I wanted to monitor the IT of what I have on my rotisserie, so to the shop and a day's work. The shaft on the Weber roto was too short, so I substituted one from a generic roto. Excuse the crappy cell phone pictures.

Started with a brass bushing from the hardware store, drilled, tapped, and put in a thumb screw to secure to the shaft.

Enlarged the hole in the roto ring and cut a slot to fit the bushing.

Bushing in place for test fit.

Drilled and tapped a hole in the shaft, ran a screw all the way to hold the thumb screw.

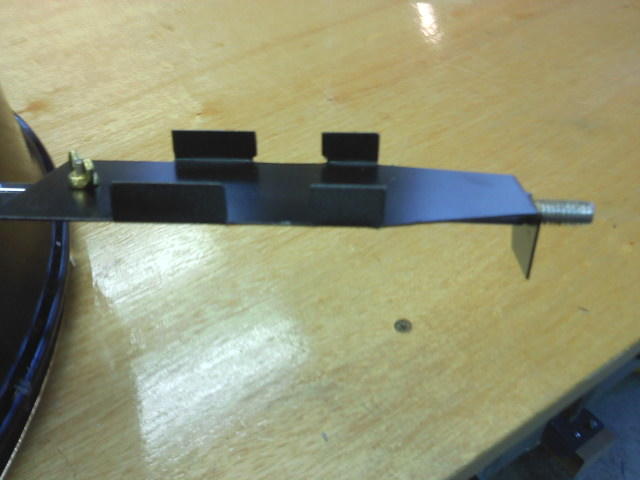

Spent most of the day measuring, cutting and bending the bracket. Bracket is aluminum.

Bracket goes through the end of the shaft.

Bracket in place.

Assembly in place with a velcro strap to hold ET732 in place.

And there we have it. Works very well. Mission accomplished.

Started with a brass bushing from the hardware store, drilled, tapped, and put in a thumb screw to secure to the shaft.

Enlarged the hole in the roto ring and cut a slot to fit the bushing.

Bushing in place for test fit.

Drilled and tapped a hole in the shaft, ran a screw all the way to hold the thumb screw.

Spent most of the day measuring, cutting and bending the bracket. Bracket is aluminum.

Bracket goes through the end of the shaft.

Bracket in place.

Assembly in place with a velcro strap to hold ET732 in place.

And there we have it. Works very well. Mission accomplished.

Last edited: