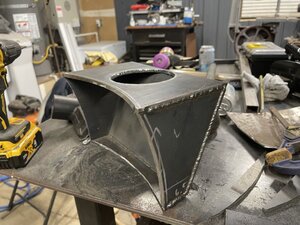

Hi all welcome to my 60 gallon build. I got this donor tank and I’m looking to build a simple RF smoker for my patio. I aspire to build a bigger cooker, and hoping to learn as much as I can with this build before investing into a bigger tank. I’ll be following the “how to build a reverse flow smoker ” thread for the majority of my build calculations.

I'll also be carting this around to local venues to support my smoked BBQ business https://www.instagram.com/stubbornbullbbq/

The tank came off of a decommissioned compressor. The steel is 1/8th thick… which I was hoping would be more once I cute the door off. Although the thinner gauge is not desirable, it should work, and at least is easy to cut .

.

I'll also be carting this around to local venues to support my smoked BBQ business https://www.instagram.com/stubbornbullbbq/

The tank came off of a decommissioned compressor. The steel is 1/8th thick… which I was hoping would be more once I cute the door off. Although the thinner gauge is not desirable, it should work, and at least is easy to cut

Last edited: