My original idea was to build a pizza oven on tis stamped concrete slab a good friend of mine poured for me. You can see from this picture that it sat for over a year without any progress. When I stumbled upon the smokehouse build I saw on this forum, my slab found a new purpose! We pressure washed the slab and started with a based of fire bricks for the fire box.

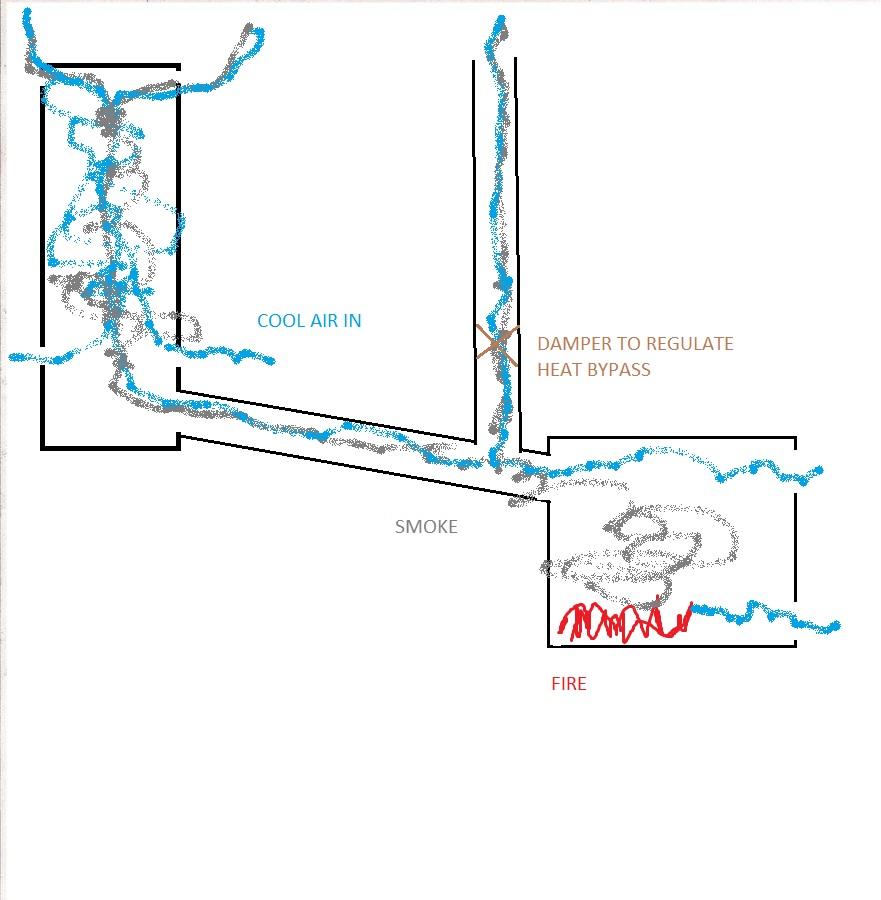

I didn't and still don't have any formal plans for this smokehouse except for the one in my head...which wasn't necessarily a good thing and it took me longer to make progress this way. With a rough idea and minimal block laying experience my plans started to take shape. Instead of using metal pipe as I have seen others do, I chose to use a piece of 8" ceramic flue pipe that is 24" long. I was concerned that this may be a little too close and that I wouldn't be able to cold smoke, but that hasn't been an issue. I also purchased split faced blocks for a more rustic look.

The flue pipe is at a slight uphill angle. I only went 3 courses high with the cinder blocks and filled all four corners with redi-mix and inserted j-bolts to tie the base plate to. We have some fairly strong winds in AR from time to time and I didn't want my smokehouse to be in the neighbor's pool...

We also started around the fire box with some bricks to give it a nice look. Jumping way ahead, I used some red clay dirt dug from my yard to fill the entire space around the fire box and flue pipe to act as an insulator. I made some cob from the clay and straw to seal the end of the fire box around the flue pipe. I used refractory cement on all the fire bricks. Do you know how hard it is to find a Barrel Stove door in AR? As good fortune would have it, I went on a business trip to Wisconsin and found my cast iron door at Menard's for $35. I threw it in my checked baggage and was expecting to have to pay an overweight charge since the thing weighed 25 lbs. by itself but for some reason I got away with it!

The next step was to find something stout to cover the firebox with that I wouldn't have to worry about for a very long time. I came up with a piece of 1/2" steel plate that worked nicely! I placed some bricks on top of the plate and leveled it up with more clay.

Once this was done I poured a slab over the top of it for the wood storage area.

From here I began framing it up using treated lumber for base plates and 4 x 4 posts and spruce for the walls because it's cheap.

I couldn't wait for it to get completely finished before I started a fire in the fire box with the assistance of my little helper! The top of the slab only gets a little bit warm even with my hottest fires.

I covered the outside completely with Western cedar fence pickets from Home Depot and screwed everything together with deck screws. I also cut batten boards to cover the spaces between the fence pickets to minimize and leakage and so I could better control the air flow. I didn't make a chimney, but I left one of the roof boards loose and I use it as a slide gate to control the air flow. I completely coated all exterior surfaces with boiled linseed oil.

I hope this build inspires someone else to try a project like this on their own! All together I've got about $400 in this little project but in my opinion it has already paid for itself! I have been able to smoke cheese by keeping the heat at 100 to 125 and cook brisket, ribs, or chicken at temperatures from 250 to 275. My son accidentally got the temperature above 350 so I know I have some capability up to that range.

Got smoke???!!! Thank you for looking!!!