My last try at cold smoking bacon was somewhat of a failure.

http://www.smokingmeatforums.com/t/251120/bacon-fail

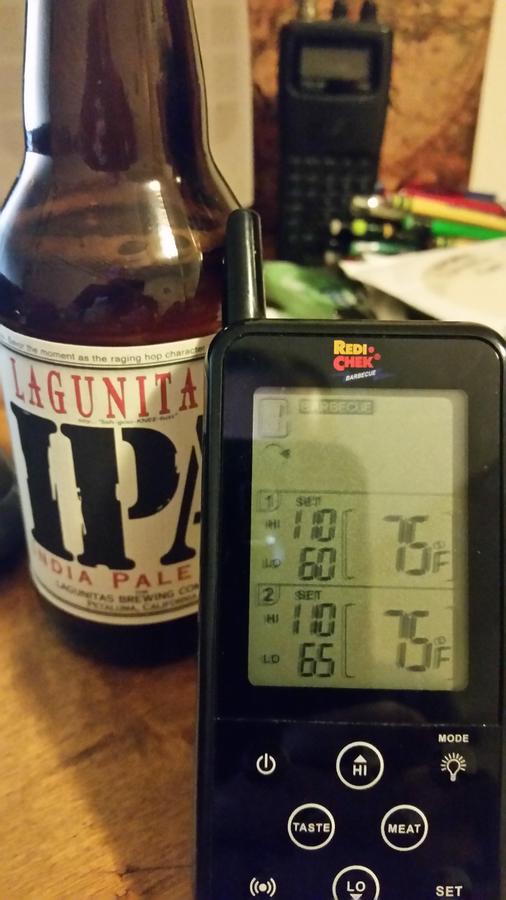

I have modified my smoker and will do another try tonight with Todd's apple pellets. Let's hope it turns out better than last time.

Longer pipe from mailbox to smoker, around 20 feet. I also drilled 3 one inch holes for ventilation in the top side of the smoker in addition to the three ½" holes I had from the beginning.

Small test slab of belly that will go in the smoker in about 1 hour. If this one is a success I have 10lbs. more to go.

http://www.smokingmeatforums.com/t/251120/bacon-fail

I have modified my smoker and will do another try tonight with Todd's apple pellets. Let's hope it turns out better than last time.

Longer pipe from mailbox to smoker, around 20 feet. I also drilled 3 one inch holes for ventilation in the top side of the smoker in addition to the three ½" holes I had from the beginning.

Small test slab of belly that will go in the smoker in about 1 hour. If this one is a success I have 10lbs. more to go.