched and searched and i cannot find what the voltage output of that panel is, e.g. what voltage is required for the element to work properly. If it required 120v, then obviously ive got a problem somewhere with a what i would assume would be a relay located somewhere on the unit that should feed full 120v power, but isnt.

Just food for thought and to be transparent, this unit stays under cover and out of the direct elements, but when a hurricane comes along those elements tend to go in all directions. There was evidence of wind blown rain and dirt on the side of the unit that i cleaned prior to trying to use. Even though there is no evident short as everything appears to be in working order, as in there are no beeps or other abnormalities with the controller, where else could i look to find my issue? I have not taken the back panel off yet, that was my next step. Thanks in advance for any assistance.