Thought I would post up what I do with natural casings. I use naturals 99.9% of the time when making sausages be it sheep or hog casings. I get compliments about how the casing are very delicate and have a perfect snap when you bite into the sausage. I believe the quality of the casings is part of it but how you handle the casings is another step towards a tender bite. Natural casings usually come packed in salt, wet salt or a salt solution. Casings in a salt solution require short soaking periods changing the water frequently where as casings packed in salt take lengthy times from days to weeks. My 36-38mm casings from Wolfson's come in this solution and I normally soak for a few days before using them. If I don't soak them for a few days and use them the same day (not removing the salt saturated in them) they tend to dry out quickly, not be as elastic, turn a darker color on the stuffing tube and sometimes stick to the tube and cause blow outs..... I have had great success when casings become fully washed and pliable. The casings need to be able to stretch without breaking making them thinner when the sausage is stuffed into them. I usually stuff sausage at the brink of it tearing.

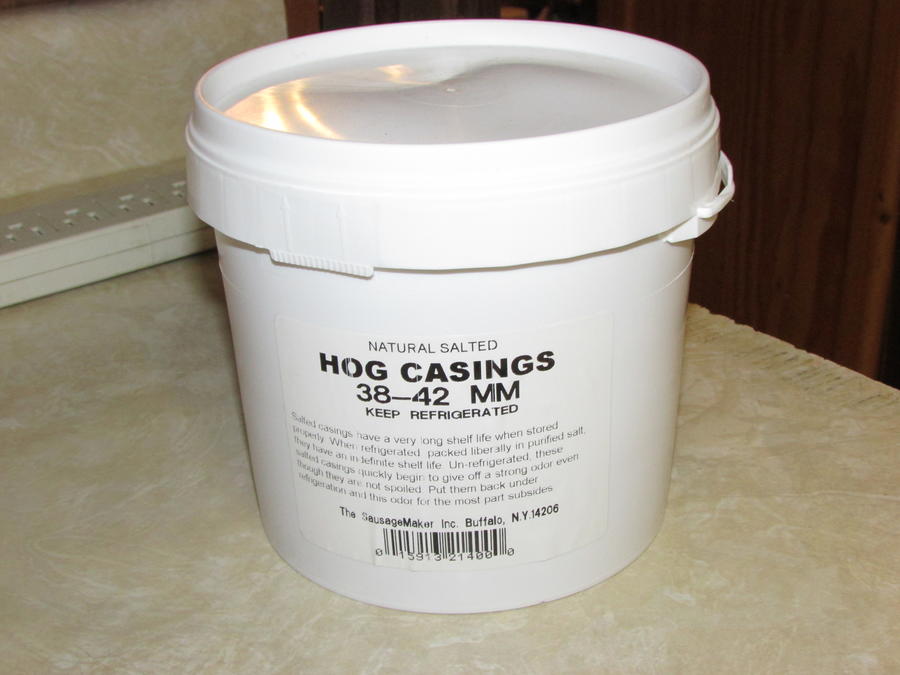

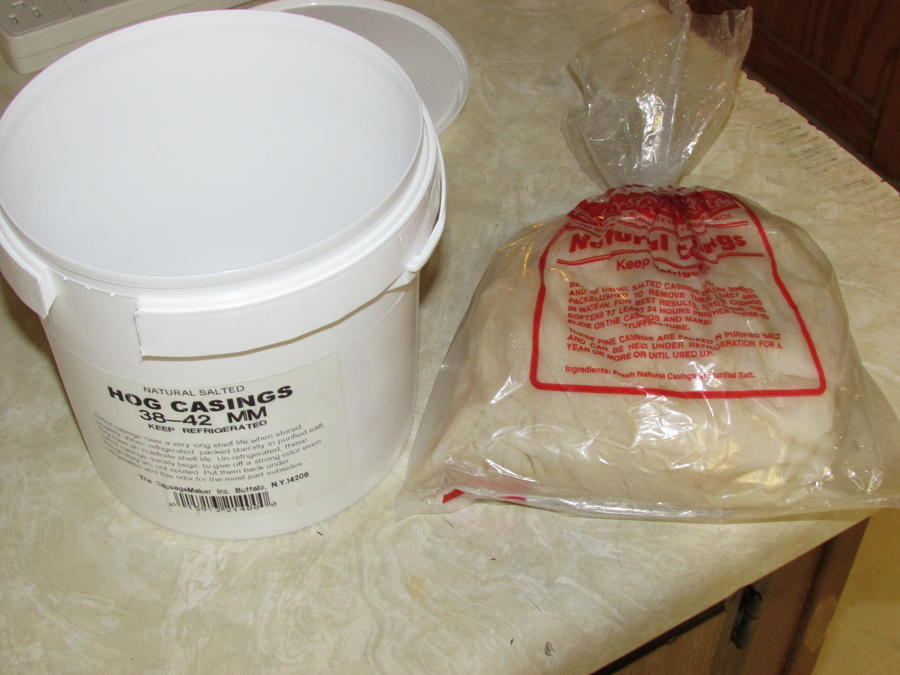

Here I am trying (first time) new casing out I bought from the sausage maker. They are 38-42mm and came in a wet salt brine. not a salt solution brine.

not much liquid but they are wet

Place them in the container and add some fresh water. Change the water frequently during the course of the day and return them back to the fridge.

After soaking them for a few days in the fridge they are softening up

Once they are clean and looking silky soft I remove them from the container, discard the excess water and place the casings back into the container and add 1/2 cup of non iodized salt to the casings, mix and store in the fridge for future use. The casing will have become so saturated with water you will not need to add any.

When ready to use the casings remove the whole hank from the container and place into a large bowl of cold water and wash the casings like you were scratching your head changing the water several times removing the salt from the casings. You will see the casings have become saturated and are looking silky smooth and pliable..... Here you will be able to grab a piece of casing and pull it out of the hank in one whole section without tangling. Place it into another container of water and take what your going to use removing what you'll need. I usually pull 18 inches per lb depending on the size.

Here's how they look on the tube. Wet,soft, and pliable. They will be easy to stretch without breaking and wont blow out.

Take your unused casing, drain them, place them into the container for storage and add the 1/2 cup of non iodized salt and put back into the fridge. You can add 1 cap full of vinegar if desired. I usually do

Back into the container with a good shake and back into the fridge for next time

Over all the casings from the sausage maker were very nice. Good quality but a little pricey. I will use them again...

I stretched these to the max. Fat boys..lol

Thanks for looking