Hello everyone, I have been doing my calculations with the feldon bbq pit calc and wanted to make sure that I have done everything correctly.

I have a cylindrical cook chamber 43.3"x15.5" with a cylindrical firebox 15.7"x15.5"

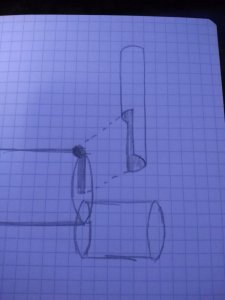

This gives me a recommended throat opening of 23.7sq in

If my calculations are correct the cut-out height that connects the firebox to the cook chamber should be 6.7".

Since that will also be the height of the baffle plate I will have only 1" left from the widest part of the cook chamber. I have read that the baffle plate should be at least 2-4" from the cooking grate so I would have to move the cooking grate up a bit sacrificing some cooking area.

Are my calculations correct?

Any help is greatly appreciated

Thanks in advance.

I have a cylindrical cook chamber 43.3"x15.5" with a cylindrical firebox 15.7"x15.5"

This gives me a recommended throat opening of 23.7sq in

If my calculations are correct the cut-out height that connects the firebox to the cook chamber should be 6.7".

Since that will also be the height of the baffle plate I will have only 1" left from the widest part of the cook chamber. I have read that the baffle plate should be at least 2-4" from the cooking grate so I would have to move the cooking grate up a bit sacrificing some cooking area.

Are my calculations correct?

Any help is greatly appreciated

Thanks in advance.