Hello all,

My name is Matt, I'm 48, Dad to two phenomenal Daughters, and I live/survive in California (trust me, I'm not bragging on the Cali thing). I am self employed as a countertop contractor, so that means I have a lot of free time on my hands.. I also work on boats, hot rods and lots of other manly things. I have worked with my hands since grade school, My Dad was a General Contractor and would pull my brothers and I out of school to work with him. His words to the teachers were "you ain't teachin him $#*! anyway"!!! Although I consider myself a Professional builder of things, I consider myself an Advanced Amateur on the art of smoking. I have used everything from a Weber, to what is now called an Ugly Drum. I have tried pellet and biscuit smokers with good results, but sorry, there's nothing like charcoal and wood. It always works when the electricity goes out. I have frequented this forum occasionally for tips, tricks, and smoker designs. I decided to become a member to do a little bragging and possibly pass on what little I know.

I, like many other real Americans, have always wanted a old refrigerator converted to a smoker. Most I have seen are either not very portable, or not charcoal/wood burners. I commandeered an old 1939 GE from the dump about 10 years ago for this purpose, and finally got the time do it properly. Something else about me... When I build it, I build it right or I don't build it.

Below are some of the fruits of my labor, and pocketbook. I designed, fabricated, welded, painted and polished for 4 weeks to "git er' done" and the best thing is, it works as good as it looks.

Here are the results of about $1,500 and 3 weeks labor.

1st burn in, 373 degrees for 5 hours, burned 30 Kingsford briquettes to start, burned about 5 lbs. of damp apple/oak mix. Shut down due to smelling too good and nothing cooking. It held temp well once dialed in. Close top damper to hold heat while adding fuel works well to hold in the heat.

2nd burn in / temp test. I was shooting for low temp for fish. 30 briquettes and 1lb+ wet apple wood chips and chunks. Up to temp in 30 minutes, top damper closed to 45 degrees, bottom damper closed 90%, air inlet closed 95%. Held low temp of 142 degrees for 2 hours, added 1lb +/- wet chips and held same for 2 more hours.

3rd test, Steelhead filet 158 degrees for 4 hours...results...

EXCELLENT!!!

Pics do not do the color justice, Despite the rumor, It's not always sunny in California. Kandy Apple Red and Jet Black with silver and red flake. Original handle and hinges on upper door were stripped of their nickel plating and original brass polished. Lower door was modified as it was just an access panel for the old compressor setup. Searched high and low for a cool handle...antique solid brass spring loaded imported from Scotland via ebay. I added solid copper pipe and fittings as handles/tie-down/bumper, plus it make it look cool. Accents the 3" copper chimney as well.

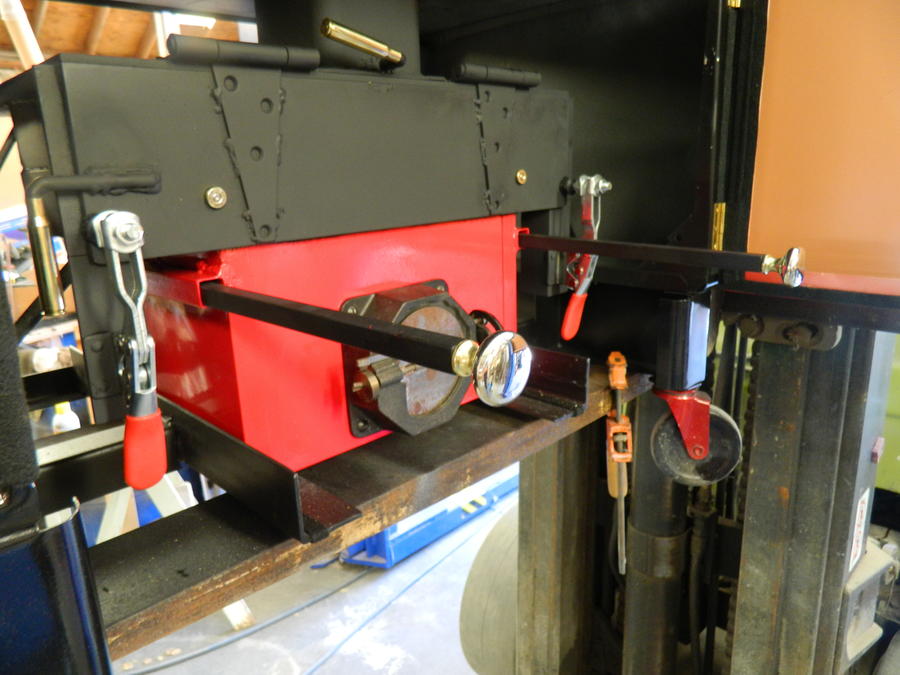

Old Bradley Smoker firebox worked great for this application, it has a 3" inlet with a thermostatic damper (not real impressed). It is sealed in 1/4" steel plate with a 3" outlet hole that has a manual damper

leading to the smoke chamber. Smoke chamber has a 3" open inlet hole from firebox.

Yeah, that's an empty riffle bullet casing for the damper control...God Bless America!!!

I added a brass drain and made a copper cup to catch the drippings.

Smoke box slides in and out easily with retractable handles.

heavy wall steel chimney leading to the smoke chamber, 3" damper fully opened...yes another bullet casing.

Digital thermometer with meat probe.

Back of fire box.

I pulled this copper pipe out from under a house that was built in 1941, It just seemed right to put it on a 1939 refer.

Fully insulated, I also built a steel frame inside the floor for support. This was my original firebox design...if failed...too much heat, not enough control.

All plastics and hazardous materials removed. Door trim pieces replaced with heave gauge stainless steel. Not shown, 8 expanded 22" x 14" stainless steel shelves with stainless steel brackets, spaced 3" apart for 2600+ square inches of cooking area.

Double sealed doors...black Nomex.

Better pic of color.

Toggle clamps seal firebox door that is sealed with Nomex.

My name is Matt, I'm 48, Dad to two phenomenal Daughters, and I live/survive in California (trust me, I'm not bragging on the Cali thing). I am self employed as a countertop contractor, so that means I have a lot of free time on my hands.. I also work on boats, hot rods and lots of other manly things. I have worked with my hands since grade school, My Dad was a General Contractor and would pull my brothers and I out of school to work with him. His words to the teachers were "you ain't teachin him $#*! anyway"!!! Although I consider myself a Professional builder of things, I consider myself an Advanced Amateur on the art of smoking. I have used everything from a Weber, to what is now called an Ugly Drum. I have tried pellet and biscuit smokers with good results, but sorry, there's nothing like charcoal and wood. It always works when the electricity goes out. I have frequented this forum occasionally for tips, tricks, and smoker designs. I decided to become a member to do a little bragging and possibly pass on what little I know.

I, like many other real Americans, have always wanted a old refrigerator converted to a smoker. Most I have seen are either not very portable, or not charcoal/wood burners. I commandeered an old 1939 GE from the dump about 10 years ago for this purpose, and finally got the time do it properly. Something else about me... When I build it, I build it right or I don't build it.

Below are some of the fruits of my labor, and pocketbook. I designed, fabricated, welded, painted and polished for 4 weeks to "git er' done" and the best thing is, it works as good as it looks.

Here are the results of about $1,500 and 3 weeks labor.

1st burn in, 373 degrees for 5 hours, burned 30 Kingsford briquettes to start, burned about 5 lbs. of damp apple/oak mix. Shut down due to smelling too good and nothing cooking. It held temp well once dialed in. Close top damper to hold heat while adding fuel works well to hold in the heat.

2nd burn in / temp test. I was shooting for low temp for fish. 30 briquettes and 1lb+ wet apple wood chips and chunks. Up to temp in 30 minutes, top damper closed to 45 degrees, bottom damper closed 90%, air inlet closed 95%. Held low temp of 142 degrees for 2 hours, added 1lb +/- wet chips and held same for 2 more hours.

3rd test, Steelhead filet 158 degrees for 4 hours...results...

EXCELLENT!!!

Pics do not do the color justice, Despite the rumor, It's not always sunny in California. Kandy Apple Red and Jet Black with silver and red flake. Original handle and hinges on upper door were stripped of their nickel plating and original brass polished. Lower door was modified as it was just an access panel for the old compressor setup. Searched high and low for a cool handle...antique solid brass spring loaded imported from Scotland via ebay. I added solid copper pipe and fittings as handles/tie-down/bumper, plus it make it look cool. Accents the 3" copper chimney as well.

Old Bradley Smoker firebox worked great for this application, it has a 3" inlet with a thermostatic damper (not real impressed). It is sealed in 1/4" steel plate with a 3" outlet hole that has a manual damper

leading to the smoke chamber. Smoke chamber has a 3" open inlet hole from firebox.

Yeah, that's an empty riffle bullet casing for the damper control...God Bless America!!!

I added a brass drain and made a copper cup to catch the drippings.

Smoke box slides in and out easily with retractable handles.

heavy wall steel chimney leading to the smoke chamber, 3" damper fully opened...yes another bullet casing.

Digital thermometer with meat probe.

Back of fire box.

I pulled this copper pipe out from under a house that was built in 1941, It just seemed right to put it on a 1939 refer.

Fully insulated, I also built a steel frame inside the floor for support. This was my original firebox design...if failed...too much heat, not enough control.

All plastics and hazardous materials removed. Door trim pieces replaced with heave gauge stainless steel. Not shown, 8 expanded 22" x 14" stainless steel shelves with stainless steel brackets, spaced 3" apart for 2600+ square inches of cooking area.

Double sealed doors...black Nomex.

Better pic of color.

Toggle clamps seal firebox door that is sealed with Nomex.